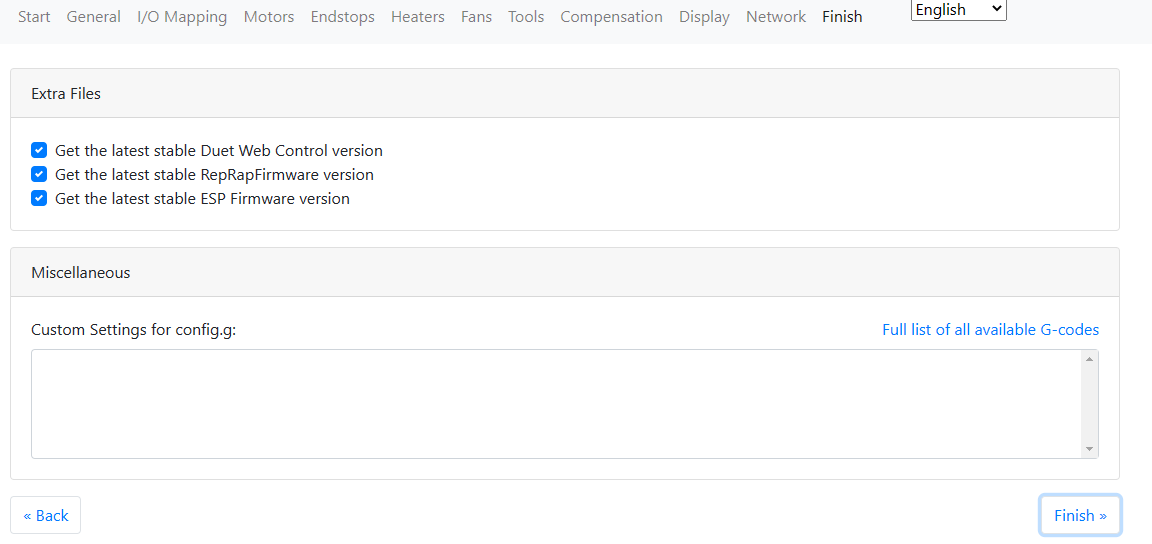

ok, had some other things to do… but somehow I felt I had to try this stuff first

