I’m pretty sure all you’ll have to do is build a plotter. Integrating real time drawing looks like it will be pretty easy. There will likely be a lag since you can draw faster than the plotter can move, but it will be about as real time as you can get.

I already have one with fluidNC, so I’m quite close already!

There are so many interesting things to do with this project.

![]() I don’t know about that but something cool could be done in that space. I made that specifically trying to have physical controls but for this a touchscreen might be better.

I don’t know about that but something cool could be done in that space. I made that specifically trying to have physical controls but for this a touchscreen might be better.

You can do this in Javascript with a canvas. This is how my virtual joystick jog WebUI v3 extension works. Using that extension as is in XY jog mode might be fun. Could swap out some buttons to raise and lower the pen and maybe even swap pens.

I have a bunch of questions on sizing. To not look absurdly large on a wall in my house, I’d want to size it for a 24" paper roll.

Width

Based off numbers in this thread, this looks like:

| Paper (in) | Board (in) | Extrusion (in) | Rail (mm) | Print (mm) | Print (in) |

|---|---|---|---|---|---|

| 36 | 49 | 48.125 | 1000 | 865 | 34 |

| 30 | 43 | 42.125 | 848 | 715 | 28 |

| 24 | 37 | 36.125 | 696 | 565 | 22 |

Height

Height appears to extrapolate out like this. There’s some rounding in the mm to inch conversions. I’m probably looking at 28 inches of drawable height.

| Rail (mm) | Print (mm) | Print (in) |

|---|---|---|

| 1000 | 920 | 36 |

| 900 | 820 | 32 |

| 800 | 720 | 28 |

| 700 | 620 | 24 |

So, my questions are:

- What is the height of the backboard? I see that it goes all the way to the bottom but not all the way to the top. Any reason for that? It seems it could go to the height of the bracket holding the belt and if the Y extrusion was long enough, it could go that high as well.

- How much width is available on the right side to mount the power supply? It appears to be whatever the width of the Jackpot is.

- What is the size of the wood frame? It appears the boards are about 5 or 6 inches wide. I assume being that wide is necessary to hide things. How deep is that? I’m trying to figure out how far this will come off the wall. I would be curious to see a picture from the side. How is the frame attached? Is it directly attached or just mounted to the wall over top of it? Is it removable in case you need to fix something?

The height of my backboard is not really based on the plotter’s frame dimensions. It is what I was left with when I cut a sheet of MDF in half. I mounted it all the way to the bottom to protect the lower X-Axis motor, idler and belt when it was set in the vertical position in the easel that I put it in during the build and testing (see pic). Ideally, I would have made it 50 1/4" (for a 1000mm vertical rail) so it extended up slightly past the upper X-Axis motor, idler and belt. That said, the minimum height of the backboard would be the same as the height of the frame, which is 46 1/8" inches for a 1000mm vertical rail. In that case, you would need to flip the surface mounts (Part B) so the mounting screw tab faced inward instead of outward, so the screws had something to attach to. (see pic)

You have even more space because the gantry would ride over the supply when it was on the extreme right. There is 1 3/4" clearance under the gantry and the pen carriage is about 5 3/4" in from the frame extrusion, so those are your limits. It’s really just a matter of aesthetics. Technically, you could even mount it on its side so it would be more hidden. The supply that I linked to in the BOM is about 4" wide, and the wood frame that I built has 4 1/2" of clearance above the drawing surface. You would need to consider lighting (if I did that on mine, it would contact the led strips inside the frame, but they could be positioned to accommodate).

