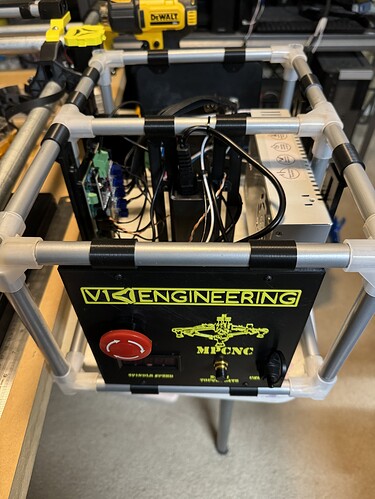

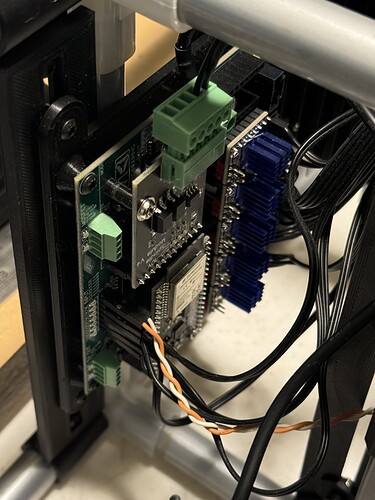

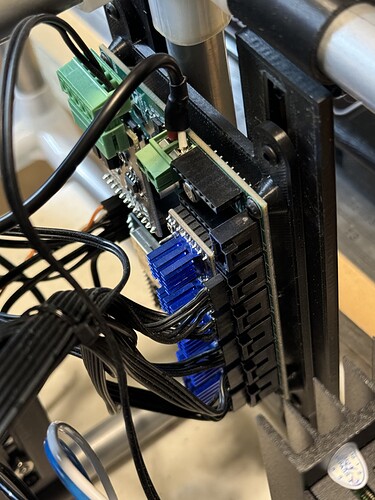

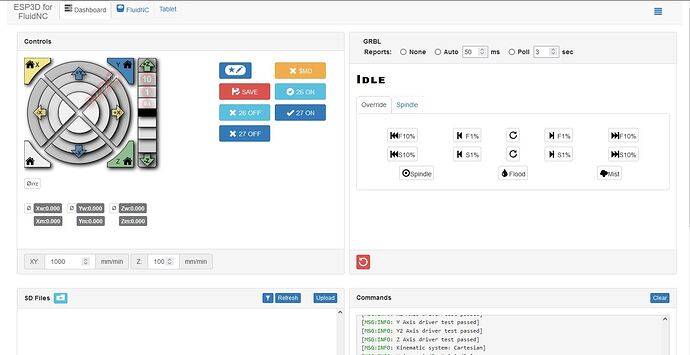

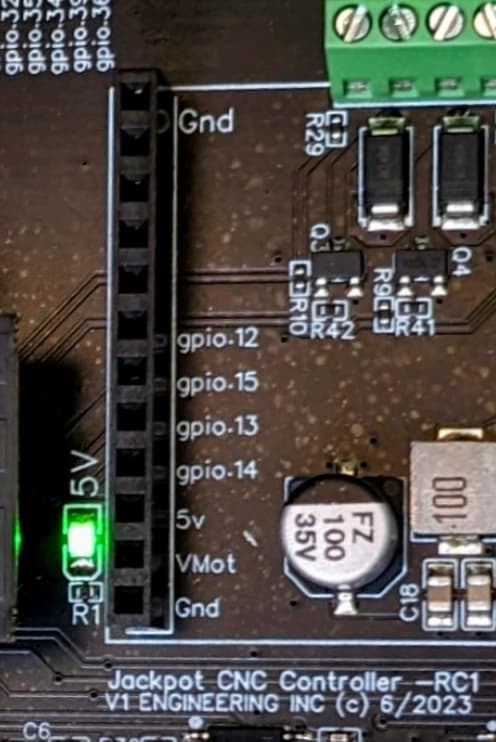

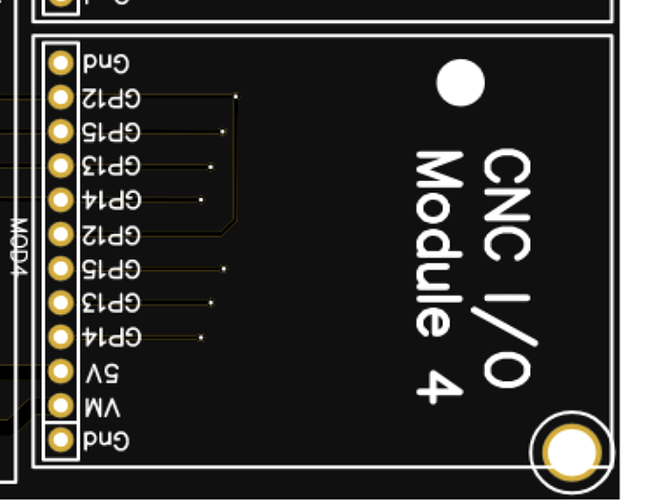

Got all of the control electronics wired up after I received the 0-10V Spindle CNC I/O Module on the mail. Need to do