Remind me again, in what way is it off? I assume if it rolls forward and back (multiple times) then it’s not quite where it started, but is it just displaced front/back or displaced side-to-side or rotated? Or some combination? And since you are talking about weight distribution, the error is inconsistent depending on the x-position of the pen carriage?

My current method of seeing whether it is off or not without getting the pen involved is to visually line up the edge extrusion with a line on the cutting board. I look to see how far askew the extrusion is when it is finished. It was not as far off with the wider tread, but still off some. Maybe I need to find a way to more accurately measure that. I didn’t get around to trying the C-Beam yesterday but should be able to today.

[Edit] It does seem like it is the same side that is skewed the same. Someone might have mentioned this before about adjusting the motor on one side a little differently. I do have the wheel motors on separate steppers, so I just adjust them different. I just finished cleaning the kitchen floor so I am ready to give it another test.

I tested the C-Beam version a bit yesterday and it was actually further off than using the 2040s. The wheel plates are a subassembly held on with 8 T-Nuts on each side, so that variable should be the same. From this info, seems like the extra weight made it worse. I didn’t think about it until after the testing & probably because I didn’t want to bother with adding the pen but drawing a 100mm line along the wheel track on the near end & far end should show the difference if it is adjustable by stepper distance. If I can find that pen mount around my room will see if I can test that sometime this weekend.

[Edit] I might also need to turn up the VREF on the TMC2208 drivers. The near wheel side is at 0.45v & the far side is at 0.47v. Does someone have a recommended voltage for this? I am thinking of going to .65v at least & retesting. Might not be able to test it until Monday.

[Edit] I pulled the driver chips off to verify the resistor size & dipswitch settings for the microstepping. They are actually Bigtreetech LV8729 chips capable of 1/128 stepping. I have them set to 1/32 with the board jumpers which I seem to now recall doing to match the DRV8825s that I had on prior to these. The VREF formula bigtreetech shows for these is I= Vref/(Rs*5), Rs=0.22Ohm, Imax=1.8A

| Vref | Amp |

|---|---|

| 0.45 | 0.41 |

| 0.65 | 0.59 |

| 0.75 | 0.68 |

| 0.85 | 0.77 |

| 0.95 | 0.86 |

| 1.1 | 1 |

In klipper config I have

microsteps: 16

rotation_distance: 23.8

Be to be consistent, I should change the microsteps to 32 & adjust the rotation_distance accordingly.

Changing the Vrefs did not help at all.

I started with .72v & .75v (It is hard for me to get them exact on both sides)

then 0.92v & 0.94v

and finally, 1.48v & 1.49v (The motors were quite warm at this setting after sitting a while)

I put this design away for a while & am considering going further down this rabbit hole using one motor for both sets of wheels with a connecting M8 smooth rod between them. I had been thinking about doing something like this for a while & after seeing this belted Z-axis design I could see how to do it. GitHub - kevinakasam/BeltDrivenEnder3: All parts including Voron files for the Belt Driven Ender 3 V3

