Well, I don’t know how that happened… Wtf. There’s nothing where it could have caught…

The overhang of that upper bolt hole.

Should be fine though. If the part fans are on full blast might want to look at extrusion temp a little closer.

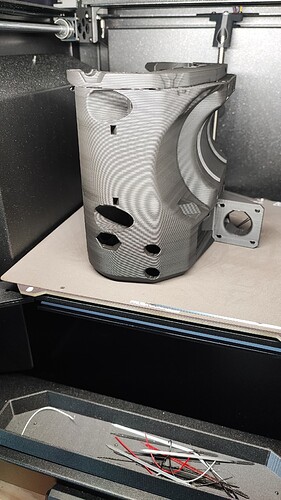

Oh yeah, interesting. Prusa changed their strategy of printing to reduce the visual artifacts, so the outer layer is always printed at max speed to ensure that it always looks good. Might lead to warping. Good catch, thanks. Will see how that goes this time. ![]()

What?

No, this wouldn’t be fine.

My TAZ likes to layer shift at that height. It’s got something to do with the upper bolt hole.

I’m hoping when I flip the extruder over to an H2 it will stop misbehaving.

So you had that problem before as well? Interesting.

Should print fine.

It failed at the exact same spot, it was definitely not the Core’s fault but looks like a slicing error. F…

100% the same shift, that was not a collision… I should have listened to my gut and sliced it again… ![]()

That is wild, does it show up in the preview in a different slicer?

Had me thinking I print those cores on 3 different machines, it really should not be a super difficult spot, but maybe? You printed the lower one fine a few times so it must be the slicer.

skill issue ![]()

I was stupid enough to delete the file from the printer before reslicing and uploading, so I’ll never know. I basically thought about the possiblility to view it in another viewer five minutes after deleting it…

These were also the first two tries after having sliced them after the new update of the Slicer, so it was a completely new file that might have been messed up. I had this happen once before.

I had that problem. at the time I was using PrusaSlicer for the TAZ, lately it’s been Orca…

Good instincts.

Bummer.

really weird that I’ve had problems in the same exact spot.

But there’s almost no change in the STRUCTURAL setting …?

You are right there, that‘s why they introduced the balanced profile. Had to read it again. ![]()

I just re-sliced it again, this time I moved it around on the printbed. I can pinpoint the layer when it happens, it’s one layer before it’s supposed to print the bridging over the hole. Still, there is no binding or anything, the last time I caught it directly after it happened, this time I am going to film it (if I don’t miss it…).

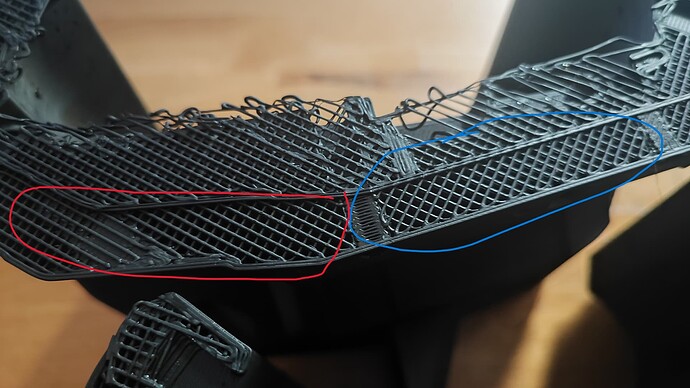

For all three it has completed the infill for the bottom part (blue), but fails on the infill for the top part (red). So it fails doing infill. I really don’t get it.

did it fail on the infill? In the sliced gcode, is there an error and shift in there?

I had originally thought on the TAZ that the nozzle was dragging on something and causing a shift.

Now I’m not sure if perhaps it isn’t some weird bug in PrusaSlicer.

It’s not dragging on anything, the file looks fine. Regrettably there aren’t other gcode viewers that read bgcode and Notepad does not want to open it because it’s so large.

I have the theory that it fails at a certain height, but that means a) printing another core (which I am doing at the moment) or b) printing another large object and see whether that happens as well.

So two theories: mechanical problem or Slicer bug.

It’s pretty weird, have you printed things of this height before on this machine? Is it something a simple tall tower can reproduce or is it just this model?

I’m wondering if there’s a jump in one of the Z screws, a burr or just enough of a catch to throw off the layer. Have you lubed 'em? Curiously the early instructions had detailed instructions to do that including a printed gadget, but they’ve disappeared. Presumably that was a cut an paste from the XL that wasn’t picked up - the current maintenance knowledge base doesn’t mention anything.

So many questions! Tomorrow I have to dismantle the print head and Nextruder to start the INDX install bearing repair. I’m hoping the balls are actually 2.5mm because that’s what I’ve bought - but I have one of those legendary vibrations that everyone says is bearings but isn’t, so I’ll be tuning every screw to make sure I haven’t missed one, then giving everything a gentle dose of ptfe spray lube.

I’m pretty sure I don’t have any print issues!