@Mattk331 , I may need to come visit and check out your set up some time. Although I think I saw someone was is in spring hill which would be closer.

It was 30°f here this morning in Cantonment (Pensacola). Supposed to be 18° Tuesday morning. I had the propane heater running in the garage earlier while I was surfacing. Luckily all my printers are inside. The humidity is way too much to deal with trying to print in the garage. I even have to dry it and keep it all in dry boxes to print from to keep it usable.

Ok, I need guidance here. I am running klipper for dummies (sonic pad) on my 3dprinter because I dont really know much coding other than dead languages. I’m about to order electronics stuff for my build, and dont have any clue what the better option for boards and firmware is. I see a TON on the tube about fluidNC but I cant make sense of it all.

I am looking to mostly work with wood/mdf but definitely want do aluminum and maybe down the road if I can get it set up right, then thin steel.

Am I better off with the SKR or the Jackpot? Is there a third option that I am going to get more expandability from? You would think as an Electrical Engineer I would be better at this, but my brain is much from psych meds and injuries. I promise I’ll get up to speed over time, but for this one choice I really just need someone to decide for me and I’ll go from there.

I’d recommend the Jackpot as it’s the newer board and has the most ongoing development and more users daily.

What kind of expandability are you looking for?

Go with the Jackpot!

thank you sir. I have no clue what expandability but it seems someone is always trying to figure out how to push these machines one step further.

Maybe a Florida meet up for V1 machine owners? ![]()

Id be game, but the pesnacola guys are like 8 hours from me and miami is another 6. Its a big state!

As far as I know I’m the only one in Pensacola area. And yes 8hrs is a bit far lol. Sad thing is I work out of Louisiana and Can get from Florida to my office in Houma, LA in only 4 hrs

@GrumpySarge is up in the handle too

so after watching @azab2c video and then going through the build thread… I think I am going to steal his idea and make it work fore me. I have an 8ft long, 32" wide bench that might be the strongest part of my entire house. Its also almost directly on the opposite side of the wall from my dust collector so that’s convenient. Now, I will build the LR3 to work on that bench at the correct X size to fit a full MDF sheet which we all know is like 49.x inches.

Then I will also build a set of removable rails for my big workbench that will allow me to install them every time in the exact same location. When I need to work bigger and 2’x4" I will simply move the LR3 to the bigger table with those removable rails installed.

I was looking at my table saw/assembly table today and I cant have rails the full length of the bench because it will interfere with my cross cut sled.

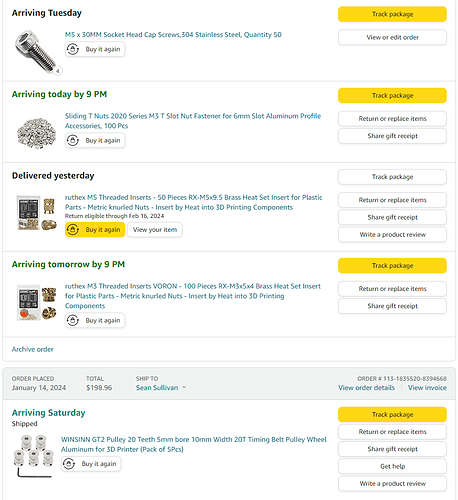

I has also started laying everything out for post processing. I run my nozzle hot so I get some very minor stringing that a quick pass of the hair dryer takes care of quickly. Didn’t realize how many parts I have made in relatively short time. Now the fact I’m on my third roll of filament makes more sense to me.

You’re making great progress.

That sounds like a great starting spot to lay out a good table for your build. Good idea.

I am starting to test fit everything together and I think I under estimated the fun in putting all these parts together. I might need to make another one after this just so I can put it together.

Hell yeah! I have 2 of them. As much as I love using them to make cool stuff, I almost think I love the build more lol

Im waiting on parts for this and for my printer upgrade. From the looks of things, I’ll have printer parts before I have CNC parts. I have already made the decision to not take my printer apart until the LR is built, but its going to be pretty tempting. Going from cartesian to corexy with much more cooling and way better flow. Means I should be able to comfortably print my big layers at the speeds I usually max out my normal layers and with better precision.

Which design are you going with? or are you designing your own system?

quasi merc 1 Nobody does one for the 5s1. Every other E5 on the planet has a kit. So Im kinda going off the merc set up, but I have some customized pieces. I want to be able to fully enclose it. This enclosure inside of an enclosure thing is not my style.

Yeah I’m doing the merc one.1 but not going with an enclosure. My next MP3DP will be full enclosure I think

check this out before you get started

How does moving them to the front increase accelerations? And how can he say that it does when its not been tested on the printer???