Hi All and thanks for anyone’s help on this ![]()

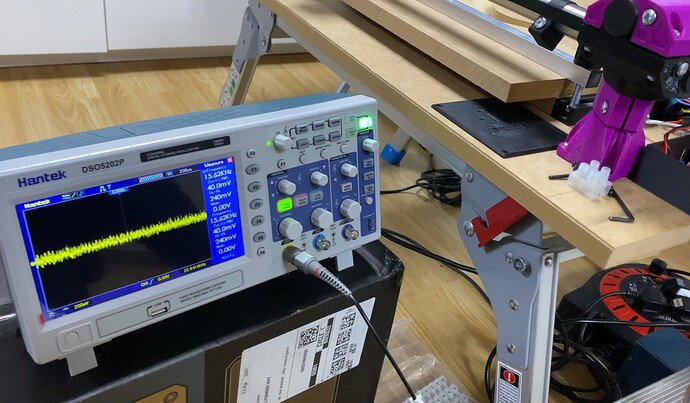

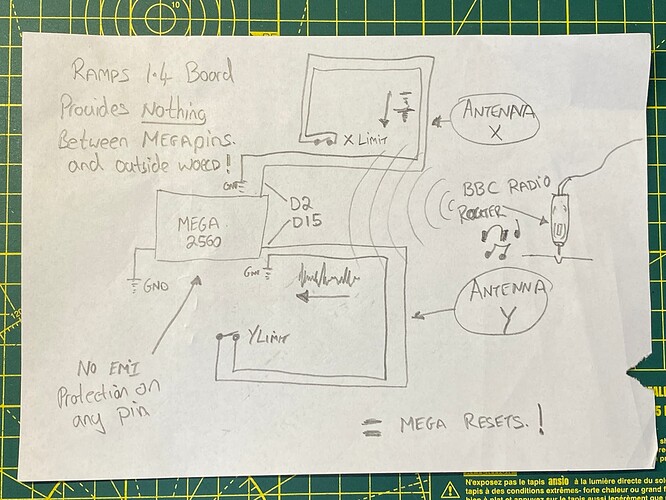

I have been chasing a (semi) Random “Freeze” and also a Random Reboot issue on my MPCNC.

Mega Freezes or …in it did earlier in this escapade Reboot on its own.

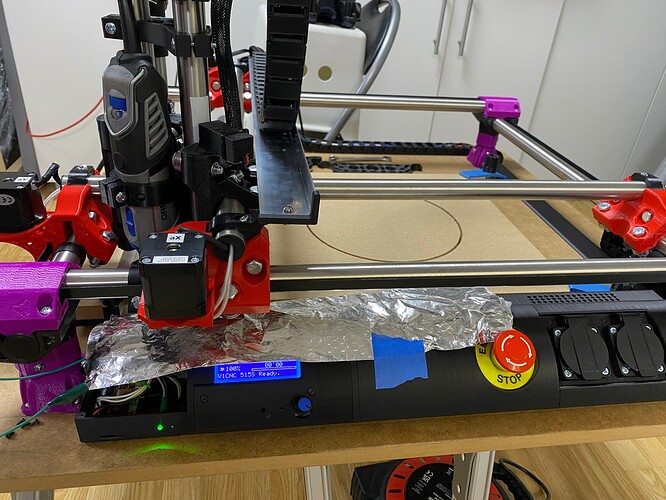

We seem to have tracked it down to occurring during a loading up of the tool. During cutting free air (repeating the failed areas of cuts prior to tool engaging)it seems to be just fine.

With or without octoprint connected (so from SD) the error still occurs. Our max feed is 2500 and depth is no more than 0.5mm 30k, and step over 0.25-0.4mm. So low loading and many passes. Dremel is lightly changing its tone with a very slight drop in RPM.

