I can absolutely understand that the price tag isn’t that nice, for me it’s not that bad living in the EU, though you get one of the most advanced printers and you help a company develop that isn’t Chinese (please don’t try to misunderstand me on this one).

I just ponied up for a P1S but without the AMS.

I have an ender 3 I’ve upgraded various parts of, but printing all the Primo parts at a quality I deemed sufficient took forever, I didn’t want to repeat that!

Given that I want to print parts for prototyping and to help organize parts and tools, I don’t really understand the appeal of multi-color prints and all the wasted filament spent clearing the hotend. I guess it would be convenient if you switch materials often.

For those that want to print for less utilitarian purposes I totally get it, but the appeal is lost on me. At $599 I got an enclosed printer (can go in the garage now!) with a sufficient build size that should deliver high quality and print very fast. I think that price point (and that of the A1 without AMS) are going to be really hard to beat for anyone but the purist who is concerned about using proprietary software and not being able to easily tear down and modify their machine.

For someone concerned about preserving the capability to modify/learn from/ share the software, this isn’t a purity thing, it’s an essential requirement.

Everyone has their own priorities, and I understand your pragmatism. I just don’t necessarily agree.

Maybe I shouldn’t have used the word purist - I didn’t mean to invoke anything in particular.

As a former software developer, I understand the benefits of open source. We’ve all benefitted enormously from the truly selfless efforts of other engineers.

As a current designer, I understand the benefits (particularly to user/customer experience) of producing a closed system that tightly integrates hardware and software.

One seeks to maximize flexibility. The other seeks to maximize usability. These are always the trade-offs in the design of any system.

Ramblings aside, I think the 3D printer market has a range of options along the flexibility-usability spectrum, and that strikes me as a very good thing. Thankfully the ethos of the entire space is one of open-sourcing and collaboration. This community is a testament to that spirit ![]()

Guys. I have a genius solution to all of my problems.

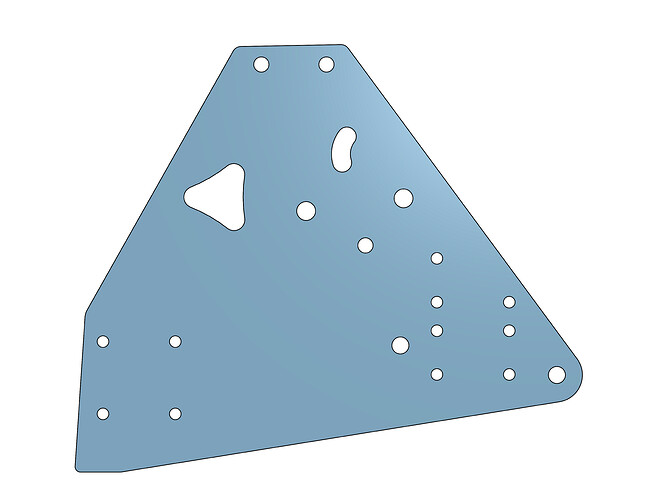

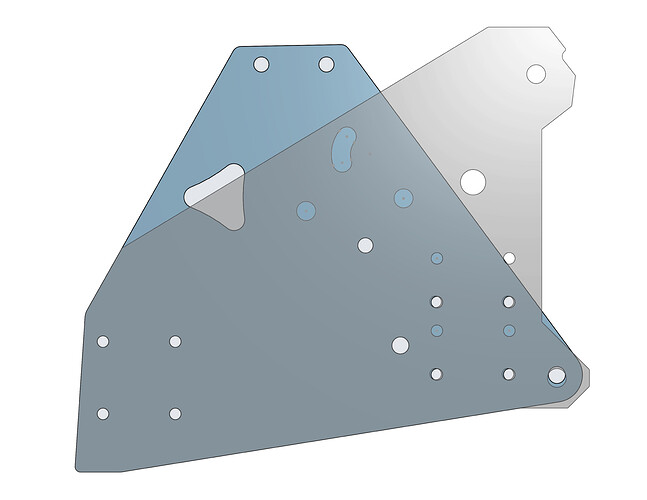

A ZX plate that is a superset of the most relevant features of LR3 and LR4 plates.

It won’t be confusing to anyone and we can start our LR4 Builds fast.

Interesting idea, except LR4 Release candidate 3 XZ plates are now yet again notably different, and they have slightly different hole/cutout features for +x/-x sides of the plates.

Just send me the updated version and I’ll make it work ![]()

If you don´t mind to see Bamboo everything what you do - go ahead.

I understand that a lot of people look only at the price - but i payed a lot to learn that the best price doesn´t mean that you will pay less at the end. My MK3 printed around 18k hours - with no! maintenance. The only thing i did was changing the nozzle 2 times.

And my 2 MK4 are also “click an forget” printers.

So I payed some money to save time, that i can spend with my kids, and that is priceless.

So I know the actual design is still up in the air, but I’m playing with an idea for the plates. Is there a set thickness or are they varying a bit?

Which “plates” are you talking about?

If you are referring to XZ plates, they can be either printed or milled from aluminum, and the design intention is for 1/4" thick. Some aluminum sold as “1/4” is only “nominal” 1/4" — I bought some and its actual thickness was 6.1 mm instead of 6.35. But in the end that small difference, made no functional difference.

EDIT: LR4 not officially released, so take with grain of salt.

Careful…

Right. I added a disclaimer.

The LR4 XZ plates do not have a printed option.

What he said! ![]()

I stand corrected.

I’m not printing, but I’m playing ![]()

A few notes…

-

It is not necessary to connect a Bambu printer to the internet. You can configure it to run in LAN mode. You can also use an SD card.

-

One printer is not more reliable than another. I don’t think anyone can make that claim currently.

-

One company ships their printers assembled by default without upcharging (a frankly ludicrous amount +37.5%?!?), which is a concrete and immediate time savings, and reduces the probability of maintenance issues caused by user error during assembly.

-

If the goal is to support an open ecosystem, why not extol the virtues of the MP3DP or Voron instead? We’re not even comparing the same motion systems here (CoreXY vs. Bedslinger).

Because building an MP3DP is much more complicated than building an MK4. I bought the Mini preassembled a few years ago (there wasn’t a kit) and I wasn’t happy with it because I wanted to know exactly how it worked. With the MK4 kit I now every screw and every cable and it prints fantastically without me putting a lot of time into tuning. The MP3DP needs extensive configuration before it prints that well (it might be the better printer, but it’s a lot of work for anyone not really knowledgable).

How is the LR4 coming along?

Currently the team is working on Release Candidate 3 builds.

Machine will be a great machine, just have some small stuff to refine a bit and test a bit more.