3 posts were merged into an existing topic: “V1E GO” Maker Faire May 2024 - info page (see other thread for submissions posts only)

Designed and printed a ‘Hatch Clamp’ for the Kayak. It’s based off of Cam latches designed for boats. The idea is that there will be one of these mechanisms on each side of the hatch. Turning the latch will clamp to the thick closed-cell foam that I’m using for the bulkhead on the kayak.

I may have some tuning to do once the final hatch/bulkhead is installed. I’ll print the final parts out of the same purple ASA that the rest of the stuff on the kayak are printed out of.

I wanted the knob big enough to easily turn if I have gloves on. The problem with most cam latches is trying to get your fingers in there to open them.

Hello, my name is Markus and I come from Tyrol.

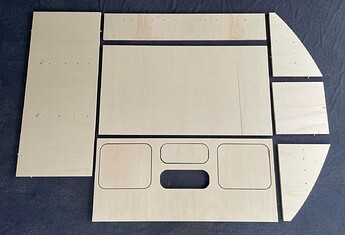

I built a house several years ago and unfortunately a dead space was created right in the stairs. There was just 30cm of space and that had always bothered me, so after some time to think about it, I planned a box with large, long 80cm drawers.

I started Fusion 360 and got started. After some trial and error, this is what I came up with. I’m actually very happy with it.

Finally, I milled matching baseboards and engraved them with my initials

milled on my converted mpcnc

nice greetings from Tyrol

Hello my name is Travis from up in bc Canada. I see a lot of super awesome projects in here what a cool idea to get everyone’s brains thinking.

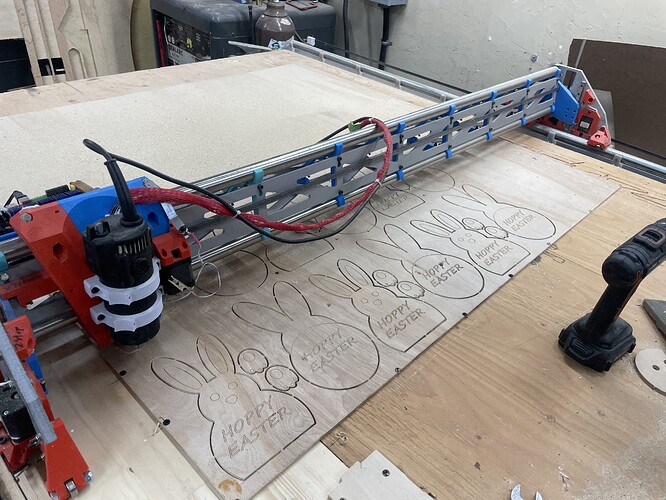

Well I don’t have my recent projects quite done and my coolest one I think was from December. Here is a really fun memory of what the lr3 can do and bring your fam jam together.

I even designed them this time.

I wanted a 3 legged stool so it wouldn’t wobble and came to the realization that the V1E logo would be a good basis for the seat. I started this back in January with my still novice CAD skills. I went a bit overboard on parameters and found that changing some parameters would break it. So, I let this one go for awhile. Last weekend, I decided I was just going to make it work. Mistakes were made but I’m happy with the outcome. Maybe someday I’ll redesign it to make the legs less busy and extend out the legs for more stability.

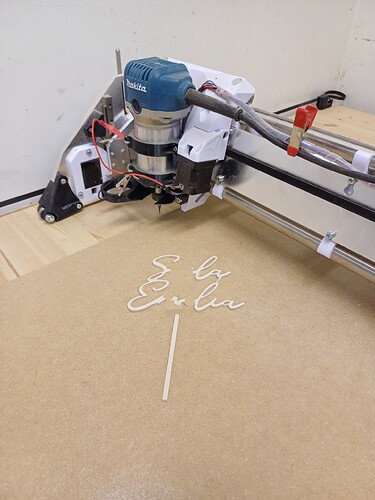

Two teardrop trailers made with a lowrider v3.

Together with my brother we build a teardrop trailer thanks to the LR3. After making our own design in CAD we started by making a scale model.

Then we were ready to start building the full scale model. In the shed of our grandma we had enough space to set the LR3 up to cut full sheets. We used an old but sturdy table tenis table as our worksurface, which works great!

We used Poplar ply since it is very lightweight and has a light color which we expected would look nice as the interior. It turns out poplar is pretty difficult to cut. It is so soft and light that it burn very fast. Upcut bits made the cuts look bad. What worked out was using a two flute straight bit of 6mm. Most cuts were done with a 6mm doc and 15mm/s. The results were very good and accurate.

Building took around 5 months. Mostly since i’m still in uni and thus most had to be done during weekends and after school hours. Some more images can be seen below aswell as the end result.

Final result:

After building the first one, we enjoyed it so much and we saw a lot of potential for improvement. Also in the actual CAM part. The first version was made to be assembled using mostly tung and groove connections and also needed a lot of manual work afterwards. The new version uses dowels to and has pre drilled holes. This cuts down the cutting time drasticly and is more forgiving then tung and groove. Assembling the second one was almost as easy as an ikea flatpack furniture.

Hoping to finish this one this week, second one only took a month

Thanks @vicious1 and everyone who helped for making such a cool and usefull machine!

@vSeccelen I think you could use a sign to finish off your build. That camper is awesome!

I made this address marker before out of plywood and didn’t treat it at all. Obviously that fell apart quickly. So I remade it out of cedar. Still has issues since my joinery resulted in a warped back but it should last quite a bit longer this time around

Does this count or do i need to share the t shirt whrn complete?