some serious reading on firmware change requirements and any additional wiring needed for that thing. Also remember reading something about having to calibrate it to actual 10V output via a potentiometer somewhere.

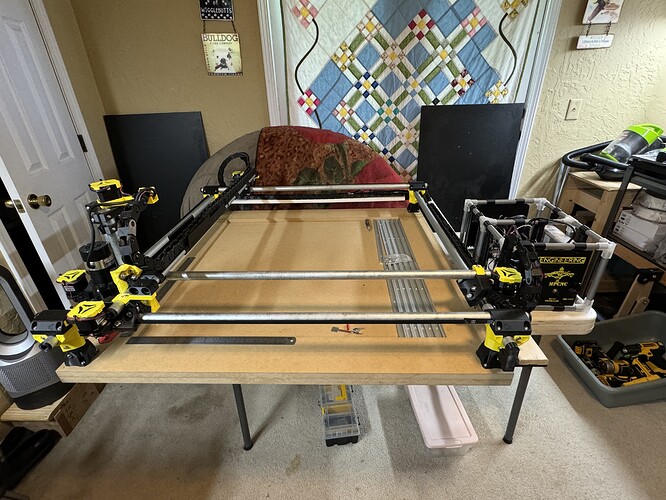

Debating adding a few 80mm 5V case fans but won’t need it as this will be living indoors with temperature control.

