Love it! While you are at it. You may consider a V1 version of this…

Shoot, as long as a good test exists I don’t want to replicate it. I can link one of those, going to need to make a docs page out of all these tests soon.

There are good torture tests and print calibration tests out there, I need to get some good machine calibrations tests out so these giant Core’s come out perfect instead of leaning or skewed.

I’m seeing ZX and ZY, and I assume XY is covered by the other test?

Maybe also horizontal holes 8mm, 5mm and 3mm since the holes mostly print with the axis horizontal.

Yup XY is the first test. I can add it to this one with a diagonal measurement, but it is just better to compare.

The horizontal holes is the only reason I have not released it yet. and an M5 nut spot.

Printing it now to see where I stand, on a printer I have already tested.

Maybe also 23.5, 25, and 25.4 mm holes (maybe go / no go) that people can take to the store so they don’t buy the wrong tubes.

Although that’s probably overloaded for something that’s primarily a printer test and deserves its own separate part.

interesting idea

I added an ABL to my ender 3 along with a PEI bed surface. I went a tiny bit overboard and got a fancy motherboard as well. I powered it on and got zero smoke, so I like to think I’ll be printing tonight.

I’ll start printing calibration pieces. I have calipers, but I can’t say how accurate they are aside from testing against a metal ruler. I feel like +/- 0.25mm on 150mm could be measurement error as easily as it could be a print property. What options are there for verifying calipers? I’m pretty sure only expensive calipers have provisions for calibration.

Calipers are plenty fine, rulers will work if that is all you have.

Does it make sense for the diagonals to have flat spots for measuring? Or is it easier with them round?

Flat spots mean corners, corners can bulge, round gives a nice accurate place to measure.

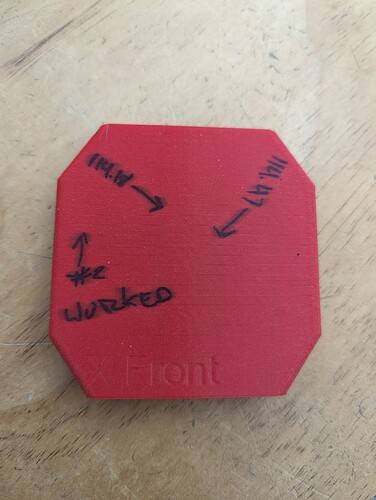

Thanks for this! I ran the test below to check the z-axis after running three iterations of the x-y test. It’s certainly not comprehensive, but it seems good enough for checking the squareness of results along with x-y-z lengths. All axis are reasonably square, aside from warping on the test below and each axis measures +/- 0.15mm at 100mm. I did adjust the steps/mm for the y-axis by a fraction of a percent. I believe this is largely due to the y-axis not being square with the z-axis. Fortunately, both that and the slight x-axis sag seem to be within the margins of compensation or at least acceptable error.

I forgot to link it, I published this test. If any of you are brave and want to see how your printers really are…

https://www.prusaprinters.org/prints/38846-zx-and-zy-printer-frame-test

I’ll try it when my new hot end parts arrive. Rounded the end trying to unjam some petg. Also killed my thermistor.

Thanks for this topic and the posts.

For initial calibration, have been happily using https://teachingtechyt.github.io/calibration.html#xyzsteps. Great for tuning esteps/temp/extrusion/retraction and other printer settings.

To check/tune XY dimensions/diagonals, I’ll try…

https://www.printables.com/model/36412-xy-size-and-square-calibration-print

Thanks to @Jonathjon’s MP3DP Build topic today, I stumbled across Printables > V1E > zx-and-zy-printer-frame-test and this topic.

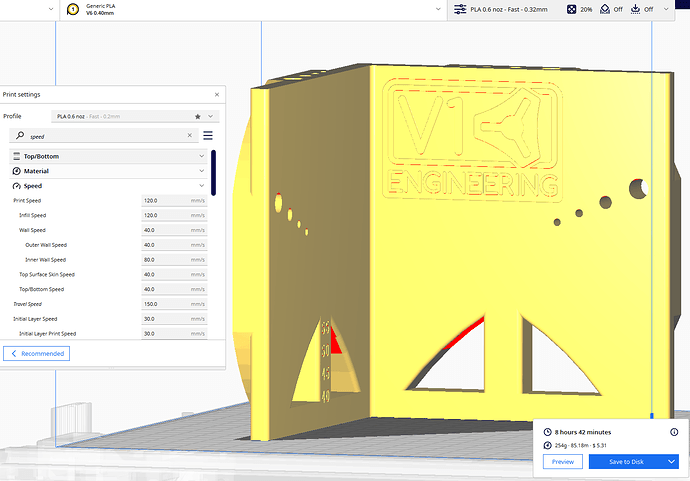

The model checks for lot of things, but also take lots of time and filament… Maybe my config’s wrong (0.6noz, 0.32 layer height, 2 walls 20% infill) ?

Curious if there’s a more lightweight faster model people like to use for dimension/diagonal/skew/frame checks?

Was expecting to see something like…

Lots of Printables > Test models out there, but figured on checking if people here have something they like for quickly checking print dimensional accuracy?

I think its because this one model checks a LOT of different things at one time. And ones that are V1 important as well. It does take a while to print but I do think its a real good test

I print a tall rectangle 150x150x10. I print it xy, then at 90 degrees. I only use that for checking diagonals.

My big one does them both at the same time. I usually just adjust one at a time so I use a generic rectangle brick