Hi all -

The machine cut the “nine” first, and cut to even depth pretty well.

However, when it cut the “thirty” it left stripes as you can see.

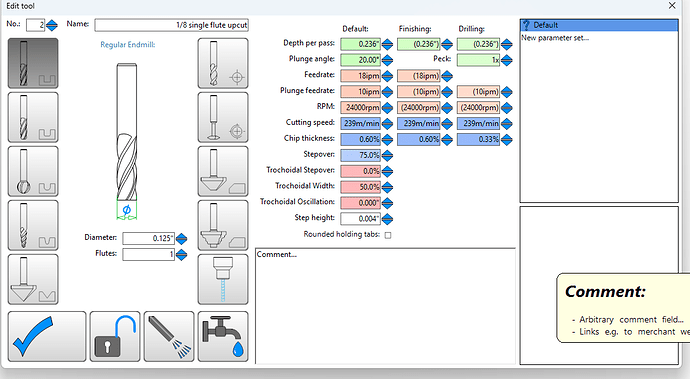

It was one continuous run. The CAM was written in Etslcam and has never previously shown this behavior.

Cut depth was .125" using a brand new upcut bit from V1. No damage to the bit seen.

Any ideas?

My thought is to re-write the g-code for just the “thirty”, increase the depth to .13 and see if it cleans up.

Thank you in advance.

dos

June 5, 2025, 1:27am

3

Looks to me like the core, or router bracket, might be rocking back and forth left to right. Perhaps the bearing bolts have loosened up.

1 Like

nstiesi

June 5, 2025, 8:08pm

5

yup, looks like classic “out of tram” (cutter not perpendicular to the table). The fact that the severity comes and goes would suggest the actual angle between tool and table is changing during the run, as Daryl suggested above.

Thanks everyone. This appears to have resolved the issue. As always, appreciate the support on the forum!

1 Like