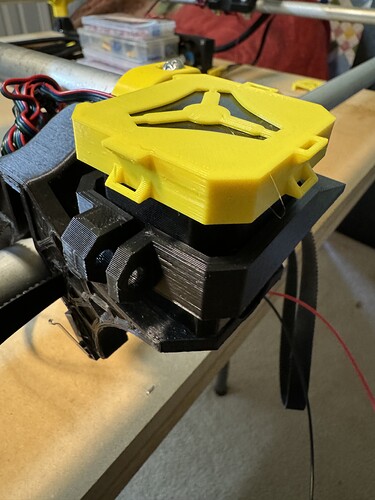

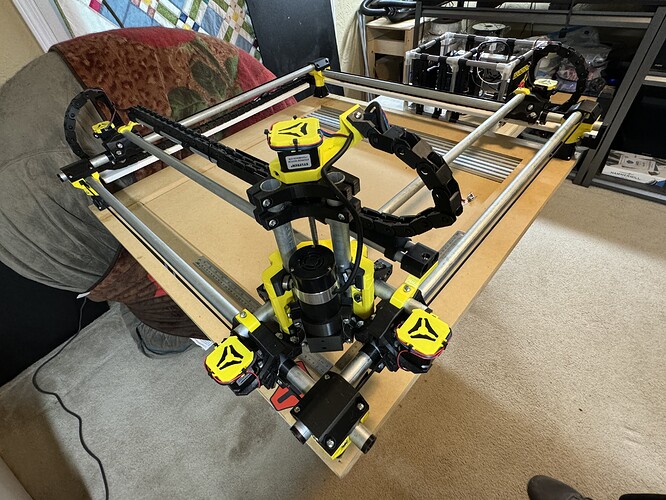

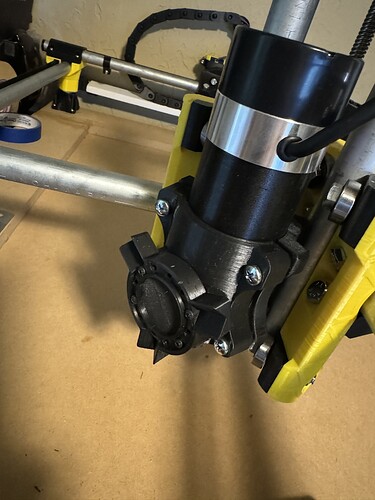

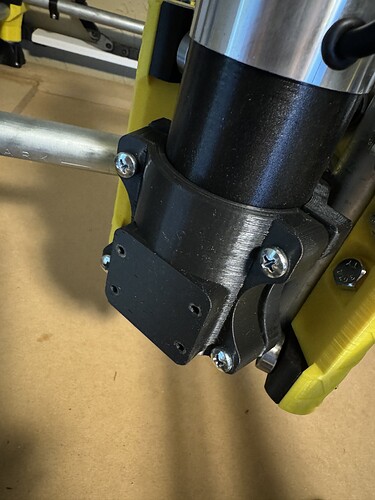

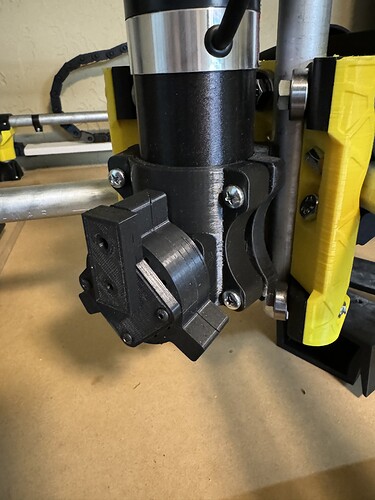

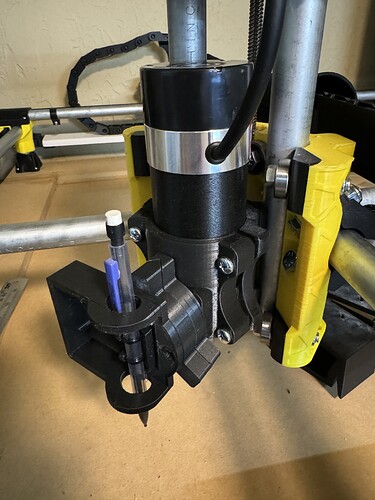

Also got a few bells and whistles printed and installed like stepper covers and stepper-mounted drag chain attach points.

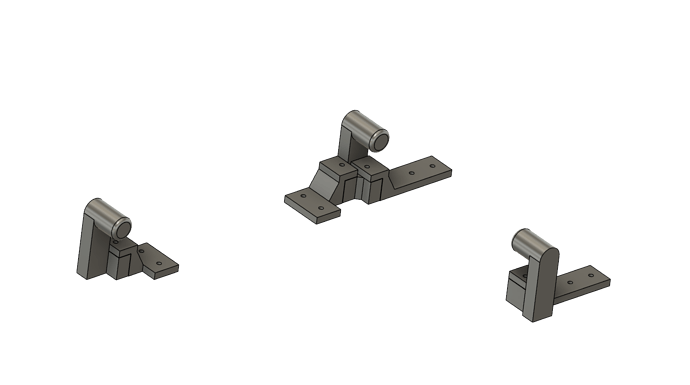

Got a vac hose mount coming up next that’ll mount on one of the Z-axis EMT pipes between the z-motor and z-coupler parts, just have to remix it for a 1.5-in vac hose.