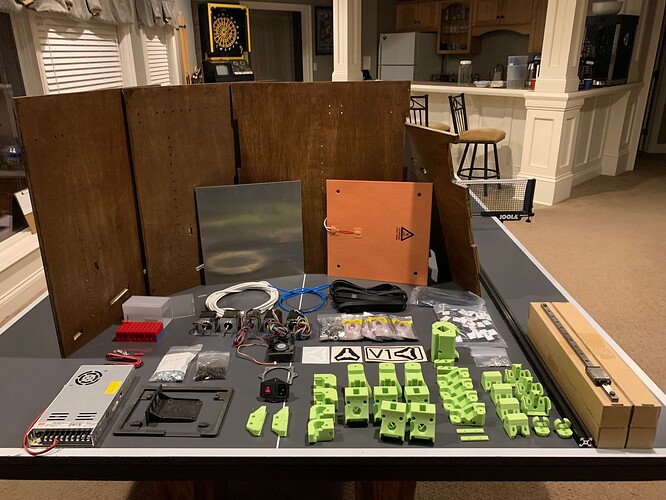

Well, I’m underway. Not going as smoothly as Matt’s recent build log, but I’m still pretty excited about how it is coming.

I started with a pre-build advice request:

While I was printing most of the parts, I started messing around with Fusion 360.

I started with making a couple of remixes of the “Hub” - first, one for a 19mm square tube which is readily available to me localy, and second, one for a 2020 V-Slot profile tube which I had on hand.

I will say that even though it has a little more drag, the V-Slot version seems to glides on the rail super smoothly and feels great. The penalty is weight - it is quite a bit heavier than 1/16" wall square tubing. Having both on hand now, I am not sure what I will end up going with, but I will post both regardless. I did end up resizing the “Truck Trigger” parts for 19mm square too, so that remix will be available as well.

I also added a few parts to the Fusion 360 CAD assembly as I sorted out how all the endstops worked and belts were routed. In the process, I re-ordered features, named many and tidied up things so I could understand everything. In the end, I broke some part parametric relationships to each other, so it’s probably not better than the one Ryan shared, but its now easier for me to change the things I wanted to play with - namely the size.

I settled on 5 350mm MGN20H rails for a build volume of approximately 300x300x300. This was a magic size for me because the frame came out with a footprint of just under 20" square. My Burly was sized to run a needle cutter on 20x30 foam board, and the frame pieces are a very tight fit, but should be producible.

Unfortunately, the first side I cut from 1/2 plywood is not square. It’s been a while since I checked - most things I make are cosmetic and the error is small enough to not be readily apparent, but probably not good enough for this. I’m sure I can get it sorted out, but it’ll be a bit more tinkering first.

I’m almost ready to pull the trigger on my V1 shop order, but I’ll probably wait until I get the frame cut and assembled. The costs are starting to add up, but I think it’s going to be well worth the upgrade when I get it done. I’m on the fence about painting it - I will likely seal it and leave the look natural.

Pictures coming soon…

)

)