The overall size of the frame is 51 1/4" H x 51 1/4" W x 5 5/8" D. All the pieces are 5 1/4" wide (based on a standard 1x6 board width). I planed them all down to 3/8" (10mm) to make it lighter. It would be very heavy using 3/4" boards. If you did leave the boards at 3/4", then obviously the frame size would be 3/4" wider and taller and 3/8" deeper. The frame cleans things up but doesn’t really hide much unless you are standing 6’ away and looking straight at it. I attached some wood blocks to the backboard in the upper corners for the frame to sit on. Then 2 small screws on the top (only visible from above) hold the frame to those blocks. To remove the frame, take out the screws, remove the paper (it slides through slots in the top and bottom of the frame), and disconnect the led lighting power leads from the Jackpot board. The plotter is held on the wall with a French cleat. That creates about 1/4" of space between the wall and the back board, but the frame mounts flush with the wall (see pic), so it hides that space.

To confuse things a bit more - if you were really concerned with the size, you could trim 2" off all my width dimensions (maybe 3) and still have room for the motor and idler brackets on each side of the upper and lower X-Axis linear rails. You would need to modify the toolbin accordingly, as well as the face of the wood frame (i.e. if you trimmed off 2" in plotter width, the wood frame face would be 4 1/4" instead of 5 1/4" and the pens would need to sit 1" closer to the left frame extrusion. The vertical dimensions are what they are. There is no extra space on the extrusion that holds the Y-Axis rail.

[Picture1]

The only reason I mounted the backboard so low was to I could set the plotter on the easel peg, keeping the belt free to move during build and testing. One of the surface mounts is circled. Those two screws need something to go into, so technically you could rotate them 180 and decrease the height of the backboard to match the height of the extrusion frame.

[Picture 2]

French cleat in the foreground.

I was planning on posting some more details on the wood frame in a future post.

Someone made a way to draw a pattern and export the files. Similar to sandify. I haven’t had time to see if there is any way integrate something like that into sandify just yet. Real time would be much harder. But pretty fun.

Open sauce also had an etch a sketch that would take your photo, convert it to a line. Then draw it on the etch a sketch:

I just put together the javascript required to do “real time” plotting from a tablet. It was remarkably simple. Just a small web page with some simple scripting. I’m trying to figure out how to take a video of it in action. Hopefully will upload something later today.

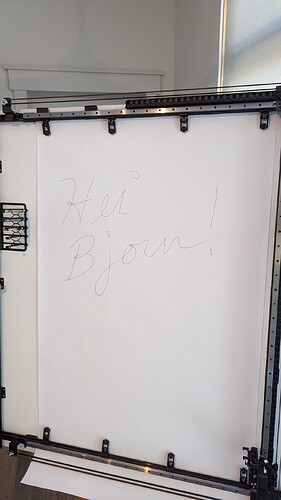

Here you go @turbinbjorn. I put it together quickly, so it needs some polishing. Might be a way to process the gcode to speed things up a bit. As is, the pen moves point to point, so even if you drew a perfectly horizontal 700mm line across the page, the program still sends 700 move commands to the plotter. The drawing speed is set to 5000mm/min and obviously there is still quite a lag. Too bad I can’t shake the tablet to erase the page. ![]()

Wow, impressive!

Wow! This is amazing! This is all dots then? What about drawing vectors, like freehand Inkscape? (Sorry… ![]() )

)

Technically, that can be done, but I’m not sure to what end in this application.

I changed the audio track in the video so, instead of me breathing, you can listen to a piece of music by Norway’s most famous composer, Edvard Greig. I thought that was appropriate. (you might need to refresh the page)

And, I wouldn’t describe it as all dots. The pen only leaves the paper when the finger is lifted off the tablet. But, in the g-code, the longest line segment starts and ends on adjacent millimeters, so the moves are either 1mm (on the horizontal or vertical) or 1.41mm (square root of 2) on the diagonals. The g-code can only accept lines and simple arcs, so the best you could do is convert the curves being drawn on the tablet to Bezier or quadratic, then convert those curves back to small line segments to send to the plotter. You would achieve a smoother plot but probably wouldn’t gain much in speed.

Edit: Your biggest result would be that the kids (or adults) drawing on the tablet would be convinced that they were better artists than they actually are.

