Does anyone have a 3D print file for a Ridgid R24012 router mount for the LowRider V3. if so could you tell me where I can download it . I’m new to this site and I just finished 3D printing all my part to find out my router doesn’t fit . Any help would be greatly appreciated.

thanks

Dave Gethings

Welcome to the forum!!!

What is the diameter of your router? There are a few different tool holders for various makes (Dewalt Makita, some different diameter spindles, etc.). Knowing the size of your router can help to identify which one might fit.

if the rigid is a full-sized unit, you might be further ahead to find one of the closeout Kobalts on sale for $40 at Lowes.

Looking at the specs on line, it appears to be a trim router, similar in overall size to what most people here are using. 1.5 HP rating.

From the reviews it seems that the collet has some issues with slipping and not being able to tighten fully. Also the speed range is rated at 20000-30000, which may not give slow enough speeds for CNC purposes

If the OP has a Lowes with closeout prices on the Kobalt, that may not be a bad idea. However his existing router may work fine if we can figure out which mount to use.

From the pictures, it appears the problem is the slide part for Z stoppers. there seems to be a cylinder, which we could deal with easily enough, but then there is also a rectangular portion along the edge for Z adjustment. Some sort of provision would need to be made for that.

GrabCad doesn’t seem to have a model of it, but if you can take a pair of calipers to it, we can probably figure something out.

If you live where you can get to a Lowes and they have the Kobalt router on sale… That makes a pretty easy purchase.

the diameter of the router is 2.42" but it has a part that sticks out by 0.43" and 0.67"wide. but it looks like i can file that part off.

That’s around 61mm (61.47), which MIGHT fit snugly into the Makita mount. Not sure if it is better to butcher your router with a file, learn enough Fusion360 to design a custom mount, or spend a few bucks and get a cheap new router (Kobalt on clearout at Lowes, or a Makita clone from Vevor.com)

The Makita mount (as per my recent measure) has a printed opening (before any flexing to tighten or loosen) of right at 65 mm I think.

Remixing to make the opening smaller is not enormously difficult. If I can get time later one I will try to work one up.

Before you do that, Doug, recall that there is that protrusion on the side:

it has a part that sticks out by 0.43" and 0.67"wide.

He said he might be able to file that off, but I would advise against it. What worries me there in doing a remix is the angle that the protrusion is at relative to the router head, and whatever mechanism is present to be able to tighten the router collet. Also, measuring to 0.01" isn’t super accurate. Probably enough for 3D printing, but recall that the difference between V1 “J” parts and V1 “F” parts is 0.4mm or 0.015" so closest 0.01" might not be the accuracy that you want for a CNC mount.

So I’d want to know where that protrusion is relative to the collet lock, and also relative to the router head, so that I’m not trying to put the router in with the head pushing into the core, or making it impossible to change bits in the collet without removing the tool.

Ideally, I’d have the tool in front of me so that I could test fit, too, but I’m not about to buy one…

Before you do that, Doug, recall that there is that protrusion on the side:

He has drawn a plan that accommodates that protrusion

the diameter of the router is 2.42" but it has a part that sticks out by 0.43" and 0.67"wide.

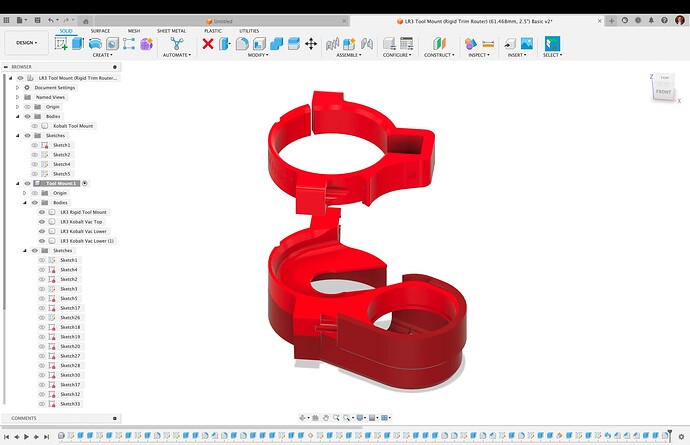

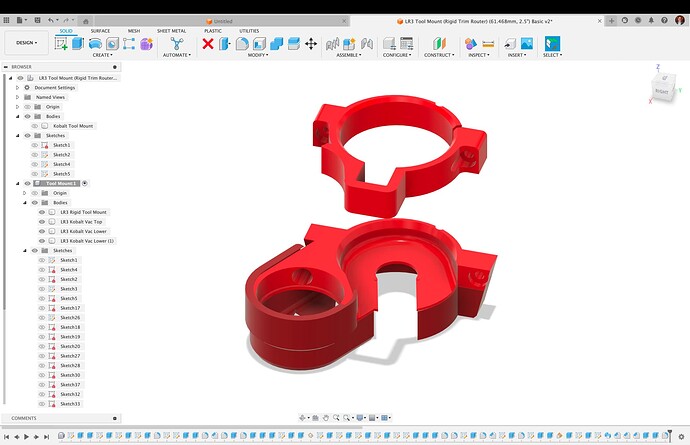

Dave, the attached is based on the drawing you sent me. Whether that design is useable, you can tell after you print and try it out.

