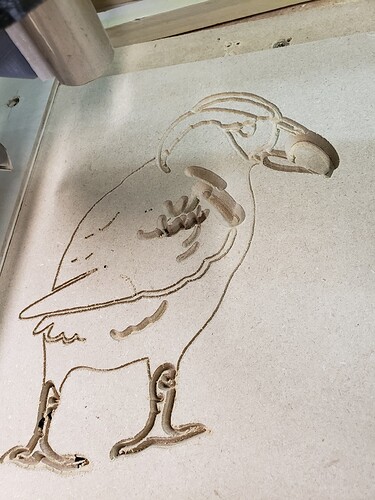

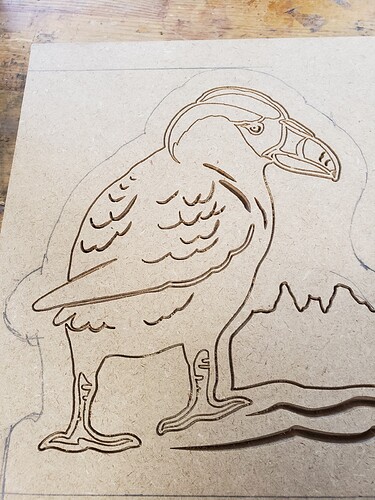

I felt i was doing fine, as i am very new, but then out of nowhere Z started plunging in at random times during the cut. I am reloading the same files and have tried changing max cut depths and widths but nothing is working. My problem seemed to be isolated to the carve function in EstleCam V11. I downloaded EstleCam V12, tried it, same outcome. I then noticed a somewhat similar issue with the engrave function as well. The difference with Engrave and carve is Engrave starts deeper than defined and stays at a consistent depth. Carve starts the same as engrave and then randomly digs in further. Any advise on how to resolve this issue would be greatly appreciated.

-Chris

Z started plunging in at random times during the cut

Does the machine recover, or, once it starts to plunge, does it remains too low? If it remains too low, then you are losing steps. There are many possible causes for lost steps including mechanical issues, electrical issues, and g-code issues.

The most common reason I see on the forum is driving the federate of the Z axis too fast. The Z-axis lead screw cannot be driven as fast as the belt-driven X and Y axes. The fix can sometimes be done in the CAM and/or the postprocessor, and sometimes it can be fixed by setting a max feedrate for Z in the control board firmware.

Beyond feedrate, check to make sure you do not have any binding on the Z lead screw and that the lead screw is well lubed. If you are using stepper drivers like the A4988 or the DRV8825, check you have the VRef set correctly. Check to make sure your bit and your router are secure.

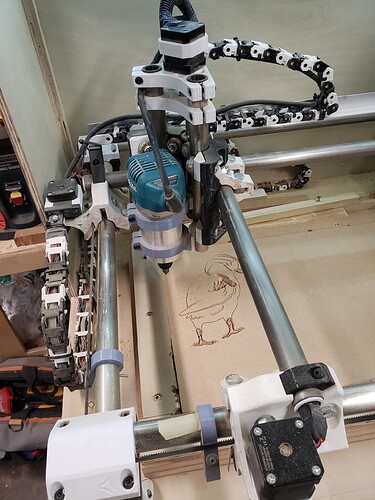

The picture of your cnc shows that the power cord to the router is hung up on the Z axis. I suspect that it hangs up for a bit then come loose and drops .

The other issue I see that you bundle the power cord with your low voltage stepper wire and possibly you limit switches. It is good practice to never run power cables parallel with Dc wires. Cross them is ok.

The router never moves relative the the stepper, the whole assembly moves up and down as one - that cable never slackens so it’s not hung up.

Lol,my bad.

Sounds like the z is not lifting as much as it should then plunges deeper. The other possibility is the mill is being pulled out of the router collet… Upcut?

Mostly it is missed steps because of the weight of the gantry and not enough amps on the motors with travel that’s too fast.