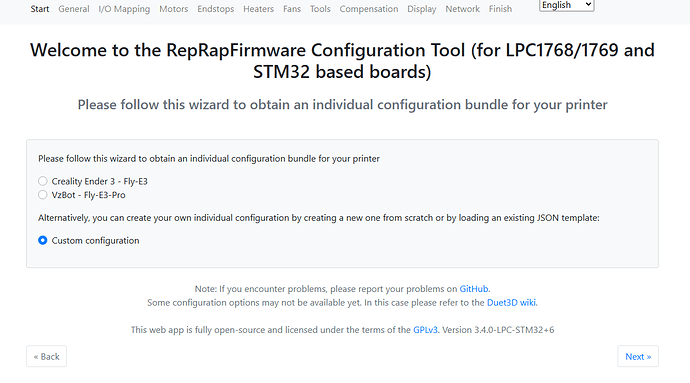

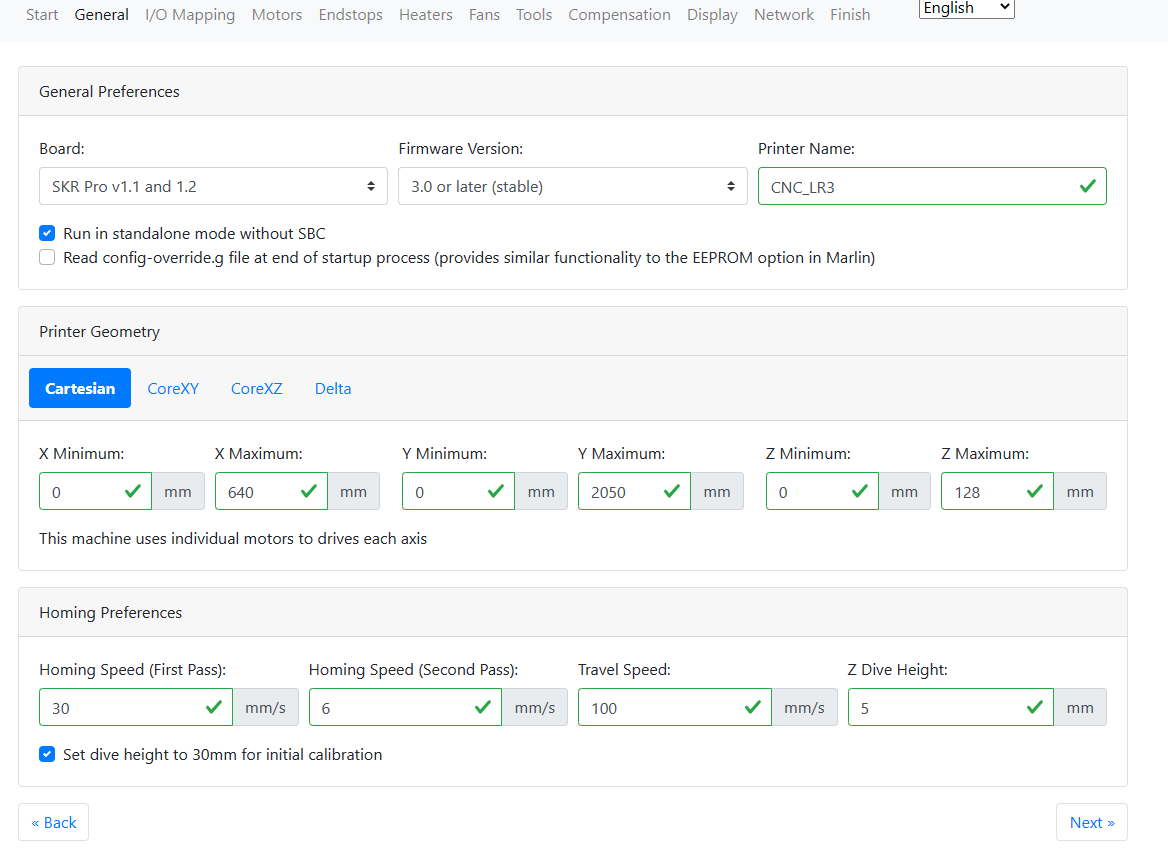

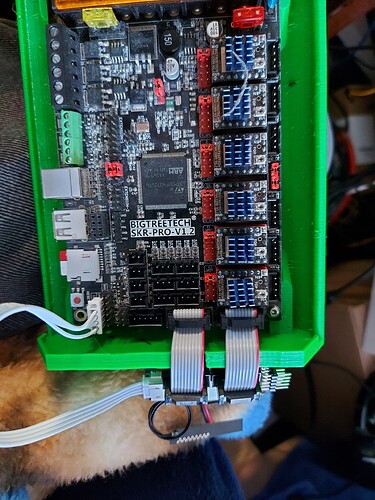

I got RepRap running on my SKR Pro 1.2 although I had to experiment quite some time.

Must confess I will probably stick with RRF if I can get it all running. There seems to be some very nice features I didn´t have on Marlin (like not being able to move outside my bed area, needing to home first before I can move, auto increase Z height on moves… some basic stuff that I had some issues with in the past that will make life easier).

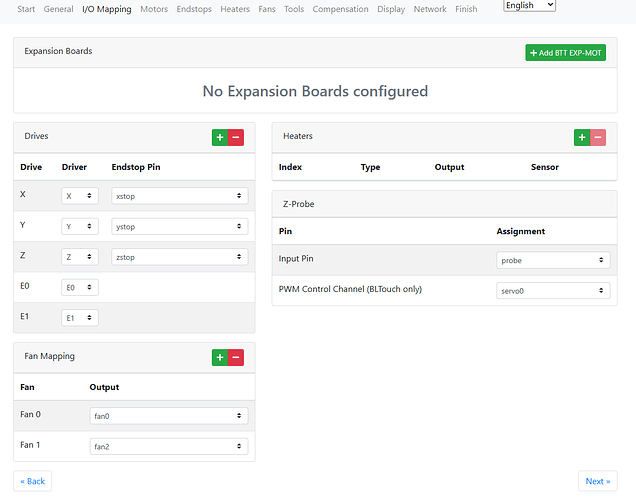

I didn´t manage to get the display working using EXP1 & 2. But that wont be a big deal as in the end those will be used for the wifi adapter. So I updated “board.txt” to the following config, to remove those settings:

// Board Hardware configuration file for SKR Pro

// generated by RepRapFirmware Configuration Tool (LPC Version) v3.4.0-LPC-STM32+6

// on Fri Apr 07 2023 12:00:45 GMT+0200 (Midden-Europese zomertijd)

//Note: Each line should be less than 120 characters.

// : Unwanted options can be commented out or set to NoPin. Lines commented out will get default values

// : for pins the default is NoPin.

// : Values for Arrays need to be contained within { and }

// : Comments can be defined with // or # (comments are not supported inside arrays)

// : Each config entry must be all on a single line.

board = biquskrpro_1.1;

//LED blinks to indicate Platform is spinning or other diagnostic

//Comment out or set to NoPin if not wanted.

leds.diagnostic = A.7;

heat.tempSensePins = {}; //Max of 3 entries

//heat.spiTempSensorCSPins = { }; //Max of 2 entries

//TMC Smart Drivers

stepper.numSmartDrivers = 5;

//Connecting a screen to a SKR Pro v1.1 and v1.2

//https://teamgloomy.github.io/skr_pro_screen.html

serial.aux.rxTxPins = { PA_10, PA_9 }

Next, it took me some trails before I got the display running. I know it was working since my fans ran so figured it would be some issue with baudrate. As I am using the latest V1 TFT firmware I had to grab those settings (250K)

