How many posts before i told you to remeasure your bits? Not all are the same spec

How much more measuring do you want me to do?

If you’re suggesting to me that every person who uses a CNC has to meticulously measure and re-measure every single bit they use because the manufacturer can’t be trusted to make them to spec, I’m calling BS.

I’m looking to get close enough that I can machine two parts that fit together like they should. I might be close (or close enough) to that goal at this point; I haven’t had time yet to do enough testing to know for sure.

I still wonder about what your chips look like. Dust rubbing on soft material could certainly rub more off. Something is making your slot larger. Some possiblitles are:

-

Measurement precision… hard to achieve in soft materials.

-

Suboptimal material removal rate (chip loading) or using down cut endmills with nowhere for the chips to go.

-

Suboptimal CAM… endmill dimensions don’t match CAM (expensive tool pieces should be fairly on spec, cheaper ones not so much).

-

Microstepping not holding position. Full steps with a 16 x 2mm tooth sprocket and a 200 full step per revolution stepper gives you 0.0063" full steps. I suppose you could turn the driver current up to see if it goes away.

Also don’t forget that with your Y-axis moving 999.5mm when commanded 1000.0mm, you’ll see 0.001" less movement than commanded for your 2" test piece. You should tension that belt to match the other Y belt.

FWIW, in my manufacturing experience, default tolerances are typically +/- 0.005" for metals and much more generous for organic or softer materials. It seems like you’re in the neighbourhood. Press board isn’t really ideal for tight tolerances.

So you ended up changing your bit/bit supplier and got accurate measuring? Is that bs? Have fun

FWIW, I didn’t do any real measuring like you have when I put my test table together. I pushed the pieces together to make sure they fit. Some of them were a bit tighter than others during final assembly.

Yeah, but remember this thread started out being about cut differences between the left and right edge of my table.

(And, having previously built a similar table that I cut on the table saw, I know that a tight fit with MDF can quickly turn into broken pieces as you try to force the fit…)

Out of town for the week (new grandbaby. Yay!) but hope to get back to more tweaking and testing when I’m home.

congratulations to you!!! enjoy the time together!!

It’s been a while (new grandbabies are fun!) but I’m back at it.

Wanted to post a summary of everything I’ve done up to this point and a “current status” of my efforts to get my LR4 to cut more accurately.

In no particular order:

- Replaced the belts with new one from the V1 shop. Tensioned them to what seems “reasonable”.

- Replaced the Makita router with a Carbide 3D router that comes with an ER11 collet

- Updated to the latest FluidNC firmware, restored the default configuration. Did not modify the run_amps or hold_amps (though I meant to bump them to 0.9 and 0.6 respectively - may try that shortly).

- Squared the machine again; diagonals now measure about 1mm difference on a full-sheet table.

- Lubed the Z axis and guide blocks with SuperLube.

- Re-checked Z axis level on all 4 corners of the table and adjusted as needed.

- Tightened the bearings on the core so that it moves without any wobbles in the x axis

- Tightened all screws on the gantry. Loosened the Z Stub so that it’s just barely holding in the nylock part of the nut.

- Tested with numerous bits, mostly by SpeTools. I did do a test with a new Kyocera 1/8" single-flute upcut bit but didn’t see any improvement of note.

- Tested cuts in MDF and baltic birch. No appreciable difference in results.

- Played with a range of feeds and speeds - finally landed on about 60 in/min for my 1/4" 2-flute upcut bit with .25" depth of cut and about 14000 rpm on the router. I really think I should be able to go a lot faster, but maybe that’s just a fantasy.

- Used both EstlCAM and VCarve to generate the G code

After all of these changes, however, I’m still getting cuts that are off by 0.03" or so, which is enough to affect the fit for parts that are meant to go together - like the torsion table that started this whole thread.

If there’s anything else left to try, I’m all ears. About the only thing I can think of that I haven’t tried yet is re-calibrating steps_per_mm, but I’ve been told that’s not supposed to be necessary.

So translated to mm that’s

25mm/s with a 6mm DoC with a 2 flute 1/4 inch bit.

Yeah, no that’s not too slow.

If you want more performance on a full sheet machine you’re going to need to spend a few thousand more on something else I’m afraid.

You haven’t mentioned using a finishing pass, that’s highly recommended for dimensional accuracy.

Should have included that. I’ve been doing a 0.02" finishing pass at full depth for the last several dozen tests. Might help a little but not that I can really tell.

If there a reason you’re using a 1/4 bit?

I would guess it needs double the force of an 1/8 bit to push through material, being double the cutting face size. And a 2 flute bit will need more force than a single flute for the same diameter.

