Real and blue epoxy fill. Remove the hot glue and sand it flat tomorrow

Ooooh, that’s a great idea to prevent spilling. Hot glue. Genius. ![]() Gonna do that for my next try with epoxy as well. We are not really good friends yet.

Gonna do that for my next try with epoxy as well. We are not really good friends yet.

Much easier to remove than silicone caulk, just comes straight off with a chisel. I remove before sanding because it gets gummy through the heat

Stuck it down to my bench with blue tape and superglue sandwich, and used a carbide scraper to hand flatten. Then I went through the grits- 80, 120, 180, 220, water popped, repeated, 189, 220, then wiped with mineral spirits. After it dried, waxed and buffed.

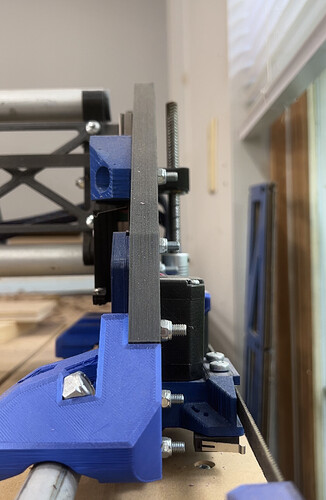

I posted this to my insta earlier…. And just saw my strut plates hanging out in the background, lol, just sitting there… hahahaha

So, went to run a laser job, and my left side Z stepper is making ‘dual up’ noises and as soon as I hit x or Y home, it fails.

I can home z, it works, then is quiet. But as soon as I move y or x it’s starts to make noises, and as soon as I hit y home, it fails. If I hit x home, I fails after it hits the switch.

New stepper, first step. Any tips while I wait, appreciated

I’ll post video once I get a link from my YouTube

I know the stepper failing is a low probability thing, given how they are designed, but my wiring has a fair amount of slack, so it isn’t pulling or pinching anywhere. Only other thing I can think of is the stepper driver. Maybe I should switch the right and left side stepper drivers, and see if the issue moves to the right side?

Any idea what the difference is between the v1.2 and v1.3 of the bigtreetech Trinamic tmc2209 uart drivers is?

I can find the 1.3 on amazon for delivery tomorrow (sorry Ryan) and wondering if they are compatible. I imagine they are. I can always send them back if not

I just remembered I left the lr3 on between jobs yesterday, and I never got to the second one. I ended up turning it off late. It was holding position around 7 hours or so.

I burned up a driver, right?

No I don’t think so.

Are your steppers warm? I have the current on the drivers set pretty low. You can add more current, but more importantly the steppers should stay energized once they move. The hold current is 80% the move current.

Try doing a simple gcode from a file,

G28

G1 X10 F900.

See if it acts differently. For some reason, either you do not have enough current or they are disabling after homing.

It really seems like you have a loose wire or something.

Nope, not warm. Been running perfectly until this morning.

Nothing loose in the box either- I double checked. Not sure how something would come loose, I have a fair bit of slack

I’ll try the gcode, but isn’t that just the same as sending console commands through the interface buttons? What would it be doing differently (asking to learn, I like knowing as much as I can about stuff)

Thanks Ryan

“Not enough current” could be a symptom of loose wire in the power jack plug, right?

I didn’t check that, and I’m putting kids to bed after their shower. I’ll check in about 45 minutes

Thanks

You can up the current until they are warm, what is it set at now?

The commands in the terminal stop so it thinks the program is over at each step, running it in gcode should keep them all on longer. I think…interested to see if it is different. We can up the holding current, up the time before it goes to holding current, or just bump the current all together.

No It would restart if that was the case.

You know what else could lead to a ‘not enough current’ situation

Plugging your 12v 1amp laser power supply into the 12v 2amp input of the skr pro board

I even have the ends of the wire color coded- silver aluminum tape around the 2amp supply cable.

I’ve been running on fumes with the kids yesterday and was excited to get back to the project and missed it, I guess

Need to verify, but looking at the video I posted, I’m 99.9% sure

Feel like such a freaking dummy

I never touched the pots, so whatever they were set to originally. Is there a benefit to tweaking them?

Good point about the loose wire, that makes sense.

Also interesting in how the two methods differ- that’s also pretty obvious (from reading the terminal box) but not something I appreciated until now

Thanks for the help Ryan

Nah, it happens. Good thing the power supply didn’t die.

All digipots, the ones on the board, don’t do anything in UART mode like we use.

Confirmed- A OK when I use the actual proper power supply.

Ooooffff. Feel dumb.

How do you tweak the current for the steppers, and what would the benefits be? Better ‘torque’ so I could increase my speeds a bit (currently self limiting to 30mm/s in hardwoods since I know that works, but a boost to 40-45 might be cool) ?

Thanks!

You found the issue on your own, after reasoning through possibilities.

That’s not dumb, it shows intelligence.

And you posted your findings which is a reminder for all the rest of us when we think about issues we’re having and what might some day cause us a problem with our own machines.

Thank you.