M575 P1 S2 B250000

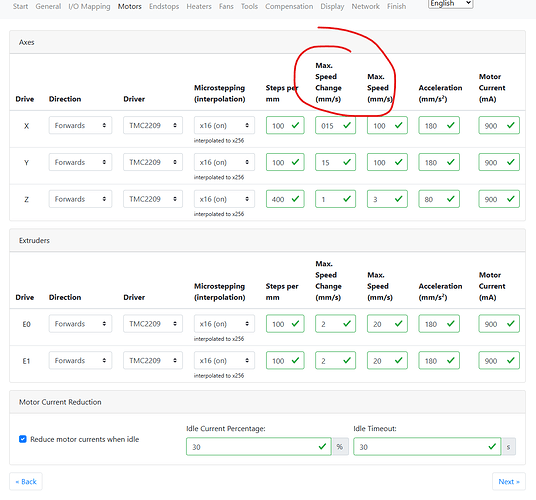

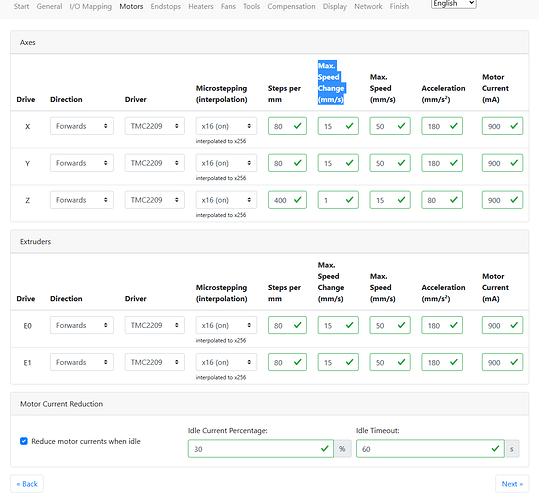

I previously used the steppers on my LR2. During some firmware upgrade 2 of the steppers had been reverted in coding. Obviously that came in to play as they now wanted to go each into another direction

So I had to modify the running direction and that seemed quite easy in RRF! Love it

; Drives

M569 P0 S1 ; physical drive 0 goes forwards using default driver timings

M569 P1 S0 ; physical drive 1 goes backwards using TMC2209 driver timings

M569 P2 S1 ; physical drive 2 goes forwards using default driver timings

M569 P3 S1 ; physical drive 3 goes forwards using default driver timings

M569 P4 S0 ; physical drive 4 goes backwards using TMC2209 driver timings

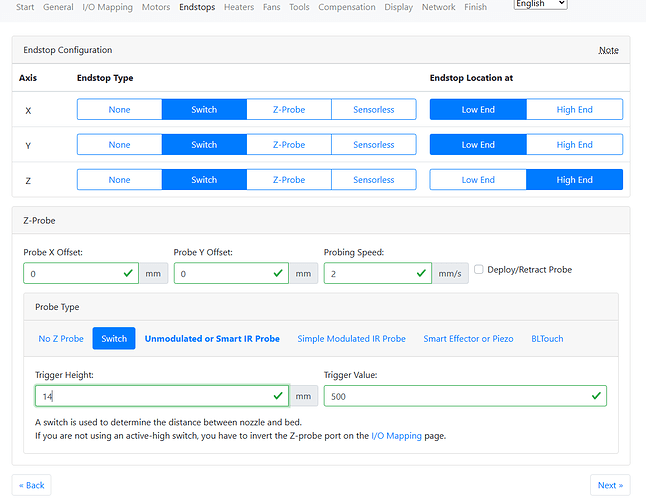

This did the trick for me, to activate the X endstop.

However for the Y´s I had to change your settings as the combination did not work. (still have to check that each endstop correspondents to the correct motor)

; Endstops

M574 Y1 S1 P"^ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

M574 E0 S1 P"^e0stop"

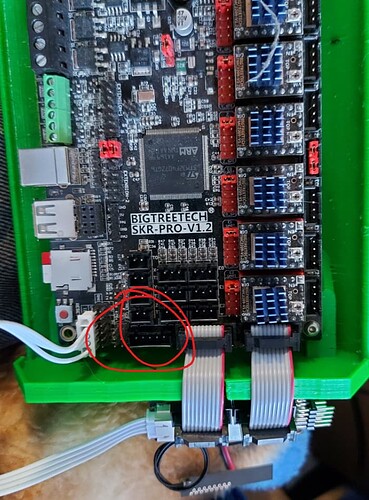

Unfortunately I seem unable to figure out the settings for the Z endstops.

I now have the below code. Re-reading your previous comment I consider adding an exclamation to see if that helps.

M574 Z1 S1 P"^zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z1 via pin zstop

M574 E1 S1 P"^e1stop"

A short homing session (without Z) worked fine on X & Y. So I am confident to get all things working just fine.

Important to note is that the SD card needs to be insert all the time to work. I hope I will manage to get USB stick to work too as I am not a fan of using the SD card (during my quick tests I already corrupted one :s ).

I will also need to reconfigure the TFT. The error “no printer connected” remains on the screen although it all works. In the BTT github I´ve seen a separate config file for RRF so that will likely have some fixes for it.

![]()