I don’t have a 1/8" bit with a 3/4" cutting length. The Kyocera bits have a plastic collar on them that limits depth to 5/8". I can take the collar off, I guess, but not sure about cutting beyond the flutes.

Nah, not really. I nearly only use 6mm 2-flutes and go up to 6mm deep at 2400-3000mm/min. The limiting factor is the LR, not the endmill. ![]()

It heavily depends on the wood though and on the accuracy I want to achieve. ![]()

Well that’s not good, it’s 50% worse, or so, than your previous deviation of 0.02".

You changed a lot of stuff at once… not sure what to suggest.

I suppose starting with confirming no-load positioning is accurate would be the place to re-start. You mentioned being off 1mm from square, but nothing about X and Y travel distances as you had before. I would be using a V-bit to poke some holes at the far extents of your machine travel and measuring them.

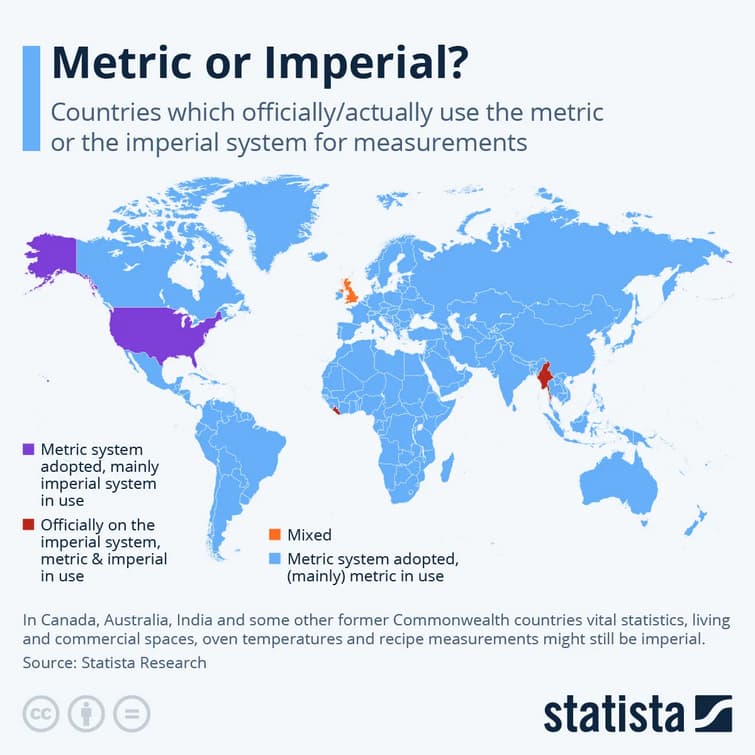

As an aside, it’d be great if everyone could stop bouncing all over the place with imperial and metric units and units of time in this thread. Heck, even consistency in units within each single post would be an improvement.

What did you see, though? Knowing what you got with the nominal 1/8" bit vs the nominal 1/4" bit could reveal something.

I can’t do imperial. If we were to use one system around here, it should be the one all of the world except freedom eagle country uses.

Re-checked just now, X axis is dead on at 1200mm and Y axis might be .5mm short over 2200mm. Don’t think I’m going fret those measurements.

In another thread I started today, I was reminded of the apparent necessity of lying to the CAM software and telling it your .25" bit isn’t really .25" – and I did another test just now using .231" as the bit diameter and got perfect cuts.

So, while I don’t like it, I guess I’ll just have to live with it – at this point, I really want to get the torsion table that started this whole thread cut out and built…

I’m still not sure I saw this measurement. I don’t care what size the bit is if that differs from the slot width it cuts. This is cutting wood with a router, these measurements may not be the same.

Re-checked just now, X axis is dead on at 1200mm and Y axis might be .5mm short over 2200mm. Don’t think I’m going fret those measurements.

Yea, so it’s not steps per mm. The machine is moving accurately. So, we’re in a bit/slot width and deflection space.

I can’t do imperial. If we were to use one system around here, it should be the one all of the world except freedom eagle country uses.

I’m in the “freedom eagle country”. I use imperial for normal everyday stuff because that’s what we see. For CAD/3D printing/CNC and science things, I stick with metric. CNC uses metric by default and is certainly most common on this forum. At least FluidNC defaults to G21 (mm) and putting it in G20 (inches) just means the code is converting inches to mm. Even if I design something in inches, I still use metric for CAM. The imperial system is stupid.

So, we’re in a bit/slot width and deflection space.

I guess bad runout would result in a wider slot than bit diameter, right? I’ve used a handheld router maybe twice before giving it to the CNC to hold so I’m a bit light on the understanding!