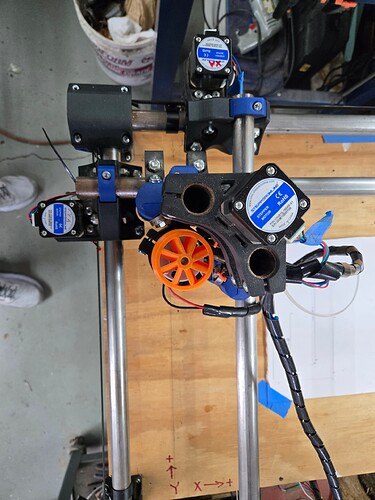

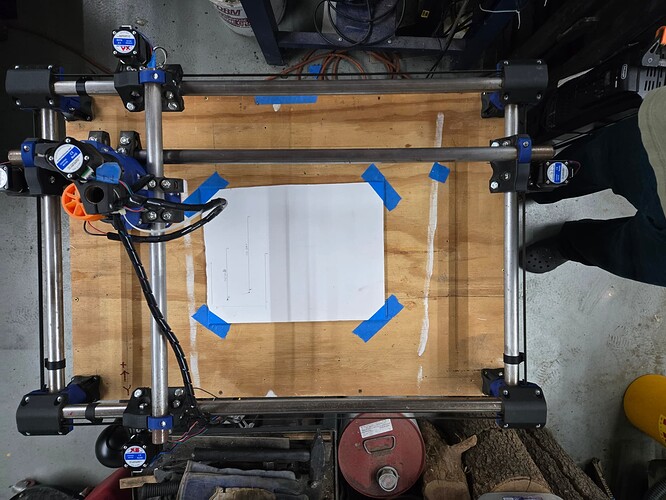

So I was measuring my usable work (cutting) area today, and discovered that I only have 12” in the Y-axis dimension, but about 26” in the X-axis.

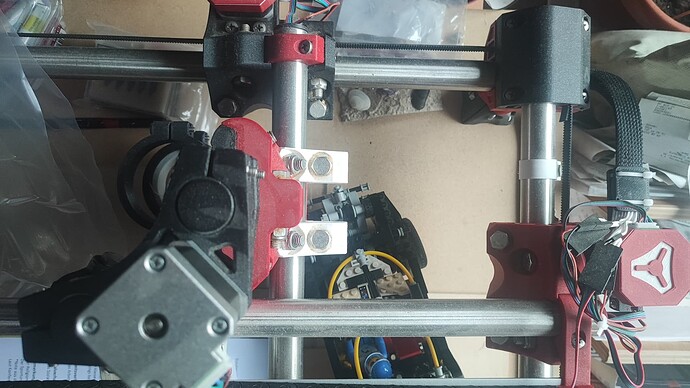

I looked closer, and see that it appears to be because the core mounts (sorry for incorrect terms) are contacting the truck. Is this just the design, or is this machine incorrectly built? It doesn’t seem right, but I didn’t assemble this machine, so I can’t say if it was done per the instructions.

As configured, I’m losing a bit over 6” in the Y-direction due to the arrangement of the mounts and motor offset.

I’m just curious, really. It doesn’t look like there’s much I can do about it. But maybe there is? ![]()

Swap the X trucks right for left. The core mounts are supposed to go to the other side, like they do for the other axis.

I think I understand…maybe. That’s gonna suck. I’ll gave to disassemble about half the machine to flip them around. ![]()

I looked through the assembly instructions, but just couldn’t follow very clearly. The docs seem to assume that you kinda already know what the machine is supposed to look like, I think.

I’ll give it a shot when I get some time, but it may not be right away.

In any case, thanks for solving the mystery of the missing cutting area! ![]()

EDIT: I spoke too soon. The more I look at it, the less I understand the issue….

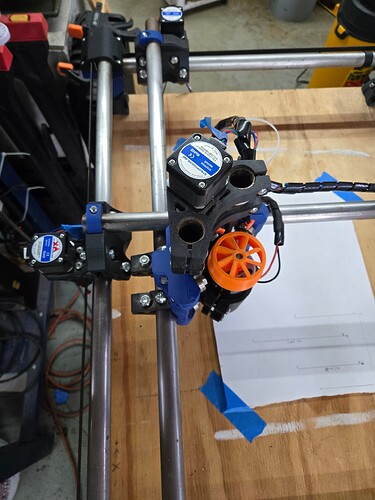

@SupraGuy , when you say ‘swap the X trucks’, do you mean like this?

Aren’t they two of the same design? I can’t visualize how swapping them would change the geometry. I think you must be describing something else, right?

Okay, so I went back out and took another photo.

Comparing it side-by-side with this shot from the assembly docs, I swear I don’t see a difference….

