Haven’t seen snow since I made a snowplow for the ride on mower ![]()

Haha - the worst years the snow can come in October and remain until may/june! ![]()

I am yet to see snow fall, and I am starting to wonder if it’s not just some sort of conspiracy at play.

It always seems to happen the day before or the day after we are somewhere.

It’s not as though we haven’t gone looking, even in Siberia a few years ago, we experienced a week of 20 degree days (C) and glorious sunshine. .

Oof, I believe you posted photos last time as well. ![]() Sorry about the bad luck! I guess your area doesn’t have anyone from the city that can come out and mark underground utilities? In the States you can call and have someone come out before you start digging.

Sorry about the bad luck! I guess your area doesn’t have anyone from the city that can come out and mark underground utilities? In the States you can call and have someone come out before you start digging.

Yes, there’s a service for that here as well. But we’re just assuming that the municipality don’t have it, because this place is old and quite out of the ordinary.

There’s a funny insight to be learned from this incident: when we were digging two years ago I made sure to write down very thorough coordinates for the pipe connections. When we digging this time, I couldn’t find it, I was looking for it, over and over again. In the end, we decided “what the heck”, let’s just give it a try. The “what the heck”-method didn’t work out well…

After we finished digging I looked through my notes - and the coordinates were there - right in my face!

So - the lesson is: documentation is essential, but if your head doesn’t work well, things can go awful wrong.

Current status:

We had a digger bloke who we’d call in if we had a site with no documentation on services. No matter how unlikely the location, he could hit everything on the first bucket full. Saved us weeks of careful planning!

He was so bad at hitting underground services he couldn’t get insurance.

Trying to figure out how to make ridge lines!! This has been high on the list for years! Woho! Can’t wait to try it out on the plotter.

QGIS in action. Not sure how to rotate this thing though…

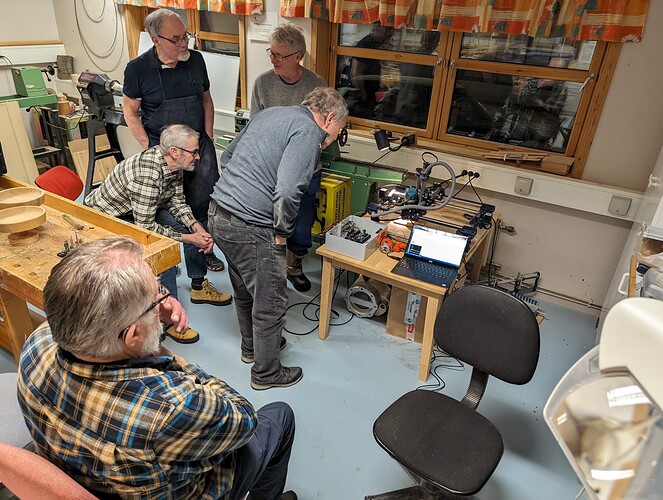

Club night at a local woodworking club. Showcasing the Primo. They all were mighty impressed, but many complained that the threshold for mastering all the necessary technical tools was too high…

I’m going to hell for asking this, but being I’m on the fringe of the democratic….

Is it a factor of old dogs and new tricks?

Or is the group the type that likes hand tools over automation?

I’m happy they were impressed, but curious if you had a feeling for the statement.

I bet there could be a carefully scripted workflow to impress them.

I am on their side, it could be easier. I would have loved to have been a fly on that wall. Wood workers that have used handsaws for more than clout must have had interesting comments.

Thank you so much for sharing with them and the picture with us!!

It’s funny, this club is a part of a association that is quite traditionalistic in terms of tool usage and aesthetics. (www.husflid.no)

But all the guys were very positive to the tool itself. They had a bunch of ideas on what to use it for. (Mostly sign making and carving, go figure)

When it comes to the tall threshold, I think we often forget how difficult computers are for many people. I was at a computer course last week at work for a specific program, and my mind was blown over how difficult it was for people to understand! The instructor was sweating and seemed almost desperate, people didn’t even figure out logging into their user on the laptops…

One of the guys tonight asked if it was possible to use the MPCNX as a physical Xerox. Can I use one object to duplicate it? Great question, but no simple answers!

They told me to get back to them when they could just tell it to do “what they wanted”. ![]() A great example of possible context specific AI. (OLLAMA anyone??)

A great example of possible context specific AI. (OLLAMA anyone??)

I’m pretty sure a lot of people can’t describe what they want well enough to be happy with that. Communication has two sides of responsibility.

Letting an unpredictable AI control super fast spinning steel is surely nothing to worry about!

Joking aside, I think many hobbyists and craftsmen can easily understand workspace and material matters. The biggest mental obstacle seems learning drawing/CAD/CAM and understanding the difference between a pixel and a vector.

This is actually the funny part, at least for me, since I have at least one friend and several visitors having made comments along the line of “the machine does all the work, what do you do?”

Glad to see someone noticing the difficulties of it and that the work does not lie only in the cutting. And even that’s not too easy. ![]()

That’s called a pantograph. I’m surprised they didn’t bring that up because that is old school tech. ![]()

Prepping for the local maker faire! (@vicious1 I didn’t ask for permission to print and use a big banner for v1e, but earlier interactions made me think that you’d be happy for the exposure…)

![]()

![]()

![]()

Love it!

Have CNC - Will Travel