Dude, I made that arm…  The plans are available in the forum as well as a 4-part documentary on Youtube.

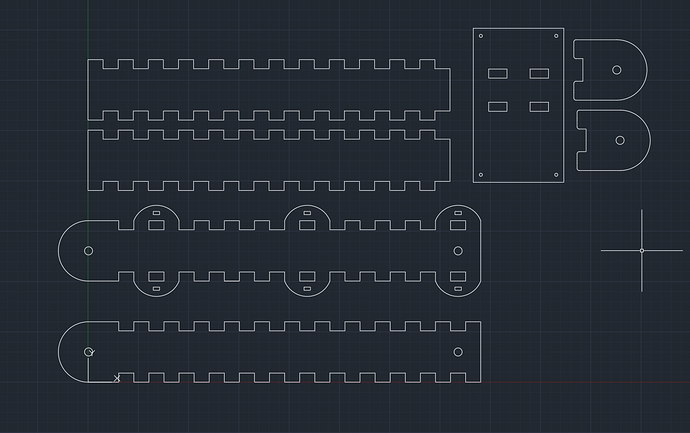

The plans are available in the forum as well as a 4-part documentary on Youtube.  Boom Arm Final

Boom Arm Final

For the one over the Lowrider I wanted to go easier, also a torsion box with a removable top so I can put the cables in, a pipe on the top (or better bottom, but it comes from the top) and then I wasn’t sure about whether it should be able to slide or not. At the moment I have got nothing sliding, the hose is just there and does it’s job without blocking anything.

This is the plan as of now. Top and bottom have rods as usual that hold the top down, the only part not glued.