Im kind of scratching my head here. I think Im trying too much at once.

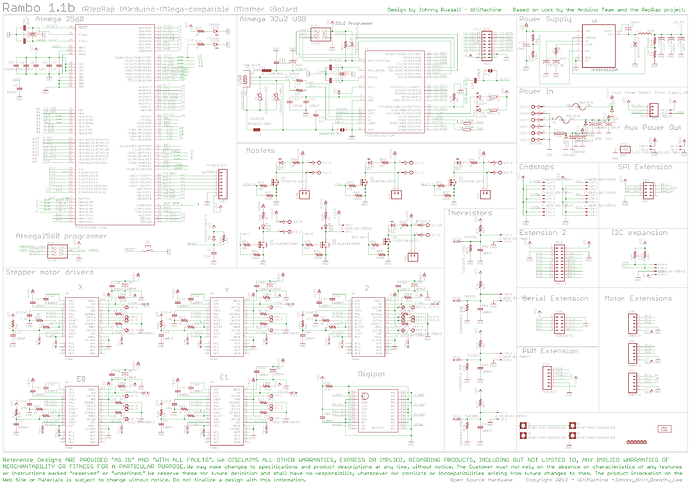

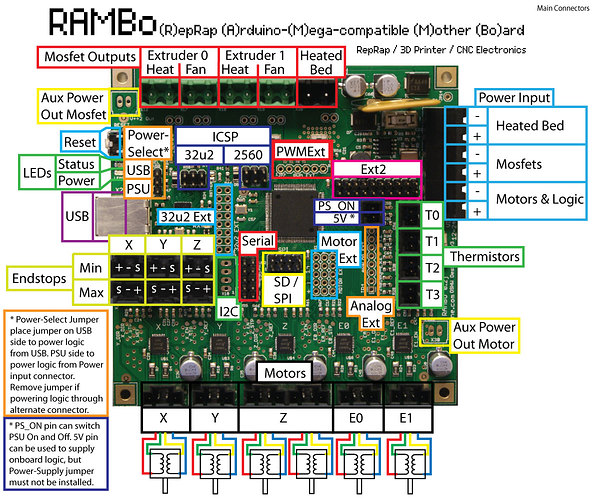

I have an endurance 10w laser with their laser control module that should respond to TTL. I have hooked up the TTL wires to my Rambo 1.3 running Marlin 2.0, I got it from Ryan. I got version number from the read out :

""echo:Marlin bugfix-2.0.xecho: Last Updated: 2018-01-20 | Author: (none, default config)echo:Compiled: Mar 7 2018echo: Free Memory: 3785 PlannerBufferBytes: 1296echo:Hardcoded Default Settings Loadedecho: G21 ; Units in mmecho: M149 C ; Units in Celsiusecho:Filament settings: Disabledecho: M200 D3.00echo: M200 D0echo:Steps per unit:echo: M92 X100.00 Y100.00 Z400.00 E100.00echo:Maximum feedrates (units/s):echo: M203 X120.00 Y120.00 Z30.00 E25.00echo:Maximum Acceleration (units/s2):echo: M201 X400 Y400 Z400 E8000echo:Acceleration (units/s2): P<print_accel> R<retract_accel> T<travel_accel>echo: M204 P400.00 R3000.00 T400.00echo:Advanced: S<min_feedrate> T<min_travel_feedrate> B<min_segment_time_us> X<max_xy_jerk> Z<max_z_jerk> E<max_e_jerk>echo: M205 S0.00 T0.00 B20000 X3.00 Y3.00 Z0.20 E5.00echo:Home offset:echo: M206 X0.00 Y0.00 Z0.00echo:Material heatup parameters:echo: M145 S0 H196 B92 F0echo: M145 S1 H240 B110 F0echo:PID settings:echo: M301 P17.98 I0.98 D83.62echo:SD init fail""