Tried:

Replacing the Mega

Swapping out to a completely separate PSU

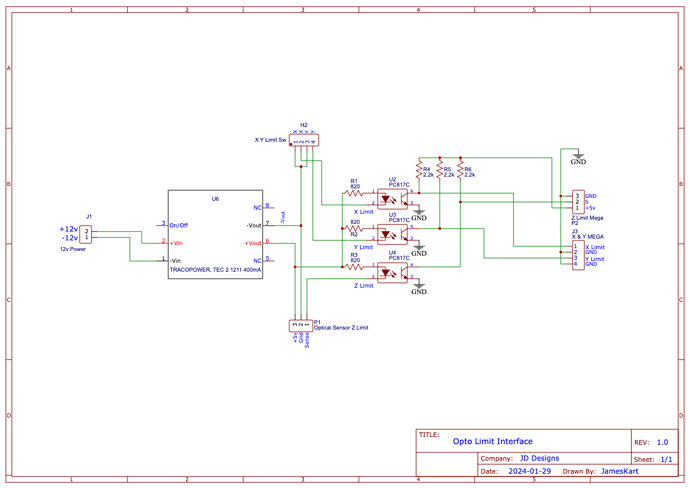

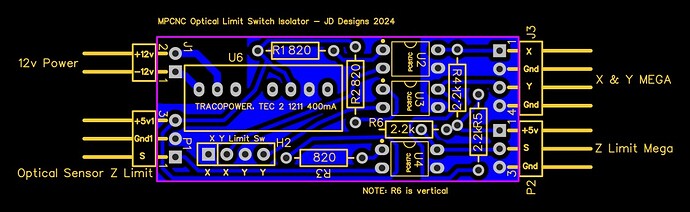

Disconnected my optical Z limit to see if its a noise related feedback to the Mega (thought id got it Doh nope!)

Checked Driver temps after several hours 54.5C max on the driver boards.

Wiring and connects are new and tight

Adjusted the Speed of the Dremel to see if its a random noise freq issue.

Adding more bypass Caps to the incoming 12v supply to the Ramps 1000uF 100nF etc.

Add more capacitance to the Mega 12v rail (vIN ) and also doubled the 5v from 47uF to 100uF 100nF.

Unplugged Pi and ran from SD

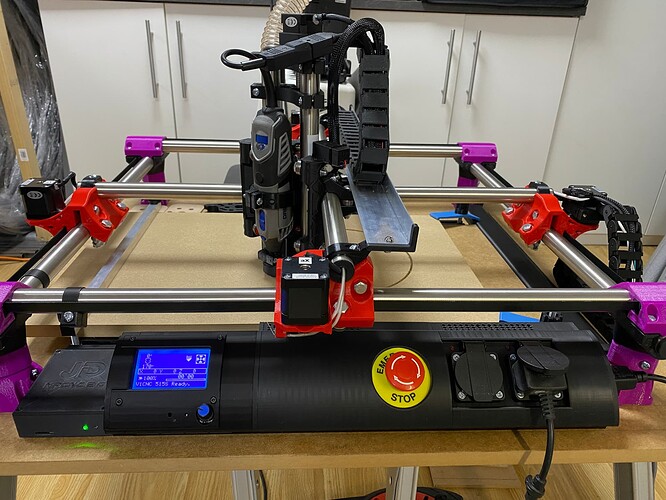

Equipment Summary:-

Ramps 1.4 , 3x DRV8825 (set to 1.2-1.4A peak per phase )

Arduino Mega (Original and have also sapped out for a clone to test)

Marlin 2.0 V1 Ryans Firmware 515s 2.1.1

Dremmel 4000 and Vac controlled by 2xZero Crossing 25A SSR opto isolation

Meanwell 8.5A Chassis Power supply

2 x Standard micro Limit switches

5 x 17HS19 steppers

Cables are 18awg silicone, loomed, with drag chains.

All power electronics are contained within right side of console.

Left to right are : - Octopi running on Pi2W, Ramps and Mega, SSR block, EM stop, PSU and sockets.

Im literally at loss as to what this could be - does anyone see what i’m missing ? I must have missed something. Myself and my son are just lost what to do next, we really tried but …hope maybe some one can help. Thanks so much.