What am I missing?

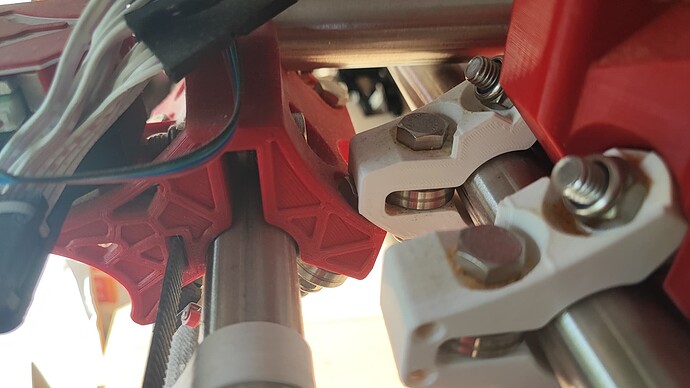

Hmm…

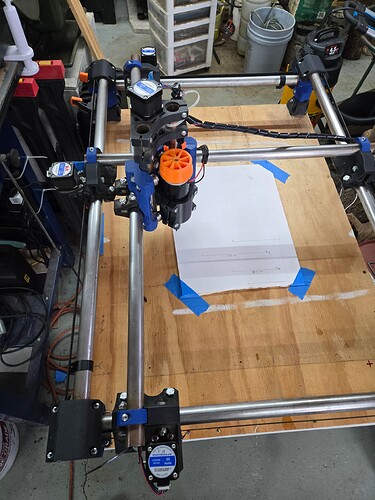

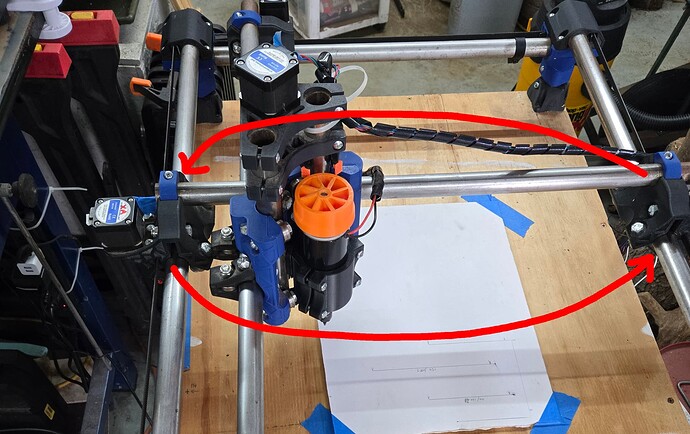

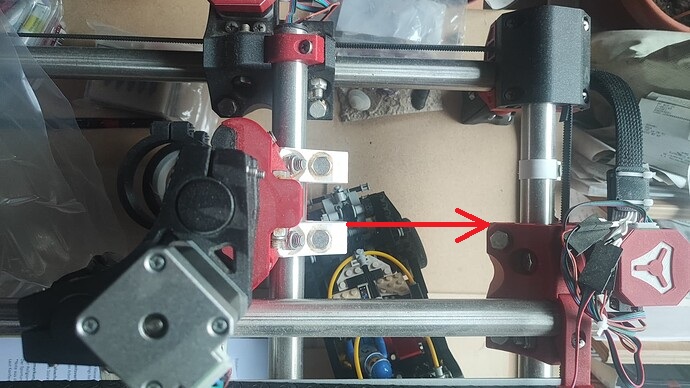

So if you were to jog the machine in the direction indicated by the red arrow below, would the white bracket contact the red truck, or would the white bracket pass over the bolt head on the read truck, allowing more travel in that direction?

Ah. I don’t think mine is like that. I need to look closer, but my core brace runs right into the face of the truck. I wonder if the original builder printed the wrong part?

Even if I made that change, it would only gain me about another 1/2” or so of travel. It seems odd that it’s designed to lose so much in the Y-axis. Ryan designed everything else about this machine so well, I feel like I’m still missing something here.

How much X and Y cutting area do you have, if you don’t mind sharing? I’m trying to get a feel for how these machines typical go.

Right now, I have only 12” of Y travel, but about 26” of X. The frame ratio looks reasonably balanced, so those numbers seem…off.

There are 3 braces that are the same, only one differs. Maybe he didn‘t catch that. You are not missing anything, the rail is on the back and there is no way to make it magically disappear. ![]()

I used to have 750x550mm, but that was a bit too much, there was chatter in the middle of the workspace. I know reduced it to 400x400 workspace, but it‘s only a plotter now.

You can find more information here: MPCNC Primo Schneewittchen Reanimated - Oldenburg, Germany, there‘s everything to know. ![]()