Thanks

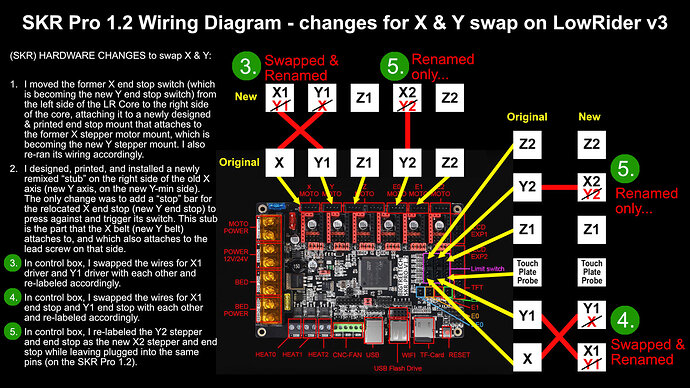

Sorry to revive an old topic, but I needed to revisit it in preparation for installing Jackpot board in place of SKR board, and still maintain my swapped X & Y axes. To help with that, I needed to refresh my mind on what changes had already been made in my wiring. I made the following graphic to better document those changes:

For sake of others who may wish to do the same with a Jackpot board, I aim to make a similar documentation for the Jackpot, which I will post over here:

It was requested that I share my config.yaml file that accomplishes swapping X and Y axes with the Jackpot board. Here you go! The attached zip file contains two config.yaml files, both with swapped XY, and one is BEFORE adding the Fluid Dial pendant, and the other is AFTER adding the pendant. Remember that whichever one you choose needs to be renamed to just “config.yaml”.

Hi Doug,

Thanks for the detailed procedure. In the time since you have posted it, the official V1 file has been updated to https://github.com/V1EngineeringInc/MarlinBuilder/releases/download/515/V1CNC_SkrPro_DualLR_2209-2.1.1.zip, and the newer version of Marlin uses somewhat different syntax.

I (think that I) have found the correct way to accomplish this in the newer release.

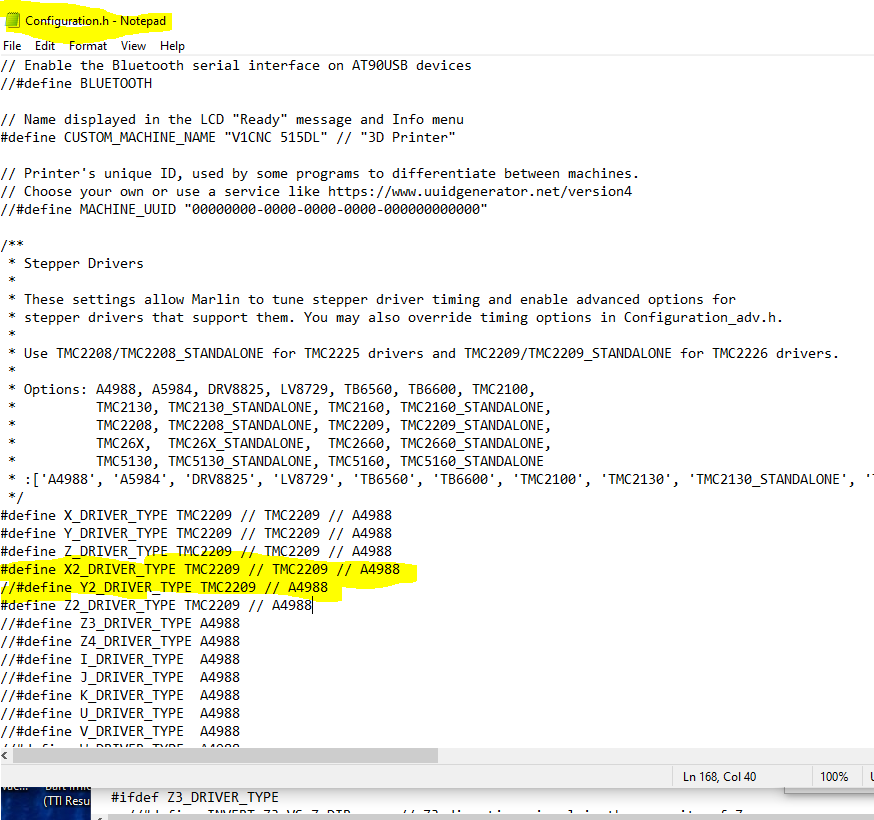

In configuration.h:

