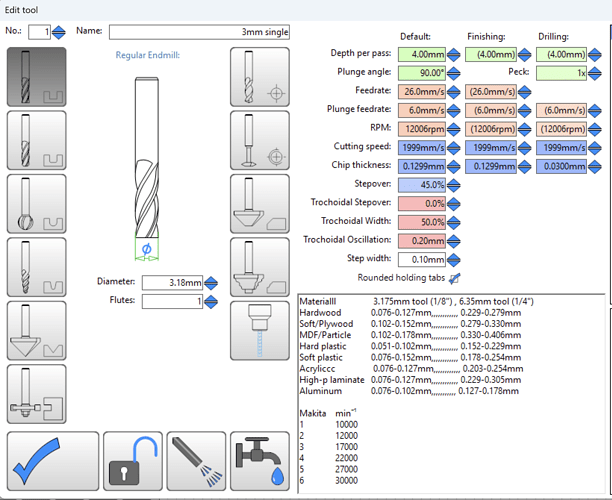

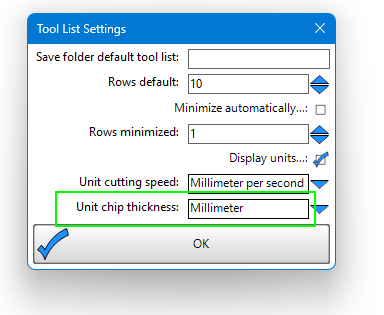

I was messing with a chip load chart, trying to make a good way to play with the numbers. I ended up converting some table screenshots into a CSV and copy/pasting it into my tool’s ‘comment’ section like in the screenshot below… I did have to do some tomfoolery like extra letters and hella commas to get everything to line up. You can line things up with spaces, but they get wiped out after you save:

Table taken from the following guide, which assumes DOC = 1x tool diameter.

DOC of 2x tool diameter = chip load * 0.75

DOC of 3x tool diameter = chip load * 0.50

“ if the depth of cut is increased to around twice or thrice the tool diameter, the values in the table should be decreased by about 25% and 50%, respectively”

Makita speeds are taken from the manual. I did stumble upon this excellent post where a guy measured his Makita with a tach, also shows you the notches for 10k, 15k, 20k: Makita Router Tach Speeds - Machines (Original/PRO) - Onefinity CNC Forum

Table copy/paste:

Materialll 3.175mm tool (1/8") , 6.35mm tool (1/4")

Hardwood 0.076-0.127mm,,,,,,,,,,,, 0.229-0.279mm

Soft/Plywood 0.102-0.152mm,,,,,,,,,,,, 0.279-0.330mm

MDF/Particle 0.102-0.178mm,,,,,,,,,,,, 0.330-0.406mm

Hard plastic 0.051-0.102mm,,,,,,,,,,,, 0.152-0.229mm

Soft plastic 0.076-0.152mm,,,,,,,,,,,, 0.178-0.254mm

Acryliccc 0.076-0.127mm,,,,,,,,,,,, 0.203-0.254mm

High-p laminate 0.076-0.127mm,,,,,,,,,,,, 0.229-0.305mm

Aluminum 0.076-0.102mm,,,,,,,,,,, 0.127-0.178mm

DOC of 2x tool diameter = chip load * 0.75

DOC of 3x tool diameter = chip load * 0.50

Makita min⁻¹

1 10000

2 12000

3 17000

4 22000

5 27000

6 30000

Now you can play with feeds and speeds to your hearts content ![]()