I’ve read through a few posts similar but nothing related just to jogging with the WebUI that I could find. I’m just wondering if or how I can adjust the jog speed defaults in FluidNC. I was using G00 while squaring the LR32 and the thing moved hella fast. I don’t need to move THAT fast when just jogging but it would be nice to be a little bit faster. I assume that is adjusted in the configs? Can someone point me to the setting to change and maybe tell me how to determine the speed G00 uses so I can find something maybe in between that speed and what it’s currently set at?

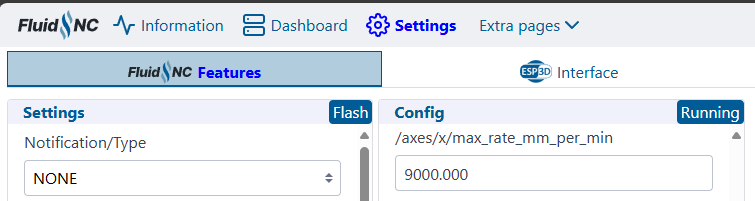

G00 speed is based off the max_rate_mm_per_min for each axis in the config.yaml. Or you can see it in the WebUI (I believe you are using WebUI v3) under Settings → FluidNC Features → Config. It looks like the defaults are 9000 mm/min for X and Y.

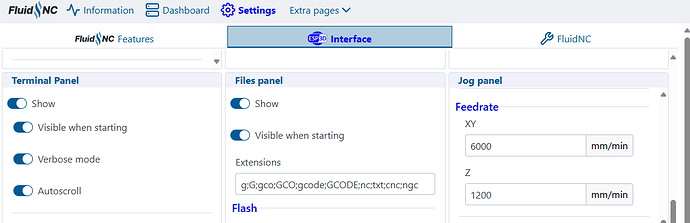

For jogging speed with the WebUI, you can see that under Settings → ESP3D Interface → Jog Panel. You have to scroll down in the Jog Panel to get to the Feedrate section.

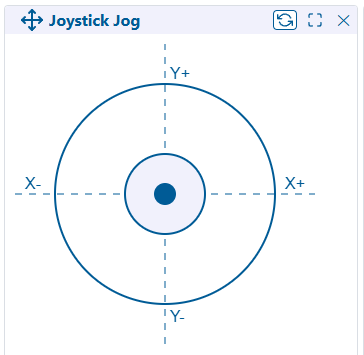

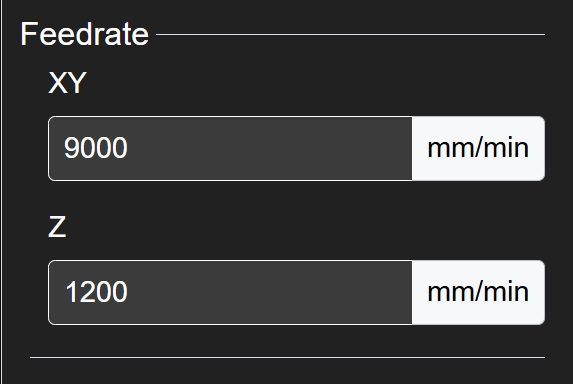

Those are my current settings which is faster than the defaults. My XY value might a little aggressive. My custom joystick jog panel uses those same values, but with a variable feedrate depending on distance of the “joystick” from the center.

XY is fine, I use 8000. ![]()

I didn’t realize this was a competition. ![]()

I had my pen plotter at 15000 XY for a bit. That didn’t sound good but 12000 is fine.

Everything is a competition… ![]()

Z 1200? Mine is 2000… ![]()

My laser cutter at 40,000 mm/min on XY makes me giggle. It sounds super cool.

What kind of laser cutter is that? Tell me it’s not a diode??

It actually is. Mostly used for cutting fabric at 5,000 to 10,000 mm/min. The high speed rapids make 20’ travels less painful to wait for.

Holy crap! What size diode? A lightweight one I’m assuming?

20 watt Sculpfun diode laser with air assist on an 8’ wide by 20’ long ‘perforated’ (85% open) table. 4" of Z travel for out of focus marking, or cutting/marking thicker materials.

If sales of the fabric things go well the next table will be 50-60’ long, or we’ll just buy a conveyor table… I’m not sure that I want to spend the time figuring out a g-code processor for one; perhaps there’s one out there already.

Amazing!

I’m sure it would be fun to see that in action!