This is cool. You could try decreasing the resolution and see what happens. What I’ve seen is that you never reach the max feedrate unless you’re sending commands at a fast enough rate to keep the planner buffer full. How is this determining when to send the next command?

The JavaScript is sending them at the same rate the lines are being drawn on the tablet, so real-time. Obviously, they get buffered somewhere but I couldn’t say where for sure. Meaning, I don’t know if FluidNC is metering them via the web socket or accepting them real time and buffering them on the ESP32. At any rate, I suspect that the slowness is more related to the directional nature of the line vectors. For instance, because of the pixelated nature of the drawing canvas, even though a horizontal line might look straight, there are times when there are 1mm changes up and down and each one of those 1mm lines has a vector perpendicular to the line itself. So, there are a lot if very small square corners.

Edit: Well, maybe not all square corners but at least 45 degrees off.

I also often breathe while recording clips! Always a little embarrassing, glad we are more people in that boat. Grieg is not a bad replacement ![]()

Grieg’s house is in Bergen. Drove past it when I was there 30+ years ago. For some reason that memory has stuck with me. I really liked it there. Maybe I should relocate to Bronnoysund. Sounds like my kind of place

Brønnøysund is so beautiful, you can’t imagine. It’s not like Lofoten with its jagged mountains, it’s more a combination with a huuge archipeligo, mountains of all sorts and a lush coast line.

But, unfortunately, Brønnøysund is like the High School prom queen. Everybody likes her and finds her very beautiful, but if you try to engage in a meaningful conversation, there’s no one at home… I actually moved back home when I was at the end of my twenties. I missed the landscape and the nature. But I actually got depressed, there was nothing to do there, except for looking at the nice view… moving to Tromsø was a wise decision.

![]() That is a fantastic analogy. It actually makes me want to live there even more.

That is a fantastic analogy. It actually makes me want to live there even more.

A place with a beautiful view, nothing to do but get lost in the woods and no one to talk to except a deer, or a fox or a bear… That’s my kind of place.

OK, back to the plotamabob…

There were some questions about the wood frame. Obviously, there are many ways you could improve the aesthetics of the plotter so do whatever, including no frame at all. I wanted to do something to help keep little fingers from getting into the lower belt, so this is what I did. It’s not perfect, but it helps. I used 1x6 boards for all eight pieces of the frame. They were planed down to 10mm to reduce weight. I was worried about the miter joints on the frame’s face opening up over time since I live in an area with fairly large humidity swings from one season to the next, so I experimented with a clamping system that has worked really well.

These are pictures of a maple frame that I am making for a plotter that uses 30" paper. The corner joints on the box are simply glued and fastened with 18-gauge finish nails. I mounted a 30A power switch in the top corner. Also, notice the slot along the top back for paper. There is a similar slot on the bottom.

Here you can see the miter joint brackets on the frame’s face as well as one of the angle brackets used to hold the face assembly to the box and finally some led strip brackets. The four pieces of the frame’s face can be disassembled and removed.

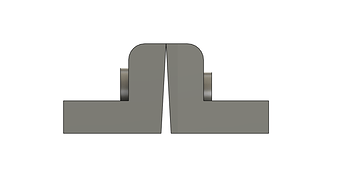

This is a side view of the miter brackets. Each side is attached to the frame using three #6 x 1/2" screws. The faces of the brackets are angled, so when the socket head screws are tightened, the miter joint is pulled tight. The bracket also keeps the wood faces flush when humidity swings encourage wood movement such as cupping and twisting. If the joint starts to open, a simple turn of the socket head(s) will pull it back together. If you use the uploaded 3d models, take notice that the two sides of the brackets are different. One side is intended for the hex nut and the other for the socket head.

The led strip brackets have a small tab on the back designed to tuck wires under to keep them organized. If you have all the lights on one switch, then you won’t need that, but if you have the top & bottom on a different switch as the sides, then it will come in handy.

3d Model files:

wood_frame_3dmodels.zip (32.7 KB)