Hey does this cutting board look like Maple?

looks like poplar to me… what is it?

Thanks. I have a bunch of random pieces and scraps of wood/hardwood in my stash with no labels regarding species, and I’m not experienced in discerning which is which.

I don’t know! LOL

maple I’m most familiar with is very light and not two tone, though the grain structure looks similar to maple that I have observed. Keep in mind I am no wood expert.

I think I had some Maple, which I used for making a lifetime achievement award for someone. Not sure if I have any more. Who knows what all is in this pile.

I know a guy…

Is that Al or the guy from this old house?

I think I have a couple pieces of walnut and a few pieces of oak.

Have you ever seen both of them in a room together at the same time?? ![]()

Edit: If that picture isn’t familiar to you… here’s the reference…

It looks like poplar to me too. Poplar can sometimes have a purplish hue. The cutting board especially looks like poplar to me.

The heart box was cut from the same, but has had stain applied. ![]()

I would bet that’s poplar. It is very commonly two-tone with one of the tones having a notable green tint. I don’t know of any other species that has such a green tint.

And polar is 1/3 as dense as maple (Brinell hardness). That’s why I said two very different books.

I’d pull the video, correct the information, because the “facts” are very misleading and then re-release it when Ryan says it’s okay to go again.

Sounds like a plan.

There is some bit of confusion. As far as I can tell, the wood in the video in focus was apparently neither Poplar nor Maple. My best understanding is that it was probably Alder. However, its density is only moderately better than Poplar, and so still does not compare well with the Maple family.

I will pull the video and seek to correct it for later.

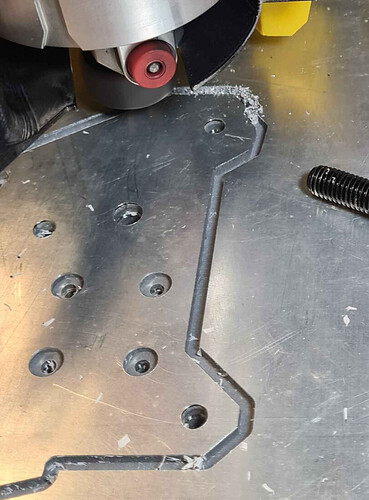

There is talk about printing LR4 ZX plates and then bootstrapping to alumunum. I may have an alternative? I just epoxied two sheets of acm together, to make an8mm sheet with double alumunum in the middle. It machines like the alumunum isn’t there(except for drill operations through the 2 adjacent layers in the middle) and is so friggin tough, will probably maybe do the job as well as alumunum plate would. I just made these for a couple of friends who are about to build. (But they are open to testing LR4, if you want me to recut the plates and send them the version for testing)

The only downside is as the cut gets deeper, the swarf from alumunum gets worked into the plastic component and makes the finish a little ugly.

You can see as it goes for the second pass in this picture, it all gets chewed up in there.

This may be happening because that’s a nub of a endmill that I broke with a wrench while tightening bu then just put the snapped off bit in the router cause the whole cutting edge was still intact.

What did you adhere the two layers with?

They modeled Al off Norm.

5 minute epoxy. Slower epoxy would have been better but thats what i had on hand.

Interesting idea, I’m curious to see how it performs!

I work with ACM pretty often. I actually saved a piece from a previous project to hopefully use it as the strut plate for the LR4.

Here in the Netherlands (and i think most of Europe) it is often named Dibond or Alupanel. It used to be hard to source but it is getting more commonly used.

The only downside I see to using this material is that when you overtighten a bolt or screw and it goes through the aluminium toplayer, the composite layer in between is soft. And that most of the times results in the screw not having a lot of holding power.

Also in my experience small sheets of ACM are not very cost effective, and I think the cost of aluminium plates would be close to the same as the ACM with epoxy glue.

But indeed the ACM is one of the easiest materials to work with, often even easier then wood. It is a bit messy however.

Let us know how it works out! :))