For any Inkscape users out there…

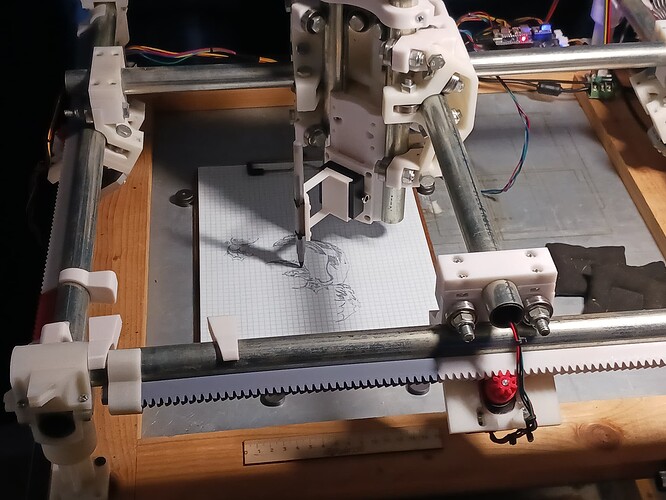

I’m not entirely sure why, but after mentioning using Inkscape and the JTech laser plugin for pen plotting in my post above, my curiosity got the better of me. So I’ve spent the past couple of days playing with different versions of both Inkscape and the JTech laser plugin on my Chromebook. Things have changed over the past couple of years… Inkscape is now up to version 1.2 (vs 0.92 from before) and a newer 2.5.1 “community version” of the Jtech laser plugin is alive and well out on Github. I was able to get both installed and running… pretty simple thanks to “appimage” technology.

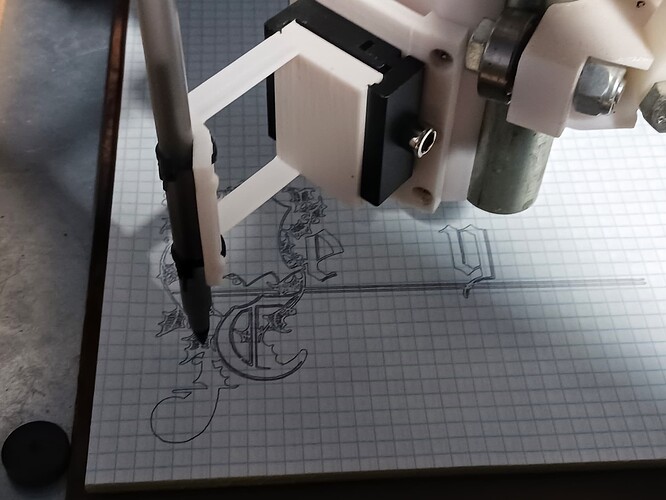

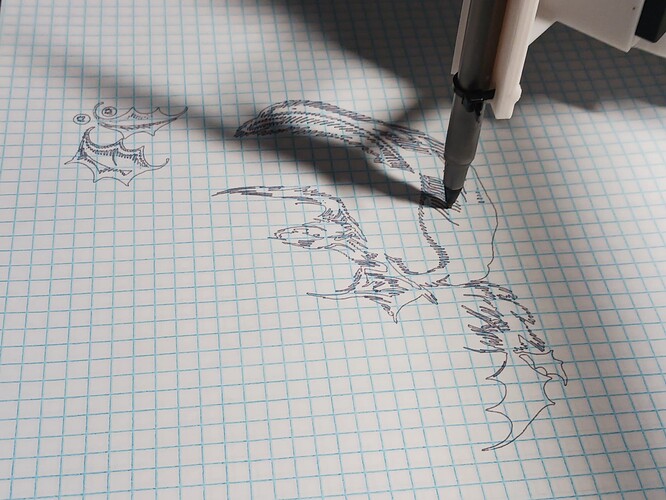

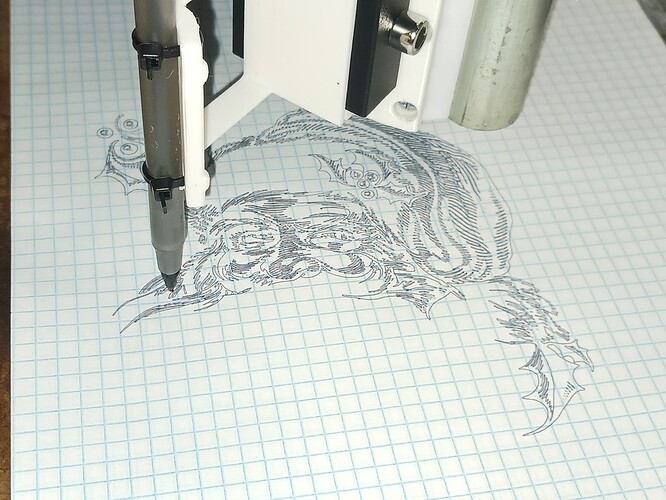

As mentioned above, I used Inkscape and the laser plugin when I was still running Marlin-based machines… for both laser and pen. Back then most of us were using the RAMPS fan pins and M106/M107 for laser control IIRC… and the plugin allows for specifying the laser ON and OFF commands you needed. But I also “discovered” (from somewhere I don’t remember…) that the ON/OFF commands could also take the form “G0 Z-0.5” or “G0 Z2.0” to lift a pen up and down. It does work though the gcode isn’t the most elegant and requires a tiny bit of editing… note the pen wasn’t lifted before returning to the start, leaving and unsightly line that doesn’t belong. But Grbl has no trouble with the pretty generic gcode… and I suspect Marlin won’t either.

Oh BTW… stay warm and Merry Christmas, y’all!

– David