Is it just me or could one just watch that go back and forth for hours???

The sound of the acceleration…gets me every time.

Yes. I want to build one of these just because it has some cool motion and sounds!

That’s pretty slick!

An update…

Brain fully-engaged with the r&p project and with a nicely dialed-in printer at hand… just couldn’t get on with the MK3S build that still languishes.

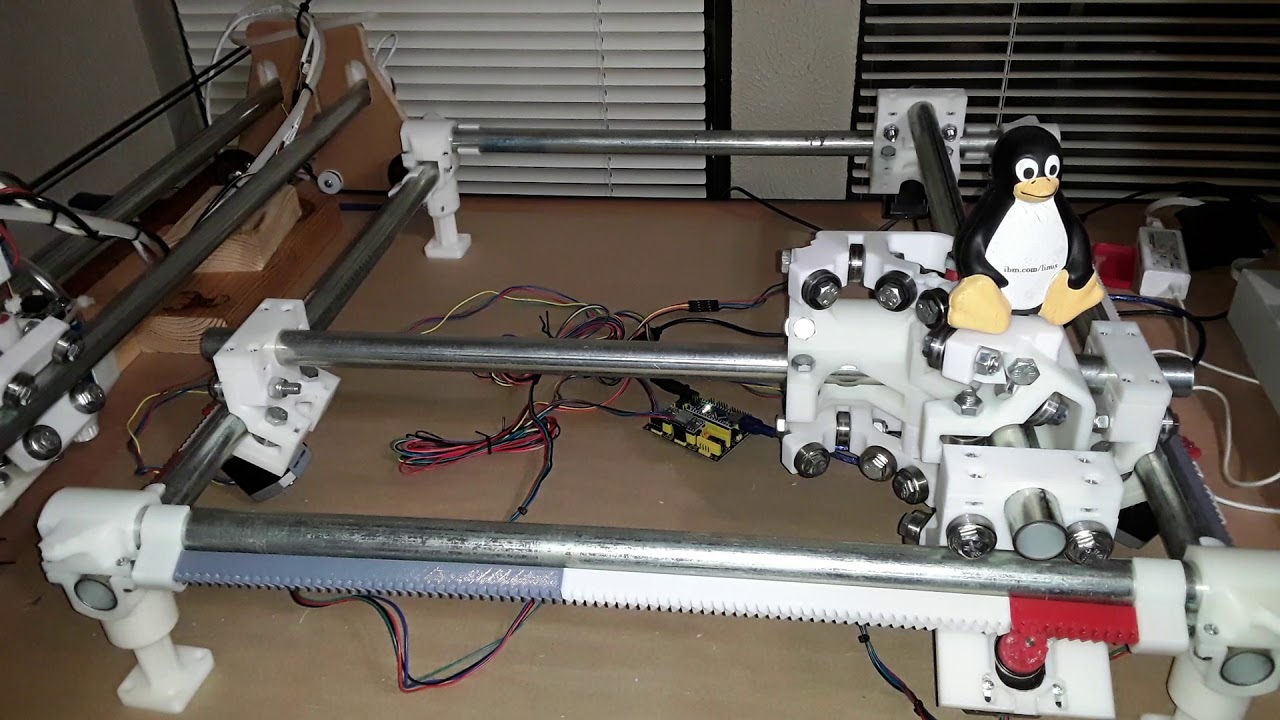

So I have been madly printing and adjusting to the point I now have a somewhat loud, but functional, MPCNC X and Y axis.

The machine is currently being driven by an inexpensive Nano-based CNC board, with DRV8825 stepper drivers, and running Grbl 1.1. A Pi ZeroW, with Jeff’s V1Pi image onboard, is running CNC.js and seems adequate to the task so far…

Each tractor (roller assembly) consists of three printed parts… body, motor mount, and gantry clamp.

The racks are made up of multiple sections and strung up on a 1/4" threaded rod, cut to the desired length for each axis…

and capped on each end with a printed part, which snaps onto the EMT rail, and a nut…

Aside from a quickly printed, custom, foot (can’t find my tubing cutter after the move), the corners are standard MPCNC. The plan is to keep the MPCNC stock, with the exception of the rollers for X and Y.

Later. – David

Interestingly, during testing with only one tractor/roller assembly, the weight of the motor always rotated the whole assembly by 120 degrees… which was fine because it also allowed me to see better the r&p engagement. It may have been a figment of my imagination, but there were times when it almost seemed to run a bit smoother and quieter in that underslung condition as well. So, I fired up Onshape once again and fashioned another bolt-on piece to support the gantry tube while in that orientation. This is what I came up with…

The red piece is sized to fit between the “outriggers”, shares the bolts with those bearings, and is identical in thickness and height to the standard/upright orientation so that the gantry tube spacing is retained and the yellow gantry clamp can be used in either position.

