Hello guys/gals. I am a machinist apprentice in Switzerland and I am so fascinated by machine tools, that I’ve decided to build my own 3 axis CNC milling machine, but i need serious help. First off, sorry for my grammar, english is my 3rd language.

I have bought the V1 Jackpot CNC Controller with ESP 32. It is currently equipped with TMC2209 drivers, but I want to use DM556 drivers because I considered to use NEMA 23 stepper motors → higher voltage. I already have the UGS (Universal GCode Sender) and Fusion 360 / Mastercam to make CAM programs. I am planning to use 6 steppers (each 3,6V DC, 3,0A and 1,2 Ohm) and a MeanWell PSPA-1000-48 power supply.

Now to my questions:

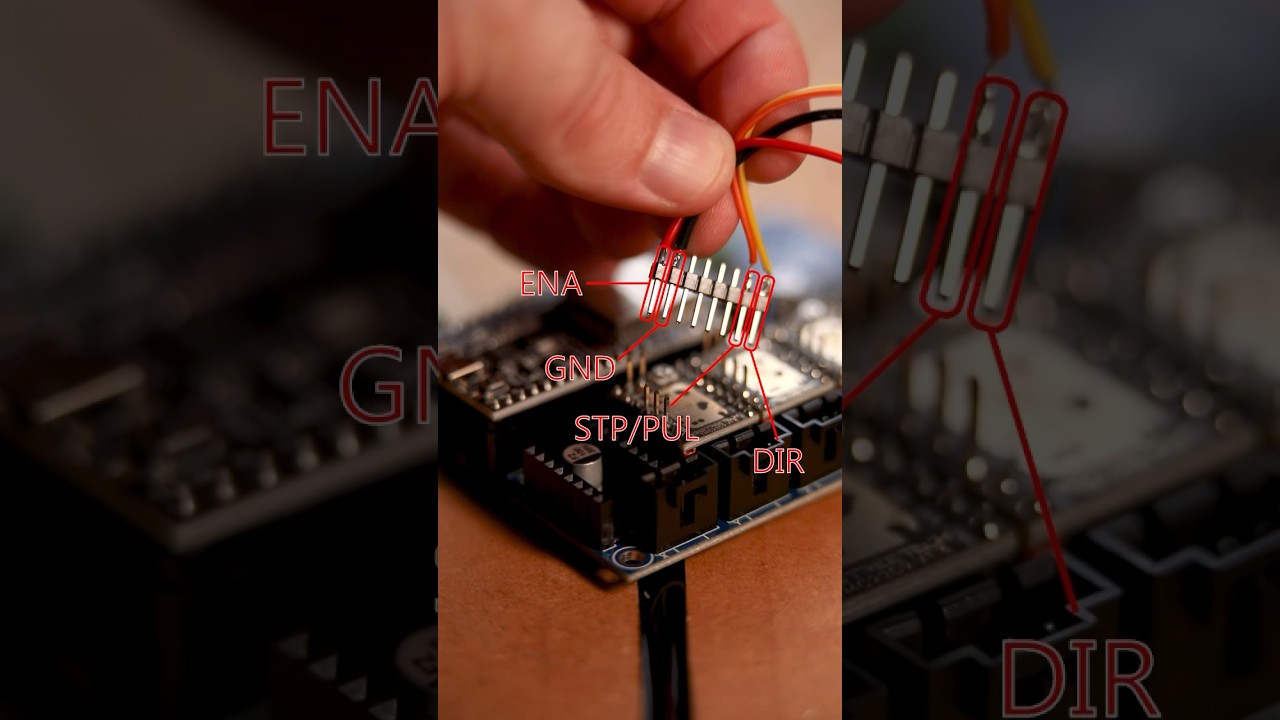

- How do I connect the DM556 drivers with the board?

- I know that my drivers need external power supply, but does this apply for the steppers too?

- Two stepper motors and drivers for each axis (X,Y,Z): How do I change the orientation / layout of the board?

- VFD: How can I turn on the spindle with M-Code like M3 / M4 and turn it off with M5?

- Can someone please explain the inputs and output on this board and what they could be used for? Havent found anything related or easy to understand.

- Can I use 1 power supply for the board, the 6 steppers and their drivers? Or do they each need their own power supply, and if, please recommend models or requirements.

I am eagerly waiting for your responses. Any help is welcome. Thanks!