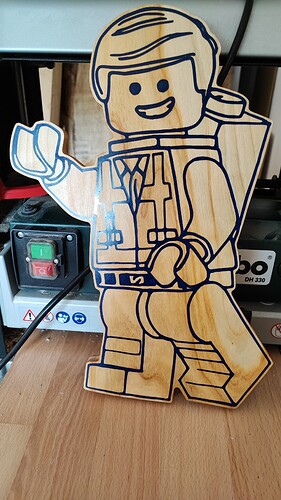

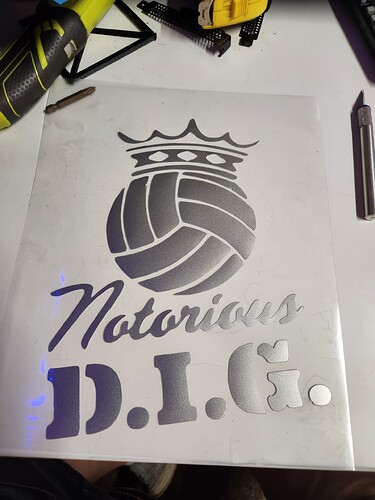

Started with Inkscape Trace of a picture my daughter found. Went to Estlcam, ended up using engraving, but only one pass.

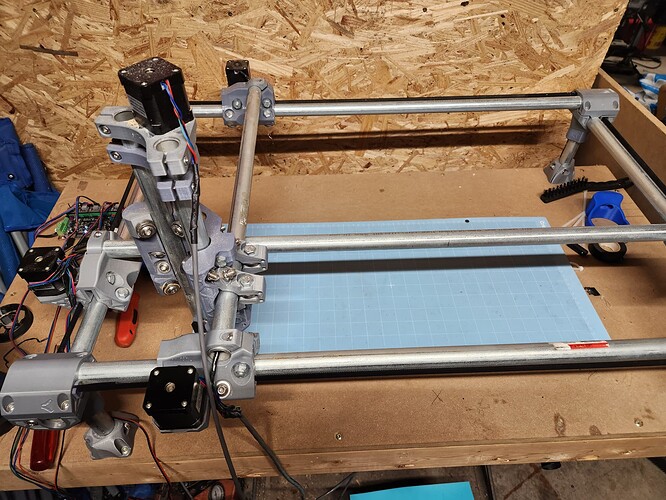

mpcnc, cheap drag knife, Lots of patience, and a large cricut cutting mat.

So, I was lining my print to the left. I then moved to the center. (I had to make 6 of these). Moving to the center allowed me to use Fluidnc to move x 100mm to the left and then I could remove replace easily! I did this prior to Fluidnc, and I can definitely say Fluidnc makes this Much Easer.

Also I just found the documented Drag knife process. I should have reviewed it prior! I used engraving, should have set my tool better and used hole or part. That way I could have used the lead in as shown.

https://docs.v1e.com/tools/drag-knife/

Buttttt, in the end my teen is happy and that is all that counts ![]()

Newly discovered fossil! Note the very unusual overlay of the V1E logo onto the fossilized trilobite. According to Dr. Ifounda Rock, BS Ph.D, famed archeologist and coprolite expert from the East Nowhere Institute, "This discovery is one of the most important of the 20th century. The superposition of the V1E logo over the trilobite indicates their contemporaneous existence during the Cambrian period. This puzzling result, if ever understood, will be the most significant archeological find since the Great Pyramids, and demonstrates the existence of V1E systems for far longer than previously believed. "

Rock showing contemporaneous V1E and trilobite fossils.

Trilobite closeup

V1E-Trilobite fossil with US Dime for scale

[Now, for the rest of the story… in case there is anybody still reading, this piece is, in fact an engraved stone using my laser-equipped Burley MPCNC. The laser is a 5W Sculpfun S9, mounted in place of the router on the Burley. The controller is now the MKS DLC32 which directly handles the gcode generated by Lightburn. The artwork is a vector image. Laser conditions were 100mm /min and 85% power. The trilobite was engraved in a single pass and the logo was engraved in 3 passes.]

Grapes on Barrel Carving

This entry is a carving done on walnut using my my Primo MPCNC and is about 12 inches in diameter. It depicts the end of a barrel with a cluster of grapes and grape leaves as well as sections of grapevine.

The carving was done using multiple steps in EstlCAM v11. The first roughing step was with a 1/4" upcut router bit. This was followed by 4 “finishing cuts, starting with a 1/8” router bit followed by smaller ones, finishing with a 0.25mm ball end bit.

Several closeups of sections of this carving are shown below.

A project like this takes a lot of planning. The same image was used to create a prototype of the project at a smaller scale. This is shown here :

This example again had a roughing cut followed by several finishing cuts, with the final on being done with a 0.25mm ball end bit. (note that the horizontal lines are scratches that appeared because the substrate was not perfectly flat on the spoilboard.

The features on this prototype are quite small, and and although this piece is not eligible because it was created in 2023, the following image uses a dime to demonstrate the scale of the work and the accuracy capability of the MPCNC.

OK, that about wraps up the first ever V1E GO Maker Faire!

Thanks, everyone for your awesome entries! And thanks, @dwkisker, for rounding things out with humor and an impressive CNC carving entry.

@vicious1 and I will be looking over the entries choosing winners! Again, thanks everyone!

OK, the winners have been announced! Read about it here:

Thanks for getting this all set up and running the show Doug!!!

It was great to see all the entries. I love to see the range of projects you all are working on. From simple to insane, each of them make me crazy proud to have helped enable you getting your hands dirty and try something new!

Absolutely! Thank you!!!

Congratulations for the winners.