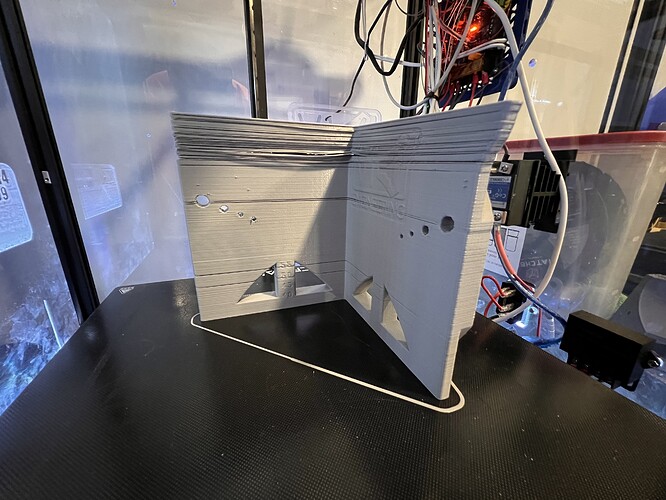

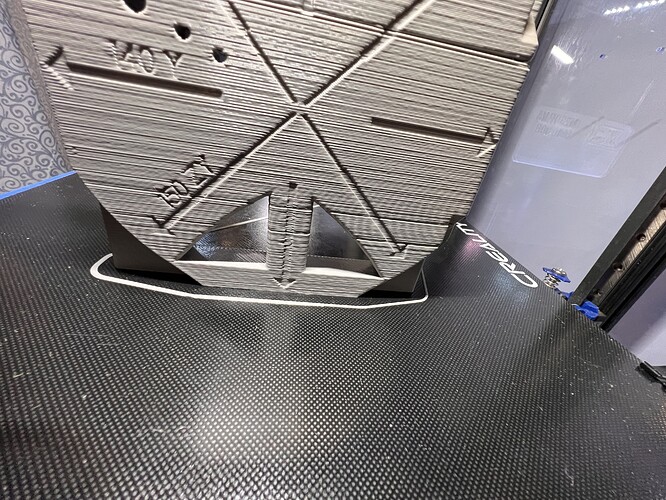

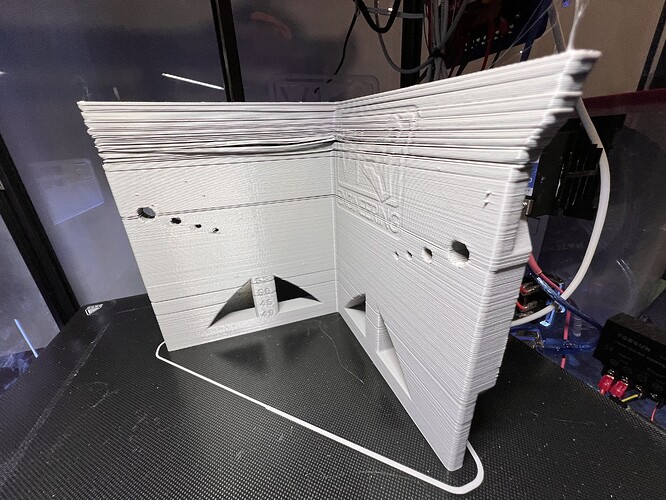

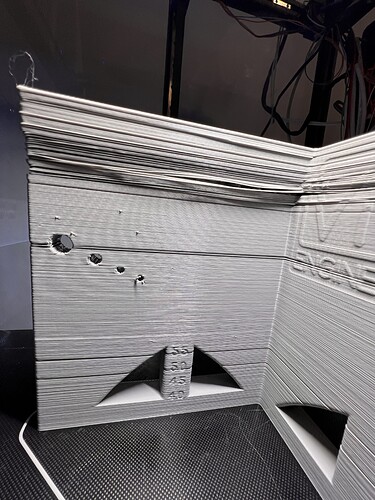

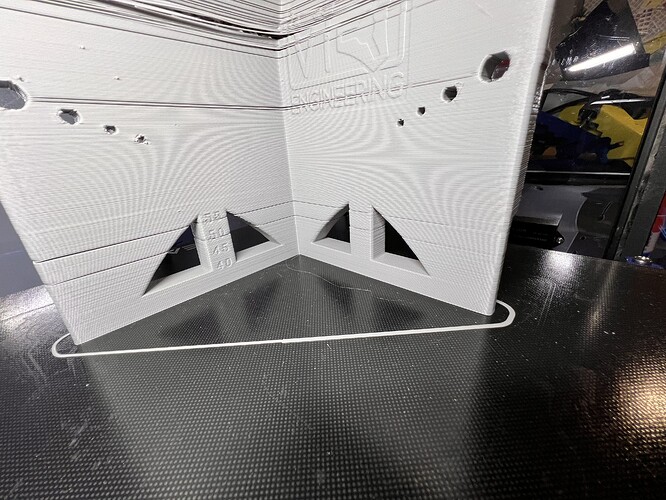

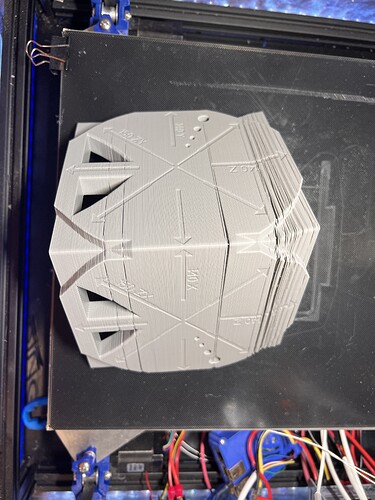

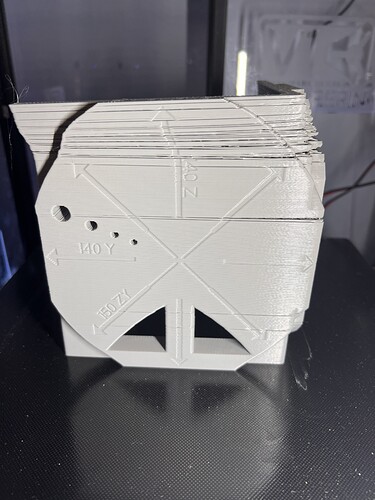

Ok I’m at a loss for what’s going on here. It started off beautiful. When I went to bed last night it was around the 45 and I remember telling my wife I think I’ve finally got it. This look like the best print to ever come off this printer. Then I wake up to this. It looks like it started losing steps on the back z motor you can see the line is straight across the back but angles towards the front making it look like it was level where it should be in the front. Then it lost steps in y only. Not angled across. Print didn’t mo e on the bed. Does anyone have any thoughts on what I need to check. Pulling my hair out with this thing