What defines a Matte PLA? I always assumed Matte referred to the finish? If so does that make something like “regular” black PLA, stronger?

Matte is referring to the finish however the additives used to create the finish slightly weakens the filament compared to regular PLA

a bit of a tease there… ![]()

Some pros and cons :

I’d totally buy an MPFL (mostly printed fiber laser)!!

Easily my favorite channel on YouTube right now.

Wait doug can plasma cant he??

He and Ryan both can. But plasma isn’t good for something like that. And it’s real tough to get right on aluminum. Laser is the way to go for sure

Better either have a TON of time on your hands or be ready to open that wallet up REAL wide…

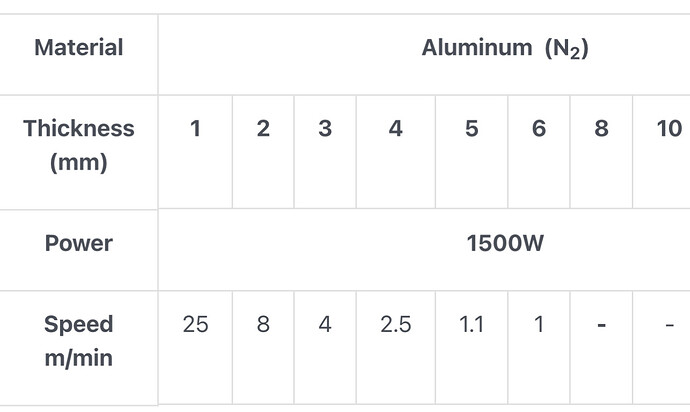

3000w 1.8mm/min in 6mm aluminum lol.

There is always waterjet! Been around for a long time and probably find in auction! Or mpwj??

I damn sure don’t have the wallet for a fiber laser but I still really want to build a co2 laser

Ok wait what was the cutter on the ender. It was at one of the shows!!

EDM. Very precise but slow.

I know a guy, who has a machine, that if you replaced the spindle with a fiber head mount…

Just sayin’

Okay. Tablesaws are scary, but I have one and use it. I give it the respect it’s due, and so far it hasn’t bit me.

Lasers are scarier. Even a diode laser can give you a life-altering injury very quickly, and at a slight distance. CO2 and more powerful lasers are more extreme and quicker.

Water jets… No thanks. I am perfectly happy to leave those to the pros, and the thought of a DIY water jet is frankly terrifying. The sheer cutting power that high pressure water can exert, I don’t want to be in the same building.

Doing computer consulting, I saw a client’s water jet cutter where a coupling in the pressurized area burst, and the incidental spray cut through reinforced hoses, belts and aluminum extrusion before the water pressure dropped. The operator said it was near instant. I can only imagine what it would do to flesh and bone. Fortunately the commercial machine has adequate safeguarding to ensure no injuries, but those safeguards would be a large portion of the cost to DIY, and likely to get neglected or even omitted. So… terrifying. One of the demo videos showed what happens if you try bending the pipe after the point where the water restriction is. The hose might bend… but the water still goes straight. (Hence this is very close to where the cutting action takes place.)

Aside from that though the machines look really cool.

I could see myself building a CO2 laser, as I believe I could contain 100W or so reasonably safely. A fiber laser? Super cool, but probably no. A water cutter? Count me out.

Yabba Dabba DOOOO!!!

OK - What is acceptable error on this thing to still get workable parts? I’m checking my new printer (home built from kit.) The numbers look small to me, but I’m curious if there is a functional level below which it’s even worth tweaking?

The author says it’ll never be perfect. Any idea of a “generally good enough” for V1 machines?

(Not really expecting an answer from Ryan - just wanted to reference his suggestion for the calilantern.) Any of the other experts have an opinion?

It seems like it is pretty easy to get under a tenth of a degree. If your printer is off several degrees you might need to run it twice but basically run it once apply the skew corrections and that should be fantastic.

A crappy will print the parts and they will fit together plenty fine to work. But we have tools like this so I am starting to design to a higher fitment standard.

You can also post up a screen shot of your excel sheet and we can look and see if you need tweaking or not. But I would say if you ran the print at minimum I would put in what it says. Usually unless it was REAL close I will print another and verify everything is good.