Two teardrop trailers made with a lowrider v3.

Together with my brother we build a teardrop trailer thanks to the LR3. After making our own design in CAD we started by making a scale model.

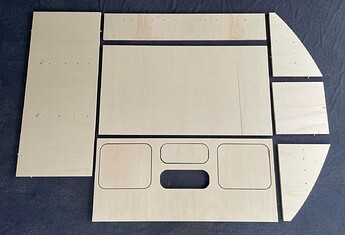

Then we were ready to start building the full scale model. In the shed of our grandma we had enough space to set the LR3 up to cut full sheets. We used an old but sturdy table tenis table as our worksurface, which works great!

We used Poplar ply since it is very lightweight and has a light color which we expected would look nice as the interior. It turns out poplar is pretty difficult to cut. It is so soft and light that it burn very fast. Upcut bits made the cuts look bad. What worked out was using a two flute straight bit of 6mm. Most cuts were done with a 6mm doc and 15mm/s. The results were very good and accurate.

Building took around 5 months. Mostly since i’m still in uni and thus most had to be done during weekends and after school hours. Some more images can be seen below aswell as the end result.

Final result:

After building the first one, we enjoyed it so much and we saw a lot of potential for improvement. Also in the actual CAM part. The first version was made to be assembled using mostly tung and groove connections and also needed a lot of manual work afterwards. The new version uses dowels to and has pre drilled holes. This cuts down the cutting time drasticly and is more forgiving then tung and groove. Assembling the second one was almost as easy as an ikea flatpack furniture.

Hoping to finish this one this week, second one only took a month

Thanks @vicious1 and everyone who helped for making such a cool and usefull machine!