- Uncomment #define X2_DRIVER_TYPE, and edit to match the correct driver type (same as X, Y, Z, Y2)

- Comment out #define Y2_DRIVER_TYPE

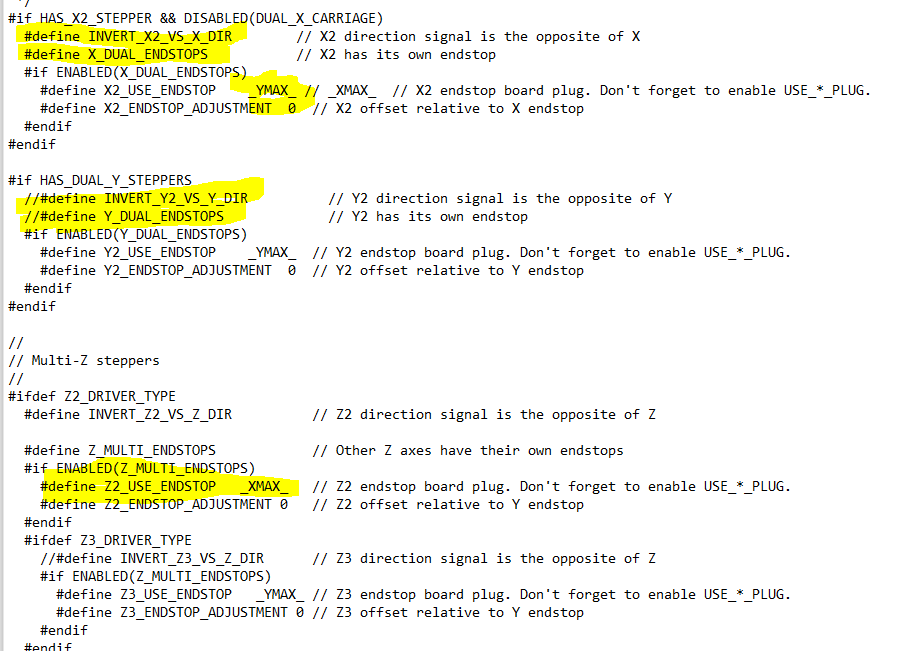

In configuration.adv.h:

- Uncomment #define INVERT_X2_VS_X_DIR

- Uncomment #define X_DUAL_ENDSTOPS

You shouldn’t need to do the next two items because of the IF statement, but I did them anyway - Comment out #define INVERT_Y2_VS_Y_DIR

- Comment out #define Y_DUAL_ENDSTOPS

- EDIT - Must also change #define X2_USE_ENDSTOP _ XMAX_ to X2_USE_ENDSTOP _ YMAX_

(Note that endstop X_MAX is already in use by Z2 endstop)

The above changes should change the E0 driver and endstop ports to be X2 instead of Y2. Wire accordingly.

Edit - tested this and it works, but you must also change the X2 endstop to use YMAX (see note above).

Found another item that may need to be edited…

In configuration.h - you will probably want to swap the bed size values, so that X is larger than Y

#define X_BED_SIZE 2440 //1220 // 200

#define Y_BED_SIZE 1220 //2440 // 200

BTW, instead of mirroring the gantry, I used side mounted belts on both sides, which allowed me to simply move the limit switches to the opposite side of the motors, and then swapped the belt holders around. Easy-peasy!