Hey all,

After reading about @Fabien’s challenges to correct for non-perpendicular core (LR3 traming - X and Y direction), I decided to check my printer for skew before attempting to print the core for my upcoming build.

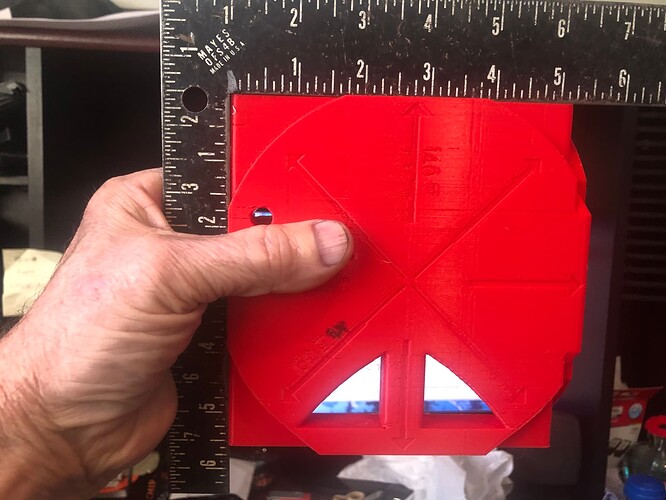

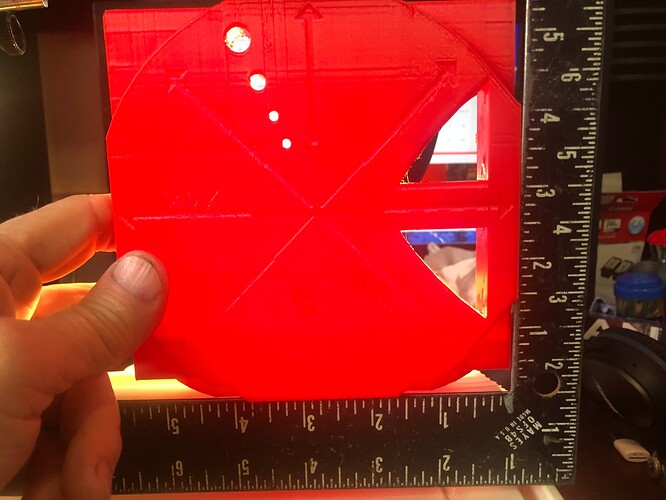

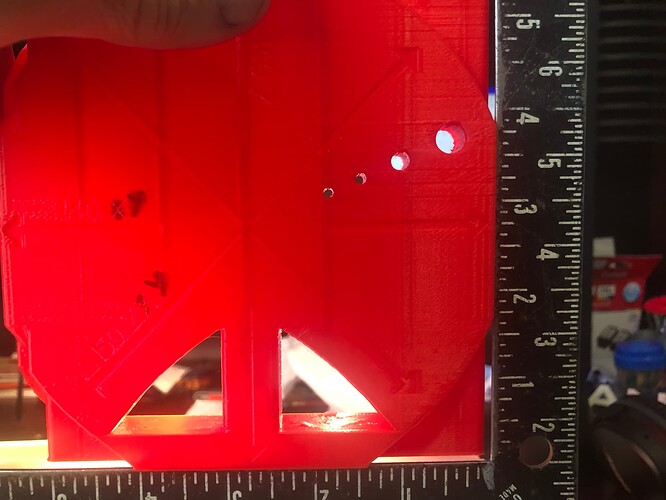

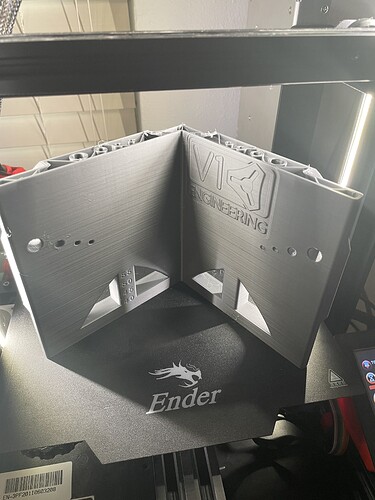

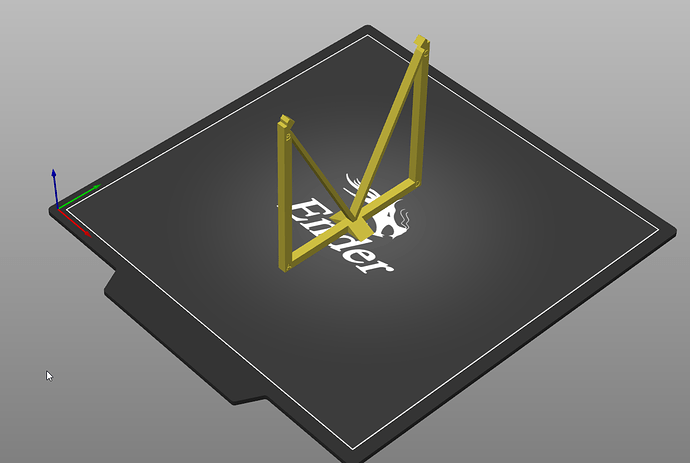

I printed Ryan’s (@vicious1) xzyz-test file from Printables (15.4 hours, almost 150g of filament at 5% grid infill). I did have to rotate the print to avoid one area of the bed that was having some adhesion issues (warped glass bed?), so the X and Y labels were swapped, in case anyone notices that.

I’m not sure exactly how to interpret the results.

