I was hoping to keep everything socket head cap, but my Ace Hardware options were limited. Either way, this looks solid.

Wow! DJ’s setup is nice, but at this point, I only have enough 4040 for the outer frame. I’ll stick with EMT legs since it’s cheap and easily extendable. I’ll likely just slide in a length of MDF to use as spoil board as needed.

Thanks for the pointer.

You are welcome. It also gave me a chance to ping him for his yearly reminder to come visit me. ![]()

Are you also building a LowRider next to it? Tag team? Both MPCNCs at once? ![]()

Yes. This is what happens when your desire for a full-sheet CNC outpaces your ability to build a table or room in the garage to put it. The Primo seems like a portable footprint to tide me over until I can get my stuff straight.

I’ve done similar with my vorons. I built my 2.4 first and then my 0.1 for small quick prints. I envision the same with the Lowrider and Primo.

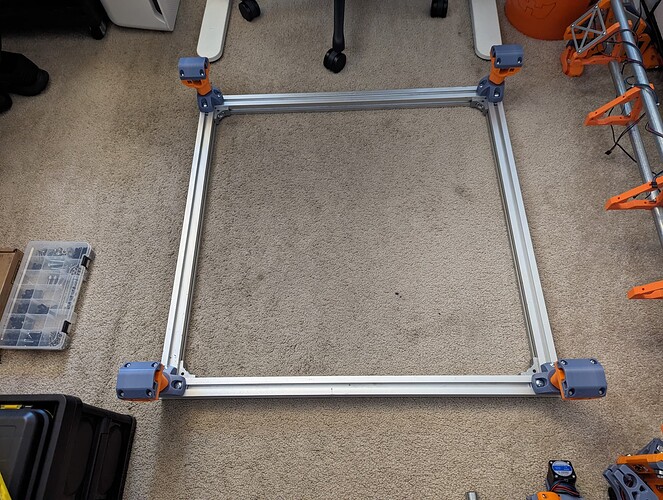

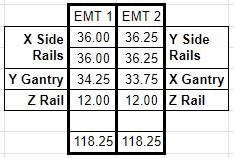

I love it when the math just works out. I had already cut the feet rails from a leftover length from my side project. The remaining parts fit cleanly in 2 x 10-ft lengths.

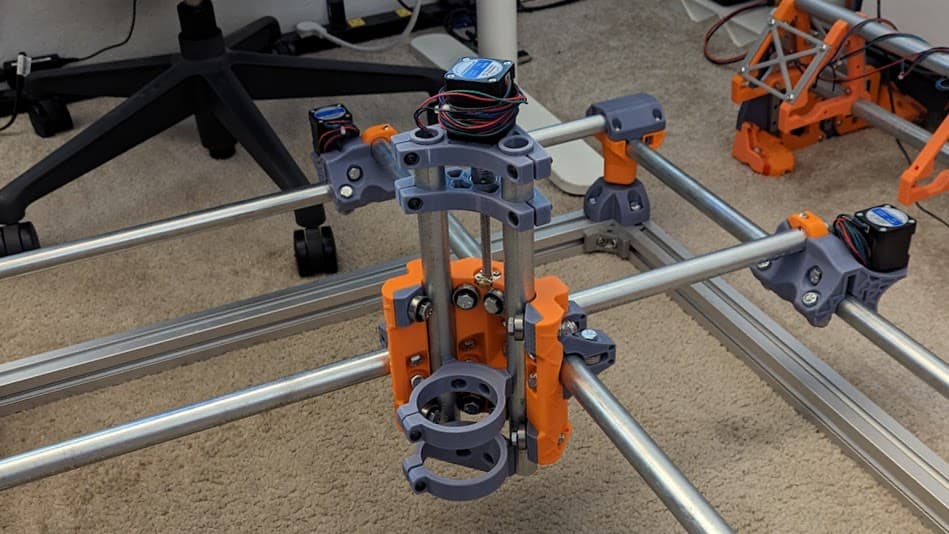

Well, that was a bit of a pain. My holes are not centered because I’m bad at these things so I opted for enlarged holes to compensate. I learned 2 things. 1, I need a drill press. 2, I need a small warehouse for my new drill press, Primo, and Lowrider.

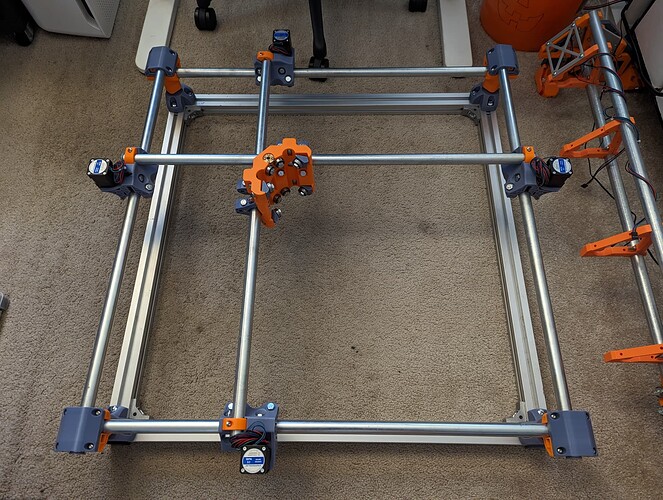

It’s all worth it, look at how good those look, sharp colors.

Do this one first. It’s easier.

I installed the belts this morning before work. It’s feeling much more solid now. Next up, wiring. I like the portability of the 4040 base. I think I’ll build a control box that is easily removable or maybe install it in the back corner where the tool head can not reach.

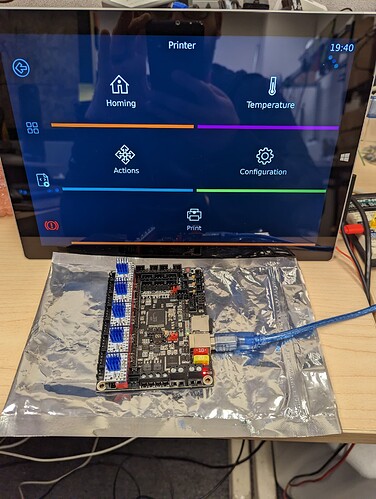

This may be overkill, but I just found an old Microsoft Surface 3 Pro in my “junk” pile (slight hoarder tendencies). Instead of running the BTT Manta M5P, I was thinking of running Linux/Klipper on the Surface and using an old SKR 1.4 I have in the parts bin. I could run all kinds of control interfaces and still have more than enough horsepower to run klipper. Either way, it’s good to have options. ![]()

Also in my searches, I came across an interesting dust shoe design from @ESmith that is currently on the printer. We’ll see how it all turns out.

Ahhhh, dare to dream. Unfortunately, a warehouse is not in the budget for this project at this time. ![]()

I printed that shoe for Schneewittchen, it is pretty good. There have been a few more people printing it here, you lose ~5mm, but that’s okay. Now that I have the LowRider the difference in airflow gets really, really obvious, the small channels really hold a lot of air back. Works completely fine anyway (if you don’t mill 6mm MDF with a 6mm endmill at 2000mm/min. :P).

Thanks for the experiential feedback! Since this is still technically my first CNC (Lowrider never saw action), I still have much to learn. If eventually, I need more suction, there may be a way to slightly modify this concept to fill all open voids in the farthest corner of the MPCNC by using a more asymmetrical shape to maximize airflow. Once I get it mounted this evening, I’ll see what there is to work with.

It is a great design and works well, don’t worry. ![]()

Well, now the obvious thing would be to run it while driving…

There is not a ton of room for the shop vac and the kids. ![]()