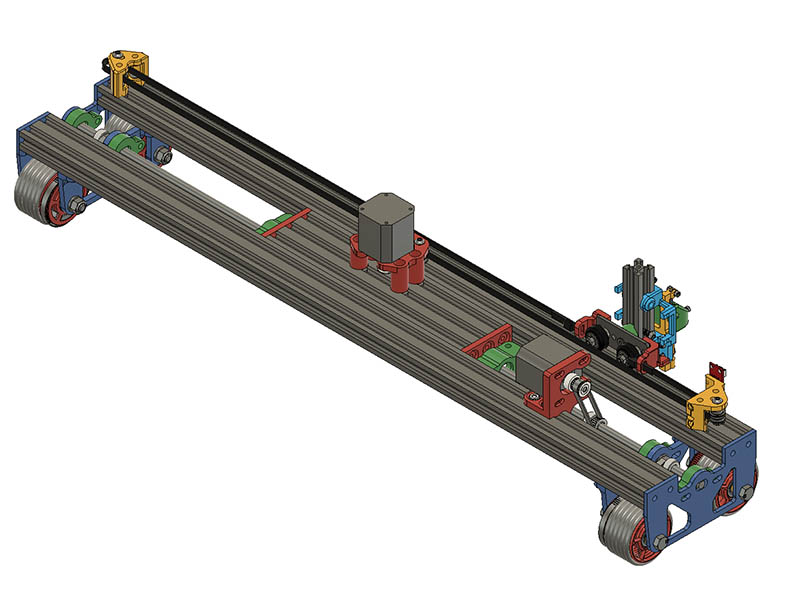

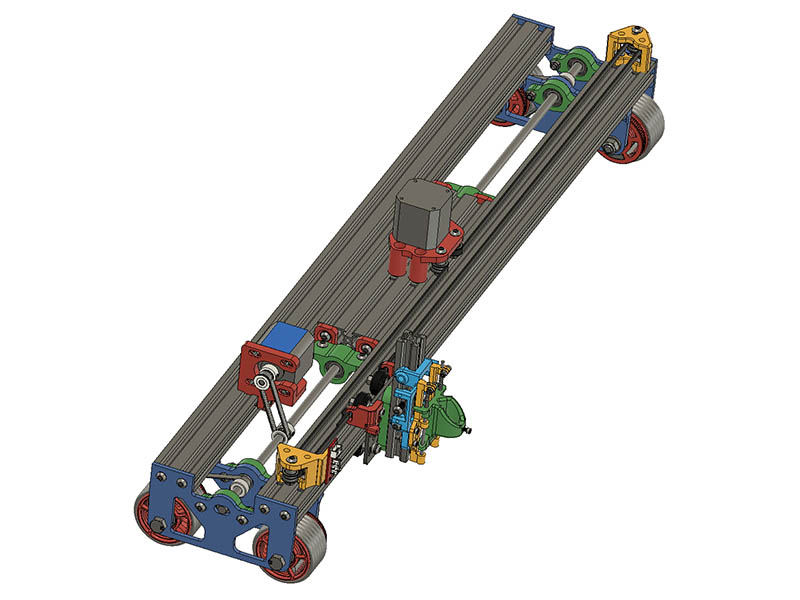

My biggest problem was being able to adjust the belt for the motor to M8 rod & also be able to adjust the belt between the M8 rod & wheels. Looks like this should work. I won’t have to reprint the wheels at least. I might have to adjust the offsets a little bit more. I am also going back to the O-ring wheels as those worked the best for me & since the wheels are supported on both sides now, I added as many as would fit (6 on each wheel). Here is what I have so far. The parts in green can slide 3mm each way & have skate bearing in each of them.

Think I have it adjusted for all the parts to fit. I had to order another closed loop timing belt. Shortest I have is 188 & it needed to be in 148-152mm range. 148 is what I calculated, but when I drew all the teeth in the belt, comes out closer to 152. I ordered 146, 148, 150 & 152mm lengths. One of those should fit. I had to change the wheel spacing from 110mm to 115mm for the wheel belt to fit. I changed the 2060 brackets to 2 parts on each side with a T-nut connecting to the 2040s underneath. Maybe I will have the new parts printed by the time the new belt comes in.

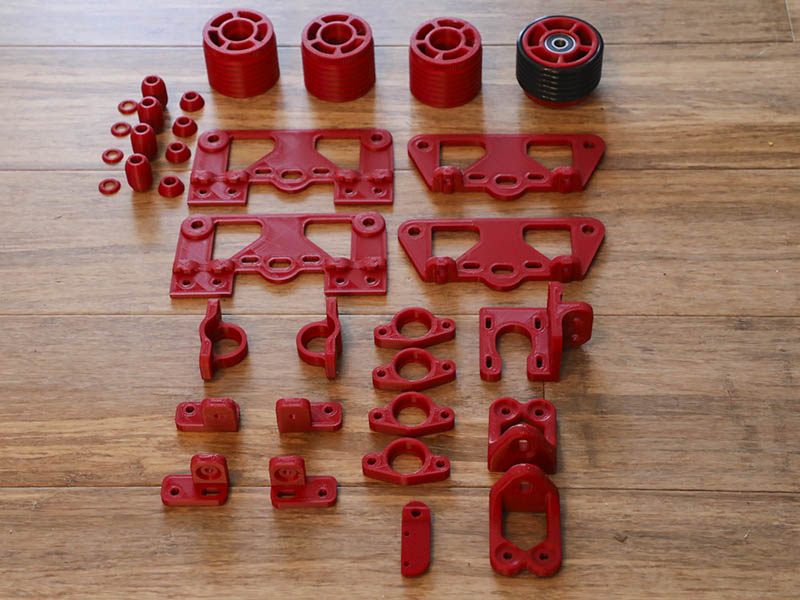

I finally have all the new parts printed & the hardware from China. Sometime soon, I should be able to put this new design together. The main thing I changed since the last assembly image shown was to cut out the outside bottom T-Nut connections on the 2 main plates. Looks like it should have enough support with the wheel bolt & the back plate that screws into the ends of the 2040. That should give me an extra 25mm width of travel which looks like 24" width with 800mm 2040s. I also changed the 2 top yellow idler pulley mounts to mount to the ends of the V-slots. I spent a few days last week tuning my printer to get more accurate prints & switched back to klipper firmware to mostly be able to use input shaper. That did make a difference. I am now mostly printing at 80mm/sec up from my 50-60mms. I see the latest version of Marlin is starting to use input shaping but will wait on that for a while. I did the manual input shaping & didn’t use the ADXL345 board. I am starting to think about playing with tire treads as an option replacement for the o-rings. I have done a coupld of those designs but looking for some other ideas. Anyone have some links to something like tire tread design?

