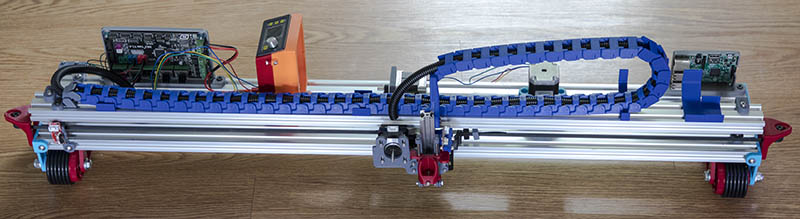

I took my plotter apart the other day and plan to do an assembly video just to do so. I picked up my new O-rings from Grainger, but they were the same as what I had. Either they sent me the wrong ones, or they were marked wrong on the website. I will call them & either return them or exchange them if they do indeed have 70A O-Rings.

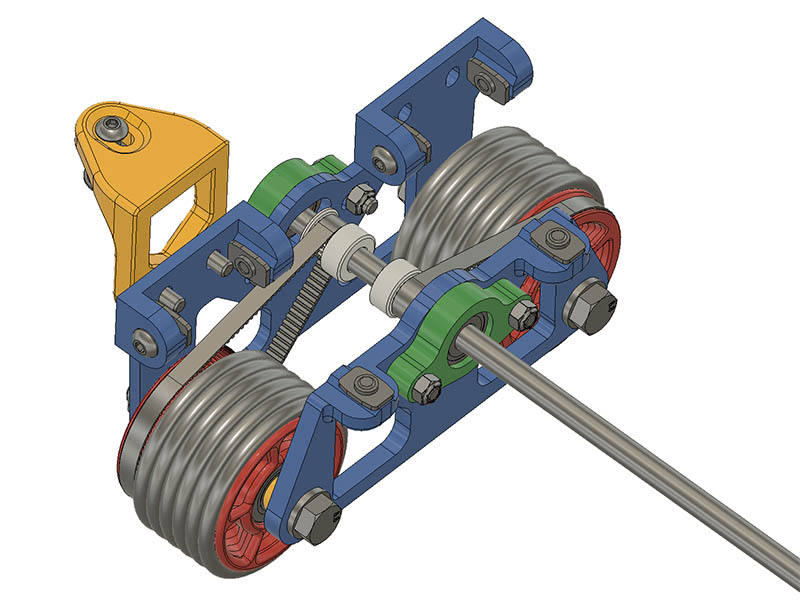

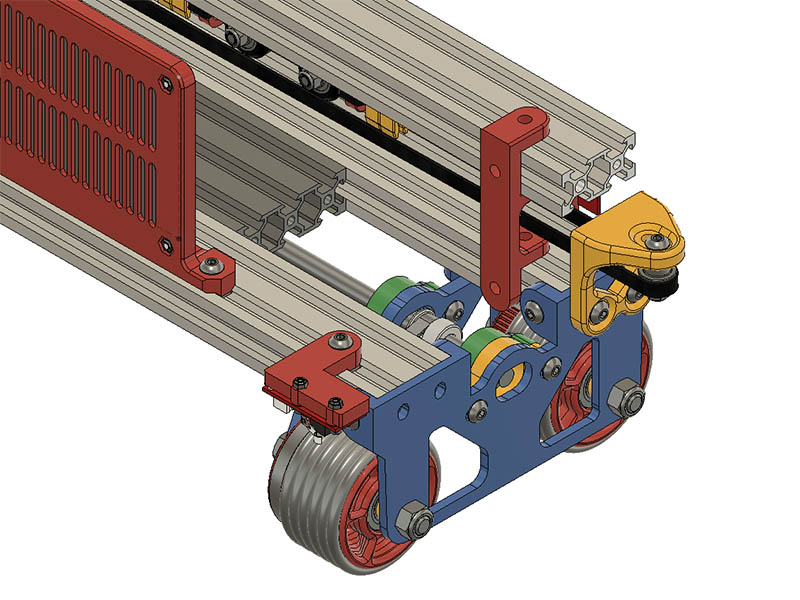

While I had the machine apart, I was thinking of another option to drive the wheels with AWD (All Wheel Drive). I don’t plan to test this but thought I would add it to the blog in case someone else wants to try it. If you look at the attached image while reading this, it will probably make more sense. What I was thinking is this machine could probably be changed a little more to drive both wheels on each side by putting the 80T wheel gear near back plate instead of the front plate for one of the wheels on each side. I don’t know if there is any advantage to doing this as my 1st design did drive both wheels on each side, but in a different way. The first problem is your M8 rod would have to be 22mm longer than the aluminum extrusion you use, since the bearing that was on the inside of the back plate would now need to go to the outside of that plate. The main assembly problem would be getting the 240T closed loop timing belts on each side since there would not be a way to adjust them easily. I think it could be done by having the wheels not bolted to plates 1st & tensioned them in place to tighten the belt. You would also need 2 more of the 240T belts & 2 more GT2 Timing Pulleys 20T bore 8mm. One of the spacers would also have to be a different thickness. After redrawing this, I did notice I had the back plate located 2mm too close as the wheel spacer on that side intruded into the back plate 2mm. That error doesn’t affect this assembly unless you create the AWD. 2020 hindsight, I should have had the bearings on both sides of the wheel the same offset from the most outside edge of wheel. Here is what that idea looks like.