The “upright” orientation looks a little cleaner and more compact but enlarges the machine’s footprint slightly and hides the r&p works from sight…

and the alternative “underslung” orientation is taller but lowers the CG and allows the r&p works to be seen more clearly. The entire roller assembly must also be rotated to put the r&p works to the outside of the machine…

In it’s current condition, I have one axis “upright” and the other “underslung”… yet it retains the same gantry rail-to-rail spacing as before. Since this machine is still very rough and the operation is not as smooth as it will need to be, I’ll flip the other axis to “underslung” as well, giving me a better view of what’s going on as I continue to test it…

More to come. – David

In your first picture, with the rack under the conduit, you could spin the motor around 180 degrees, and the wires could go straight into the conduit.

Obviously this putting wiring neatness above being able to see the R&P in action. Maybe it only makes sense on the ‘back’ rack?

Yeah, right now I’m still testing/retesting and building/rebuilding too much to worry about the wiring… just trying to get reliable, smooth operation from the r&p setup. But I’ve always been a “function” over “form” kinda guy anyway… and rarely truly “finish” anything. So, wire management isn’t generally first priority with me… though I do normally use the conduit to get the wiring for a motor pair all coming to the same side to go to the controller. I’ve built enough of these machines I know it all works out fine for my purposes… so, right now, it’s “first things first”.

I do like Onshape for designing 3D printed objects. The user interface is less complicated than Fusion. I get so lost in all the options with Fusion.

I just love seeing this creative process unfold! Thanks for sharing.

Finished up a middle assembly (using bolts and nuts I had on hand) and installed on the R&P machine…

A few photos of the middle assembly and machine. These are the first Burly parts I’ve ever printed and assembled… nice!

I guess now that I’ve taken it this far I ought to go ahead and build the Z-axis as well. I feel compelled to plot the obligatory crown… and a few of Jamie’s rulers. After that, I’ll just let the spirit lead… ![]()

Later. – David

Does the R&P induce any vibrations into the assembly?

I really don’t know yet. I just got the machine to this point late last evening and haven’t had a chance to do any testing yet. I know it sounds pretty rough – and probably always will – but AFAICT the motion of the axes seems reasonably smooth, just eye-balling it. I think plotting the crown and a bunch of Jamie’s rulers will tell us a lot more about it.

So, my plan now is to complete the Z-axis so I can do those plots and try to calibrate it. All is not lost, of course, if it doesn’t really pan out. I’ll just be four stock MPCNC roller assemblies away from having a new Burly MPCNC, in any case.

Personally, this is the kind of stuff I love to do – always have! – and I’ve had a blast doing this project. In truth, I get a bigger kick out of messing with the tools… than actually using the tools to produce something useful.

– David

Understood. I was just having a hard time trying to tell from the video if the penguin was bouncing around much.

Tux was one of the things I was watching… he didn’t seem to be bouncing around at all. AFAICT he was impressed and seemed to be enjoying the ride…

He is so sharp looking, it felt like he was photoshopped in.

It is a super cool project, and you are an example that I would like to follow when I retire.

My biggest worry with the R&P is just backlash. The Herringbones I’ve printed needed to be a bit loose to work smoothly, and then they had some backlash. I’m trying not to mud sling, it is an awesome project (have I said that already?).

Wash your mouth out… ![]()

Thanks for the kind words. But please realize that my time is my own only because I am “single”/alone… and mostly deemed “unreliable” because I’m old/forgetful. If I didn’t have this stuff to occupy my brain and time… I’d be bored to tears and probably institutionalized. ![]()

I’m hoping that Jamie’s test pattern generator will help here. When you create a ruler for an axis, it actual generates TWO rulers, side-by-side… going first in one direction and then coming back in the other. The tick marks on the opposing rulers should line up nicely with little/no backlash. If there is appreciable backlash, I’m hoping it should be pretty easy to see…

You prefer GIMP?

Don’t really have need of either very often but, yes… I’d prefer Gimp. When I “stage a scene”, it’s REAL, man… it’s real. ![]()

Ok, here it is…

After getting the Z-axis printed and installed (too tall and I still can’t find my tubing cutter…), I did a rough calibration and air-milled the crown. Stole the pen and holder from MPCNC “Henry” and did a first shot at actual plotting. The finished plot…

A prime example of my wire management strategy… actually, shows the little Nano-based KeyesStudio CNC board running GRBL 1.1h and the PiZeroW running CNC.js.

I’m pretty stoked and encouraged with the result so far.

Later. – David