As per the email I just sent you:

I worked this up using Ryan’s Fusion 360 file that he graciously shared, which was his work for a Kobalt Tool Mount, and I used it to create a Rigid Tool Mount, as per your drawing.

Let me know if this works!

LowRider Rigid Trim Router Mount for David Gethings halfdonedave54@gmail.com.stl.zip (121.4 KB)

PS: obviously you would need to print 2 of them. Also, for the dust shoe part at the bottom, you can get that from Ryan’s Kobalt dust shoe on Printables, or his Makita dust shoe on Printables.

Ridgid R24012 router

Dave, something to be aware of on your Ridgid R24012 router, is the speed range of the thing. I think the manufacturer’s page indicates the range for RPM is 20,000 – 30,000. By comparison, both the Makita 700 series and the new Kobalt trim router, that sadly did not get picked by Kobalt as permanent, have their lower end speeds down around 10,000 RPM.

Most of our use of CNC machines such as the LowRider and MPCNC, is with our router operating between about 10,000 to 25,000 RPM. It would seem that the lower end of that range (10K to 20K) is missing from the Ridgid R24012.

If you are careful about your feeds and speeds, you may well be OK.

Why this all matters: If a CNC machine had infinite rigidity and its stepper motors had infinite magnetic grip strength, and the teethed gear pulleys had infinite grip on the belts, and the bit was impervious to deflecting (bending) under heavy load, you could select high feed rates and speed rates with heavy chip load, and go to town.

But since bit deflection is a thing, and there are reasonable limits to the above mentioned machine capabilities, the chip load will usually need to be a bit more reasonable and the feeds and speeds, while they can be quite nice and fast with a LowRider, do have reasonable limits. The ways to accommodate a more reasonable feed rate… include a reduced speed rate on the RPM of the router.

If you keep the RPM rate up, while slowing down the feed rate (of motion through the material), then instead of the bit getting its needed chance to bite off mouthfuls of the material, it will just be rubbing and creating friction. The bit can get very hot very fast, and this causes the metal to become soft, and the bit can get dull very fast. We often refer to this as a burnt bit or a toasted bit.

There is a wide variety of options on usable combinations of feeds and speeds, because you can adjust both numbers (feed rate of motion and RPM speed rate on the router) in tandem. Raising both can be good, lowering both can be good. There is a relation between the two numbers, and for any range X of one there is a corresponding sweet spot range Y on the other.

One of the best ways to understand this is to think about changing only one number, the feed rate, while leaving the router speed unchanged. Imagine this (but don’t really do it): set your Rigid router on its slowest speed. Position the spinning bit against the material, with no additional motion. In short order, your material will be on fire. All friction, and no cutting.

Then, let’s go to the other extreme. Leave your Rigid on 20K, but go with a very high feed rate, pushing too hard and too fast into the material. The bit won’t get hot, but your steppers in your CNC machine are going to start skipping steps, and the bit is going to bog down in the material. The bit may break off, or your CNC machine may be dragged to a screeching halt.

The sweet spot is somewhere in the middle between those two extremes. The slower your router can spin (and still stay cool enough) the more options you have on feeds and speeds.

The bit, when taking bites out of the material, is able to transfer heat into the chips being cut out, and when those chips fly up out of the flutes of the bit, they are carrying that heat away from the bit. Hope this explanation helps.

PS: the Kobalt I mentioned, that was not picked up, is now being “blown out” at clearance prices. Several of us have gotten them for $89 or $69 or $49, and one recent listing showed the $100 router being sold for only $24.92. Kobalt router - #606 by nate

Usually the online Lowes.com listings say “in store only” — and the store inventory is not properly reported online, and the stock in the store is often not located with the other routers, being either in a seasonal Kobalt display, or on top of the shelves, or in back. Sometimes you can find them by persistently getting help from kind employees.

My Lowes.com, when set to my current store, just recently lowered the price from $89 something to $54.97. ![]()

The Makita mount… 65 mm

Yes, my mistake. I was going off memory, which is declining more rapidly than I would hope…

close older topics to help with spambots, and faster new user questions.