I’ve decided to channel my anticipation for the LR4 into a build log. I have a well equipped but small woodworking/metalworking shop. The space is about 10’x20’ and I have the same number and type of tools I usually see in a shop twice that size online. I’ve just completed a new welding/outfeed table that finally gives me a dedicated place to store my metal cutting bandsaw and welder. So having finished that projects and being able to actually put all my tools away without having something sitting out I’ve decided not to actually get back to building furniture but instead to gut half my shop to make room for a cnc machine.

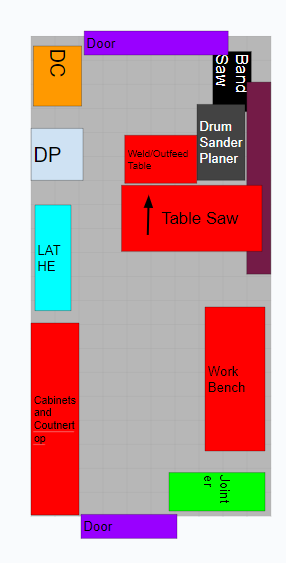

Before

Here’s a drawing of my current shop layout. The grid is one foot square.

The layout works pretty well. I definitely have to play tetris when I want to use the jointer or planer on anything longer than a couple feet but that’s fine in a shop my size. I’ve found that the countertop space on the right just collects junk and is rarely useful. I’ve decided to tear out most of it and the lower cabinets in order to make room for a cnc machine. I’ll be leaving a small 2’x2’ section because my 3d printer is happily housed in the cabinet below and it can be my dedicated electronics surface.

Here’s a photo taken from a few steps past the door at the bottom of the drawing.

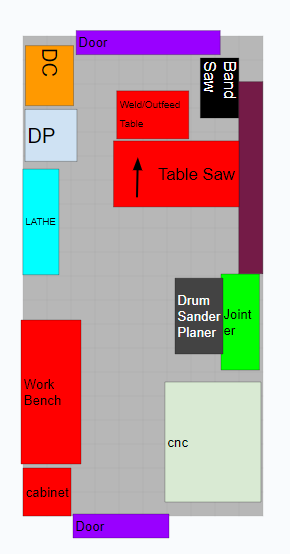

The Plan

I’m currently planning to build an LR4 with a usable area of 3’x, 4’y. I’m waffling quite a bit and debating this. The largest project I anticipate doing is some kitchen cabinets and I would be able to fit two sides in that space. But I’m debating making the x gantry 4’ so that I could more easily expand the y to 8 feet and do a full sheet of plywood if I wanted to in the future. I’d probably prefer the stiffness of a 3’x over the larger volume. I’d be glad for any input anyone has on sizing.

Here’s a diagram of the changes I plan to make.

I’ve already torn out the countertop/cabinet and moved my tools to their new spaces and left the things that had been stored in the cabinets where the cnc will live since they will have to be stored under the table. And all in all I think I like the layout better than what I had before.

If you want to get rid of your drum sander, just give me a shout. ![]()

Do you have some kind of cover for the weld/outfeed table. I would be concerned about particle contamination on any wood that goes over it.

I feel you on the small space. I had to give all my tools to my son 2 hours away so I could even use them anymore!

Yeah, I built it to be 3/4" shorter than the table saw so it’s flush when I put a piece of mdf on it. To weld I take that off and roll it out the doors.

I mean once I have a cnc machine I won’t need the rest of the right? ![]()

You’re doing way better management of your space than I am. ![]()

I have a 10’x16’ shop in a shed out back. My CNC lives in the garage ![]()

Man, you guys make every post with sizes a math homework… -_-

I’m a fan of doing this…

The original version of that site was better but I think google got it shut down.

Sorry. I prefer meters when doing math, but I can’t see the difference in my head between 3.3m and 4.9m. It is just what I am used to. There’s no logical defense, just an emotional one.

When I open up chrome on my computer there are automatically 3 tabs that open. The forum is the first one. My email. And then Google to a mm to inches calculator lol. It’s a ton easier designing and running the machine in metric. But like you I just can’t see it. I even have a Milwaukee tape measure that’s metric on one edge of the tape and inches on the other lol

You can’t see it because it is a concept duh… ![]()

The only one I can visualize (yeah, those pesky teachers… Like, can you go to the bathroom? Lolol never has this joke been made before…) are feet. That makes sense kind of. But I don’t like feet, do I try to stay clear of them. ![]()

![]()

is that a tarantula? have not seen one since I was in the mojave desert with the army! glad I live in michigan for that part!

My first thought was that it was a small tarantula since I live in southern Arizona. But I think it’s a wolf spider. After two days he moved back behind something so I haven’t seen him for a while.

Now that I have all my materials ordered I need to finalize the size of my build. In general a 2’x4’ machine would be big enough for the projects I have planned. But in 1-2 years I plan to redo my kitchen and will use the machine to build the cabinets. At that time I think I will set my machine up to temporarily be 4’x8’. What I’m debating is if I should make my X axis 2’ for now and rebuild to 4’ when the time comes or if I should just make my gantry 4’ now.

Can anyone weigh in on that? I know that a 2’ gantry would be much more rigid and really would be big enough for what I do most of the time. What sort of time commitment does it take to tear down and rebuild the gantry?

It takes new strut plates, new rails, a few more braces.

I opted for 1220X and 900Y because I wanted to have the option to have a longer table. You can see that I also did teeny tiny inlays on earrings with it, so it works pretty well, I‘d say. ![]()

Thanks Philip, that’s exactly what I needed to hear!