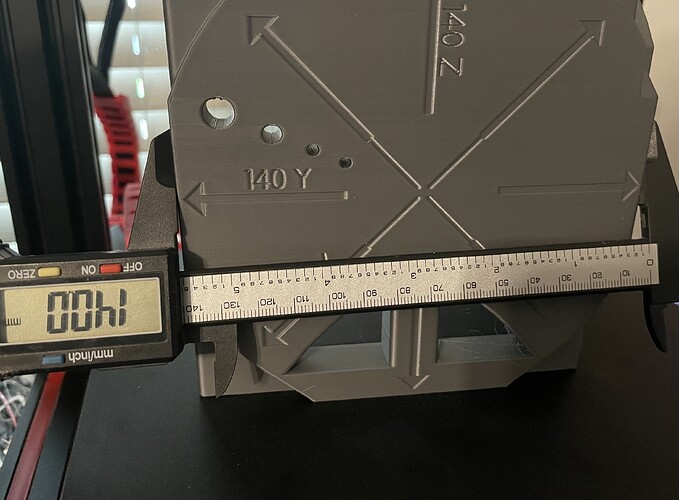

X horiz = 140.89

X vert = 139.85

X \ = 150.10

X / = 150.63

Y horiz = 139.88

Y vert = 139.89

Y \ = 149.56

Y / = 150.20

Using a square, I get pretty close to perfect on the XY and XZ section

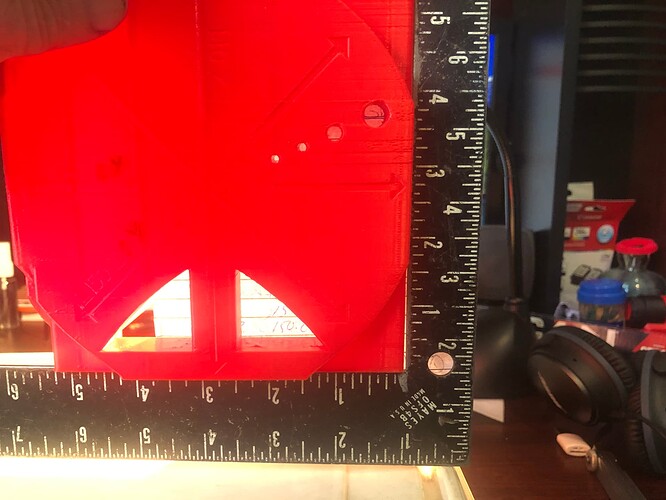

When measuring YZ using the bottom layer, I get a bit of visible gap

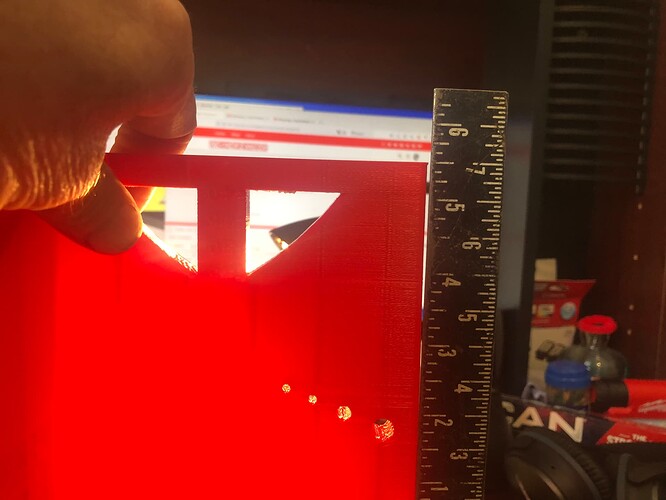

When measuring YZ using the top layer I get a much more noticeable gap,

but when taking the same measurement using just the top of the thickest section (rather than the entire length of the narrow section), the results seem much better

I have tightened up all of the screws on the printer prior to printing this piece. and don’t see any obvious bent or misaligned parts.

So I have two questions:

-

Are these results good enough that I can print the core as is? ( I hope so, because the next question opens up a can of worms…)

-

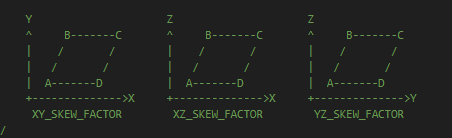

If I do need to make adjustments using the Marlin Bed Skew Compensation (may require re-flashing the printer in order to enable BSC), how do I apply these results to the Marlin Bed Skew Compensation formula?

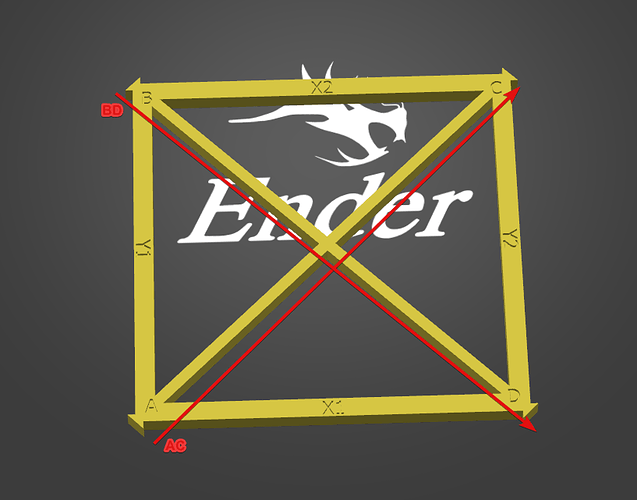

Marlin configuration seems to be based on a test print that is 100x100, resulting in an expected measurement of 141.421356 mm (doubled to 282.842712 mm), so presumably I could scale these values of the 150 expected test print value (measured value x 141.421…/150 = new Marlin value).

But I am uncertain which points on the test print correspond to AC and BD on the Y axis. Note that the print was oriented so that X axis section was at the back (or Y min) of the bed, and Y axis section was at the left (X min) of the bed. So in Marlin , is the bottom rear to top front AC, or is the top rear to bottom front AC?

Just a note that the LR3 will probably be used mostly for cutting 3’4" plywood, 1/4" aluminum, and possibly carving wood/plywood for signs and decorative items, so I’m not sure how much time and effort I should expend to chase exact square/perpendicular, and if compensating with shims between the core and router might be a better way to skin this particular cat.

Most of the discussion about square/perpendicular seems to come up during surfacing, so if I keep any surfacing tools small diameter, maybe I can live with this imperfection?

Any advice is much appreciated, as always.