So, a long time ago, in a galaxy far far away…

I have been a long time lurker (joined in Nov 2021) here in the forum (and have spoken up a bit in some topics that I do have a little bit of knowledge on). I have a MaslowCNC, a BobsCNC Evo5, an Ender 3, and an Ender 3MAX. Because of this forum, I also have one of the $79 Cenoz JL1 Laser engravers. SO needless to say, I have plenty of “toys” um…tools to keep me busy. I started here with looking at the MPCNC. The Primo was just being released (IIRC) and was just looking and reading (and trying to scrounge up the $$) to go all in. I had also looked at the LR2, but at the time, I was really looking at the MPCNC. Since then, the LR3 came out, and ultimately looking at what I was going to be using it for, I decided the LR3 was more suited for what I would be doing: larger epoxy inlays, flattening slabs, and other things of that nature.

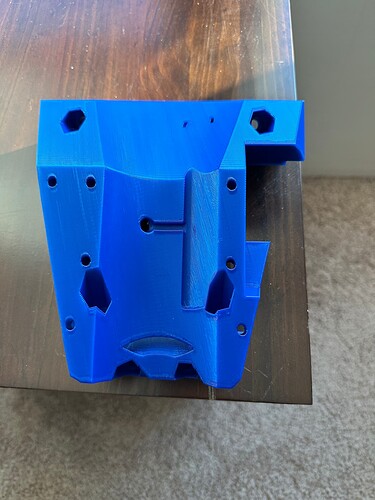

And so I come to you today to state I have begun my LR3 build journey. Last night I printed the core (12 hours, 34 mins), and I currently have a few pieces on the MAX printing (roughly 21 hours according to Cura - it said the core would be 15 hours, so we’ll see). I plan to cut the YZ plates in 1/2" MDF, and will be ordering everything else from V1 in the next week or so, as long as there is nothing that pops up on me that takes away from my play fund! Until then, I’ll continue to print parts. Initial thoughts would be for a full sheet build, but thinking I might parse that down to a 4x4 build. I want to redo my table saw outfeed table, and thinking if this might be good to just incorporate it all together. I like the tables @vicious1 and I believe @DougJoseph worked on. I can use the Maslow and Bob’s to get everything started, but I think I will have a bit of time to figure that out.

Until then, here is the core I printed. If anyone sees any issues, please let me know. I think I have enough filament to reprint if need be.

Edit: added a better picture that was a bit more in focus!