Working on wiring up my new Jackpot board for existing Primo build. I’m pretty comfortable with where the steppers will plug in, and while I have a little learning curve left on the endstop wiring, I’m not too concerned about that.

Where I’d like opinions is on my plan for the mains voltage (120v US) and controlling router power.

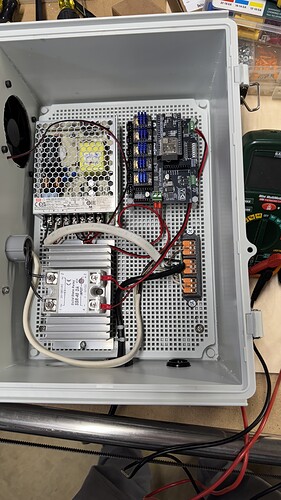

I’m housing everything in an outdoor box I bought for Christmas light projects that didn’t materialize this year, since the box has a nice grid for mounting, and plenty of room.

I’m powering the Jackpot and any other 24V stuff with a Meanwell 4.5A PSU (overkill, but I know it’ll be solid), and I have an SSR for allowing switching of the Makita router I’m using via a pin on the Jackpot.

I originally got an emergency stop button that would require wiring, but after reading some threads here, decided to order a Rockler router table switch with a paddle for the stop, and just plug the main power for the enclosure into that. Much simpler for wiring, and if I need to stop everything, it all goes, period.

My plan is to bring the AC cable (a cut-off PC power cable) into the enclosure, and terminate each wire with a WAGO 221 lever nut. One of the remaining 3 terminals on each WAGO would go to the Meanwell PSU, while the last terminal on each would be dedicated to a receptacle for the router, which would mount on the side of the box, allowing me to avoid butchering the router cord. The hot line of that would go through the high-voltage side of the SSR, with the LV side of the SSR wired up to a pin on the Jackpot, which I could then set up with either a macro, or control via gcode to turn the router on or off.

Also planning to have at least one 24v cooling fan in the enclosure, wired to the Meanwell PSU and drawing air from the bottom of the case (to minimize dust, though I might also add a filter) and exhausting it out the side .

If I wanted to be really safety conscious, I could put a kill switch on the door to the enclosure so that nothing inside can be energized with the door open, but I think I will likely be fine with the external paddle switch, or just unplugging it if I need to get inside. Might zip tie the door just as a reminder to cut power and zip tie at the same time. ![]()

Does all that seem like a fairly sensible plan?

I’ll post some pictures once I start getting things more fully wired up. I already have the PSU mounted and did a quick test wiring and boot of the Jackpot just to test it after it arrived in a rather beat-up box (thanks, USPS!), and all was well at that point.

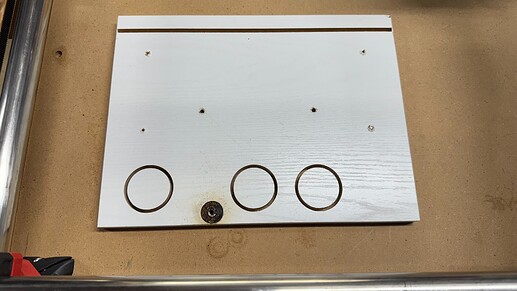

Adding an initial pic…this mounting plate screws to the back of the enclosure. Cooling fan will mount to the left of the PSU, and I’ll mount a receptacle to either the upper right, or lower left. More pics to come…