Me too, but I finally went and bought some extrusion because I don’t trust myself to get everything right on the first try. The first redo would make the milled panels cost about the same, so, extrusion it is.

What filament would you use to print parts for a Repeat V2 that you want to use for printing ABS/ASA? Can you get away with PLA/PETG even if side panels are enclosed?

My Repeat V2 will probably be dimensioned to fit inside an IKEA Lack table.

For the record, I’m using the milled panels in conjunction with the extrusion similar to how the Railcore design uses milled panels with the 1515 extrusion. I have an extrusion frame with 5.5mm plywood skins, which makes the whole thing super solid. Still wiring, so no idea what it does for noise.

Unless you are planning to heat the chamber to more than 50°C PLA should do the job. I printed my parts with PETg and I want to have the option of printing ASA so that I can use 3D printed parts in the car and not have them hopelessly deform in the summer. I had a tachometer housing done in ABS that looked pretty funky after a warm sunny week…

Same plan over here, but I’m more concerned about dust than noise, since mine will be in the shop.

Prolly the same it does for the railcore, RESONANCE CHAMBERRRRRRRRRRR! ![]() I’m still experimenting with trying to cut that down, but haven’t found anything that really works well yet.

I’m still experimenting with trying to cut that down, but haven’t found anything that really works well yet.

Yeah, I more or less expect the panels to act like the sound boards in a stringed instrument. Noise isn’t really a big deal for stuff in my basement though, and the rigidity is ridiculous.

So far I’ve tried sound deadening mats for cars, didn’t help. Took that all off, which was a pain in the ass, and bolted C channel in an X across the panels, also didn’t help that much. I keep looking into masking off the extrusions and casting epoxy granite onto the panels, but haven’t decided if my printer is heavy enough already. ![]()

How loud is your repeat?

Do you run Marlin FW?

I wonder if resonance tuning would help (Klipper Firmware)…

Resonance tuning will help the print, but not the sound of the machine. That’s coming from the steppers.

Marlin has resonance tuning as well.

What holds the z Belts in the end holders?

Folding the belt over on itself, or adding a piece of filament in the fold, or a second small piece of belt on top of the other. Depends on how good your prints are.

Thanks, Any chance you could post a picture? Sounds dumb but I have at least three scenarios in my head from that ![]() Does the slot have room to tuck it back in?

Does the slot have room to tuck it back in?

It is the same as the LR3 Belts, there are a few pictures in those instructions.

Got it!

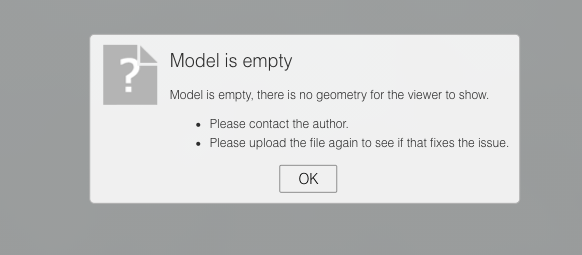

Anyone else getting this on the fusion link?

Nevermind, works fine if you open in fusion 360.

Maybe because I was having issues this morning and most features are currently hidden.

Ryan,

Can you point me at the sketches for the Z Belt holders. I cant seem to find them in the Fusion files. I want to make a slight mod to them to open them up a little on the bottom/top side.

If you click on the feature it will highlight the extrude or cut, from there it is typically the sketch before that.

Just make sure it is not a printer calibration or tuning issue before you start editing the files. If you have a printer thing going on, all the parts will need edits. The Z belt parts can be fed through by cutting your belt to a taper, if you loosen it up by more than 0.1-0.2mm it will not work and the belt will pull through.