If changing infill percentage “fixes” things, then you’re likely overexruding.

It really calls for a good calibration. Ryan has links on the site, the teaching tech stuff- if your printer is dialed in you would be getting good results at varying layer heights, infill percentages, number of shells, etc.

I´m printing a calibration cube right now and I´m planning on printing a few more tests today. Maybe a speed test and a temp tower.

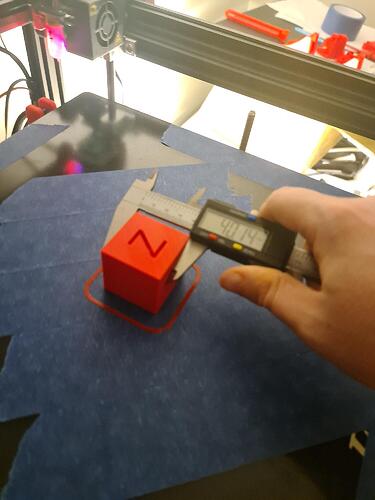

I did print a 30mm cube and x,y and z were all in the 30.0x range. I´ll post the results from the calibration cube here in a new post.

Are you using ironing? And monotonic top/bottom order?

And are you adjusting flow to 0.9 for PLA?

Was that at 0.3mm layer height? What infill?

My first thought was a slicer setting, like nozzle size was wrong. But that test cube looks ok.

The cube does look good. I am thinking about replacing the z rods though to get rid of some Z banding/ringing.

That was with 0.2 layer height and 10% infill. I haven’t tried 0.3mm layer height today yet. Trying to get the most out of the red filament before it runs out. Then I am changing to black or orange. Haven’t decided yet.

I guess the logical thing (like Spock) would be to try 0.3mm layer height again and see what happens?

Could I have a 0.4 nozzle and print 0.6 walls? ![]()

Or is that impossible? And perhaps a stupid question?

I did test prints for 0.3mm and 0.4mm layer height. Both work and I think that I like 0.3mm layer height better then 0.2mm.

I was planning on printing the core in 0.2mm layer height but now I might go for 0.3mm or even 0.4mm layer height.

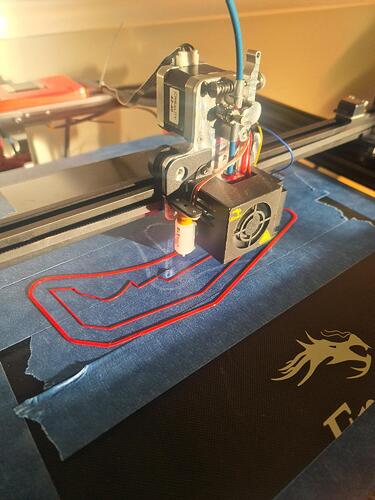

Trying the skirt and outlines on the core, I think I am ready to print it. I just have to change to a new filament with a different color.

Getting some nice first layer for the core, printing in orange pla. I did a testprint and the bed was off in one of the corners so I am glad that I cought that uneven bed with my testprint.

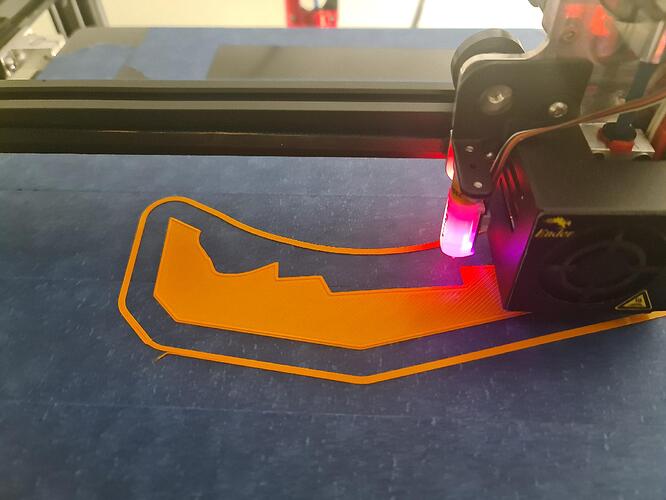

Now 17h to go before the core hopefully is printed in good quality in 0.3mm layer height. Seems to take around 125m of filament.

Good luck! See you on the other side ![]()

This is by far the longest print I have done, 17 hours and 125m of filament.

I am letting the build plate cool so I haven’t inspected the core yet.

Thinking if I should print some parts in orange or change the color of the filament to black.

Is PLA waterproof? I have some tape residue and I am wondering if I can rinse the PLA core in warm water?

What do you think is the best way to clean blue tape of 3d printed objects?

Cutting some pipe, here is the 600mm scrap of my 2000mm 25mm OD tubing.

Testing the braces and they slide on better then they clip on.

It is waterproof. I thought about printing decorations for my fish tank so I left some in a tub for over a year and I couldn’t see anything wring with it. (I decided not to make fish tank decorations afterall).

Isopropyl alcohol removes the tape residue well. I used to keep a tupperware to soak them in. The LR core would not fit though ![]() .

.

Hi, thank you for your reply.

I am glad that I decided to reprint all parts, maybe I have one or two days more of printing before I have all the parts.

Instead of starting a new thread, I have two questions related to the core:

The m8x40mm screws, can they be fully threaded?

And the 608-2rs ball bearings, can they be 608-2rs economic? Where economic is 1/3 of the price and it says “not noice tested, not suitable for electronic motors”.

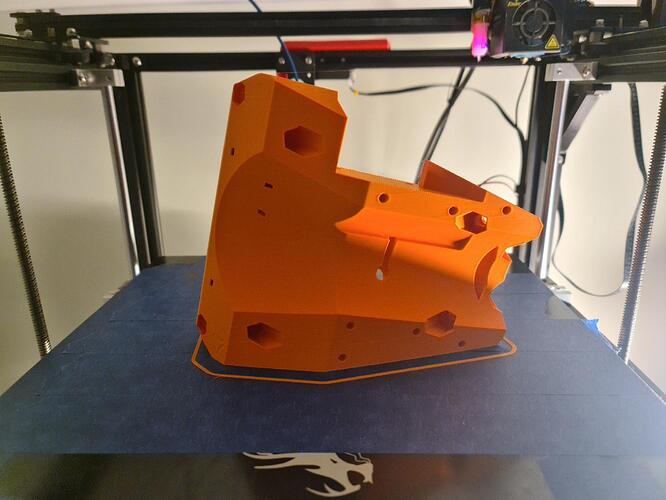

That looks solid!

Would you be able to take a pic with the focus on the part and the layering? I don’t think we’re getting prints that clean but would like to see a clear comparison since you’ve been doing a lot of fine tuning for this.

Hi,

of course I can do that. I would rate the print a 8/10. There were some underextrusion on the backside and some blits, also on the backside. Overall, I am happy with the print and with the ender 5 plus. It´s proving to be a workhorse.

The core is printed in 0.3mm layer height and I think between 70 and 80mm/s. If I would reprint it, I would go for 60mm/s.

Yes.

Well…I think I make a ton of mistakes but I do not notice myself fixing them unless I have to do it 3-4 times. So not an expert just a long time users so quirks go unnoticed. I got so good and bed leveling on the fly I fought tooth and nail not to add it to printers for years. Now that I finally have it i feel like an idiot for not doing it sooner (well it only makes sense with physical leveling as well).

It is really becoming a problem when I make a new machine. I fix things as I go and don’t notice, unless it is kinda major. The beta team really shines for things like this.

P.S. This is a pretty cool thread, lots of issues and solutions and a conclusion with some flawlessly printed parts… I love this place!