Today I picked up a mostly complete MPCNC from craigslist, and I’ll provide the description so folks can give me some pointers on what kind of work I’d need to do to get this up and running.

The Description

" This "Mostly Printed" CNC machine is currently configured as a "sharpie plotter," but has a functional 3d printer head and Dewalt DW660 router that are included. The MPCNC is a widely-used platform with a lot of community support and lots of adoption in the DIY community. Spare parts are printable with the machine itself, which is handy.

For more information, please visit https://www.v1e.com, the creators of the machine - this is a very flexible platform, and can be modified to have lots of other accessories (3d print heads, draw knives, laser cutters, plasma cutters, foam cutters...whatever you like!) However, as a diy-tier product, be prepared to sink some time into setup and calibration before you can use it. It's a great opportunity for someone looking to get their feet wet into CNC, but you'll need to know what you're doing if you want to get it running in a reasonable amount of time.

It's running off of a RAMPS 1.4 shield installed onto an Arduino Mega 2560 board. Control interface is a RepRap discount full-graphic smart controller, which allows you to insert an SD card with gcode and immediately start 3d printing or cutting without connecting a laptop. All power supplies needed are included.

Please note that this is NOT functional yet- it needs appropriate (free) Marlin firmware to be installed before it can be used. There are hundreds of dollars in parts here, and I have verified it works, but I am giving it away because I do not have the time to configure it, calibrate it, square it, etc."

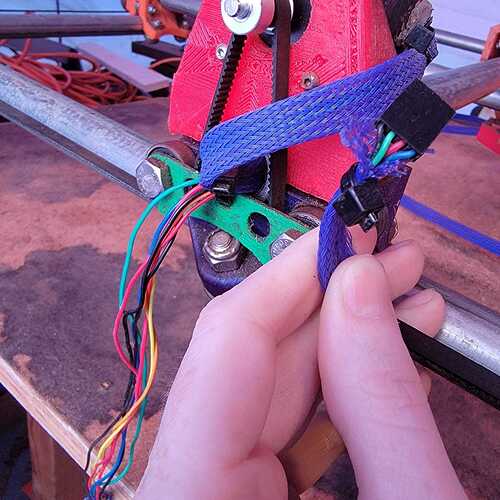

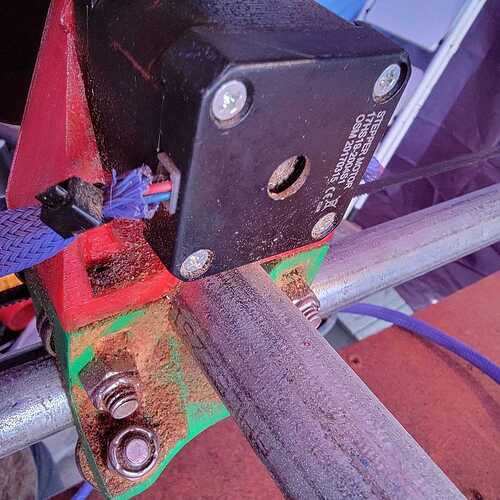

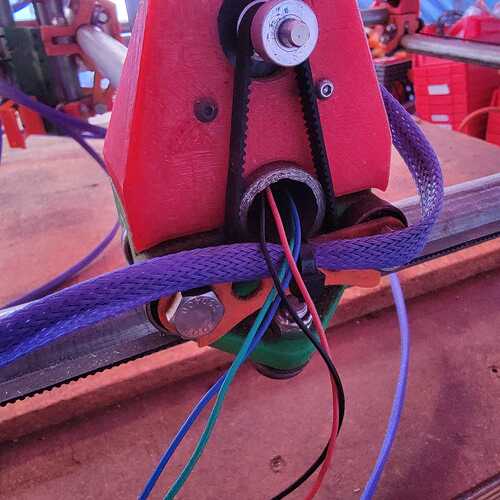

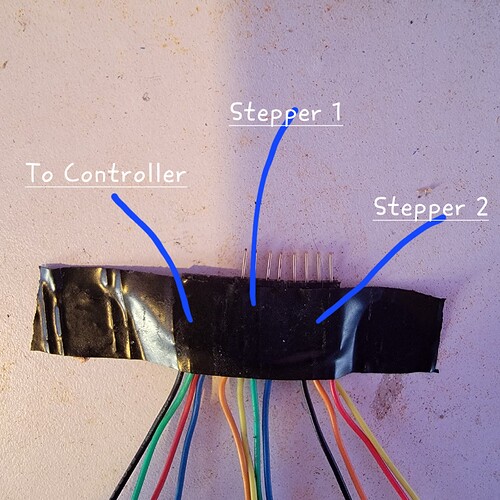

I haven’t put it back together again yet. I had to significantly dismantle it to get it into and onto my car. The electronics were kind of a mess and I plan on redoing all of this wiring and mounting anyway to protect them better.

I’m going to include pictures I took of the setup before taking all of the electronics off and removing the CNC assembly from the base. I kept all of the motors attached to everything because I wasn’t sure how to put it back together after taking it apart.

Some Questions

1 - Should I tear it down and rebuild from scratch (all the pieces) or should I just put the CNC assembly back into the base?

2 - Are there any pieces I’m missing to be able to actually mount the router to the core? I’m assuming it’s fairly easy to get these printed by someone I know that has a 3D printer.

3 - The 3D printer head the unit came with looks super jank, but it might also still work since I can see some evidence of printing taking place with the unit itself. Should I spin up a different thread for this so I can provide pictures of the 3D printer head?

4 - The person I got it from made mention of setting up Marlin firmware into the unit. This shouldn’t be too much of a problem for me since I know how to do this sort of thing, but I’ve never used an Arduino before.

5 - Is this going to cost me a bunch of money to get back up and running again, or is this mostly just around patience of making sure I do the setup and calibration correctly?

Pictures