I guess so, a lot of builds on YouTube even use a drill (which I think is stupid), my motor has got 1.1kw and 1400rpm, which is roughly 1.5hp. It’s three phase power though.

The hardest part to find was the coupler. I didn’t want it to be belt driven because I wanted it to be low profile. ![]()

Direct drive? I think the belt adds some vibration dampening and allows for a sort of clutch if something goes wrong and you need the slip.

How well does it work? I have seen drum sanders used a lot for things like end grain cutting boards.

It works incredibly well, made it exactly for what you suggest, cutting boards. If you look at commercial machines by Jet etc. they always use the direct drive, but have the height done via a main axis where the whole axis goes up and down.

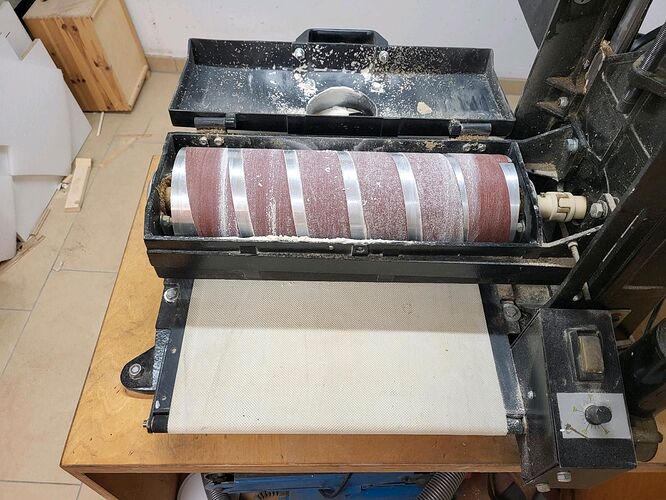

You can see it here for instance (ignore the fact that the seller did something weird with the sanding paper):

This is a cheap version with a plastic coupler, mine is steel and has got a rubber thingy in the middle to allow for dampening and a little play.

The little noses make sure that it only goes up and does not bend down into the table, which the first version always does.

Started a new, better height sled thingy with steel rods for guidance and stability.

What on earth were they thinking with that sandpaper application!?

Would you be willing to share your design?

Sure, but basically I slapped leftover wood together. There are no plans. I am going to have a build video in a few weeks. ![]()

I can see that I put a BOM together though.

This is awesome! I’ve always felt drum sanders are crazy overpriced for what they do.

The very fancy ones have a cantilevered end, so you can do larger pieces in two passes. But having it built symmetrically would make it much easier to trust that it was square.

Nah, the fancy ones are oscillating and the very fancy one are 10 000€ and so big the turning is not needed. ![]()

Thanks for your carving entry in the V1E GO Maker Faire!

Old vs. New.

Okay, done, I guess. ![]() Now I still have to make sure the plate the workpiece is on is less wobbly. I might go to my woodstore and look for nice leftovers. I want one of those black plywood boards.

Now I still have to make sure the plate the workpiece is on is less wobbly. I might go to my woodstore and look for nice leftovers. I want one of those black plywood boards. ![]()

First results are in. I took the most shitty glue up I’ve ever done and the sander works better than I’d ever imagined.

I just stopped at some time, but I could have had it all smooth like a baby’s behind.

WHOA!!! That is nuts!

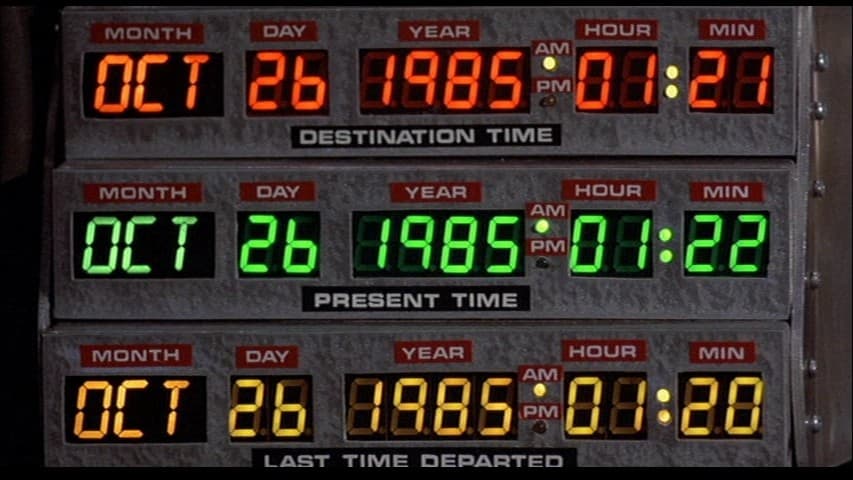

That faceplate gives it such a cool look. Kinda like it is out of that show “Lost”, old school or futuristic at the same time.

A post was merged into an existing topic: “V1E GO” Maker Faire May 2024 - Submissions/Entries

Back to the future was definitely my first thought too. Although I am guessing it resembles something from a naval base too. The GPS receiver is a nice touch.

@vSeccelen, that trailer is awesome. It is something I’ve always wanted. But probably won’t ever start making. Congratulations on the build. Are the plans some commonly available thing or did you design them yourself?

Ditto on that! Also, thanks for not skimping on the photos. Love seeing the journey and how it all came together!

Thanks! The plans are made by myself. We couldn’t find a design we really liked. Our design is mostly made to have close to no waste material. The full build only uses 5 full sheets of ply with maybe a quarter of a sheet as waste.

Wow! What is that outside material? ![]()

The outside is made from aluminium composit material, in the netherlands it mostly goed under the name of dibond. Durable and lightweight ![]()