This is just a search: Search Thingiverse - Thingiverse

Thanks. I had not done a tire tread search on thingiverse in a while. The ring_3.STL in that 1st link looks interesting to play around with.

No worries. I had because not too long ago I added micro swiss direct drive to my printer. So I have been looking at tpu for a while. It is a little pricey though, so holding back. Good Luck.

This is the 95A hardness TPU I use at $22.95 a roll. They run some discounts at different times of the year. Zyltech Filament - ZYLTECH Specialty Filament - Page 1 - ZYLtech Engineering, LLC

I do like the softer 85A hardness better from eSun, but is a little trickier to get started & also more expensive.

@geodave not sure if you’ve come across this already but this looks like a interesting option once you select a treat pattern.

Looks like they could have some good traction.

Thanks for that link. I knew someone on here would have come across something interesting that I have missed. That is an interesting tutorial. I was just thinking the other day about how to do molds for these & low and behold someone gave me the link for it. I can get better prints from plastic than with TPU, so this might be a better choice. I did reverse engineer one of the tires on the previous link, but now need to resize it to fit my tire. I always find it better to redo it the same size as what I am using as a template before resizing for my needs. I will play with previous design first before going down this rabbit hole as I don’t want to be too scatter brained.

Hahaha, so simple, that is insane!

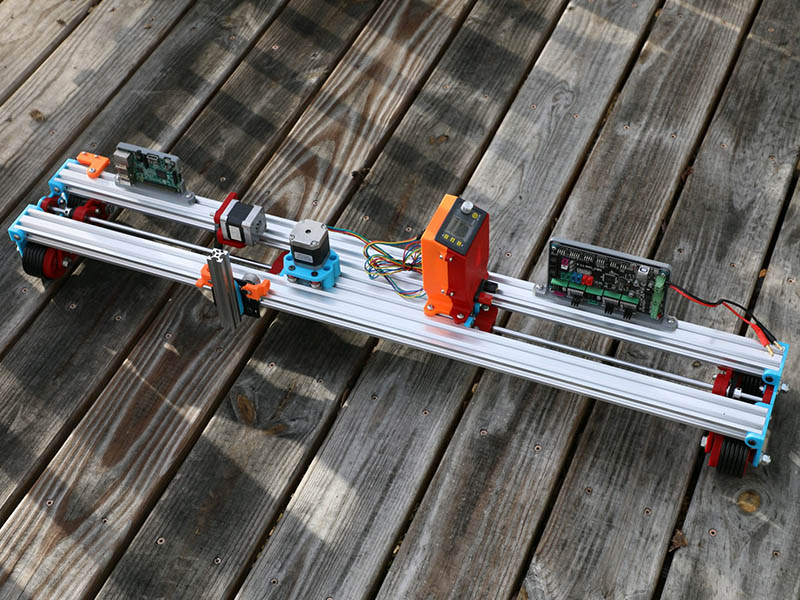

I am starting to assemble today. I am going to change wheel plates a little more to have bigger inner slot for bearing. It does not bind when tightened but seems like the slot should be a little bigger to keep it from possibly binding. I am connecting the back plate on the sides rather than using tapped hole which cuts down on the number of tapped holes. I did tap one of the 2040s on both sides to attach the idler mounts to the ends.

I also just noticed this interesting remix of my original rolling plotter that was done over a year ago also using one motor to drive both sets of wheels. He is driving both wheels on each side rather than just one wheel with some interesting linkage. https://www.thingiverse.com/thing:5147892 @dkj4linux might want to look at this one as he has a laser attached to it with a proper z-axis.

Can you bring it to RMRRF? https://rockymountainreprapfestival.com/

That is probably too far a drive for me from Western NC & I am not interested in flying there. I will keep that in mind if something changes between now and then. Thanks for the info.

Ship it out to him

You know have you looked for hobby shops rc truck tires?

I got this new version mostly assembled yesterday. Since I had to get a 1-meter long M8 smooth rod, I decided to go ahead and make the plotter 1-meter in width. The 1-meter rod is a little shy of 1-meter, so am making some 7mm width spacers to add between the back plate & outside bearing plates. That seemed to be the simplest way to do it. I thought getting that long m8 rod would be a problem getting lined up properly, but using a simple 3d printed shim 26mm wide while tightening each bearing position made it quite easy. I did have a little bit of forethought & put the wheel locknuts to the outside to make it easier to change the O-ring tires to TPU or replace the O-rings down the road. I also changing the F625 bearings to these bearings. https://www.aliexpress.us/item/2251832664674464.html They seem to be a better quality than the original ones I was using.