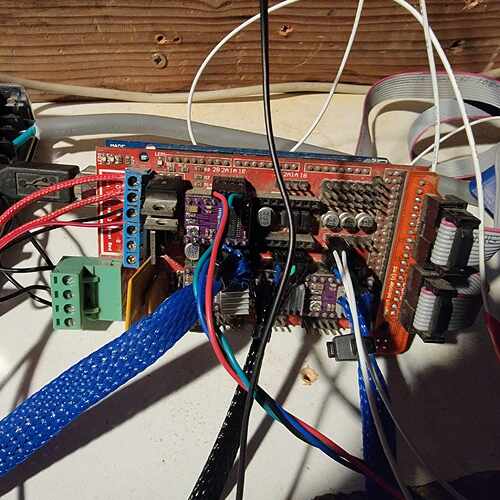

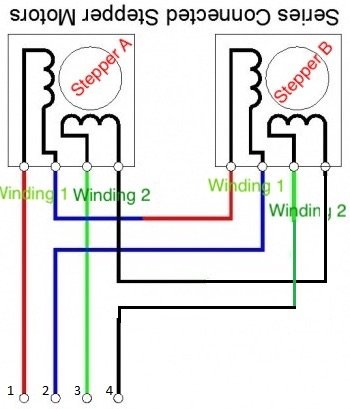

Possibly series wiring used for 4 driver boards. It puts 2 steppers together on each axis. The only downside is that you can’t use end stops to auto square your machine.

What kind of wiring would I need to do to use end stops on the X and Y axis? I’m going to assume he wired the other set the same way.

Each stepper would plug into it’s own driver at the board. It seems your board is missing a driver in one slot. The 3d print head makes me think he wanted space to plug in the extruder.

That’s correct. I don’t have the 3D printer setup right now because I wanted to get the basics solid and make sure it’s working before I move onto something more complicated like actual 3D printing.

But from what you’re saying, each stepper would have it’s own dedicated driver, each with it’s own dedicated endstop?

Perhaps I’ll consider that after I learn how to properly use this setup. My goal is to get the 3D printer up and running after I’m able to do the basic stuff like calibration and the crown test so I can print the pieces that are missing, like one of the router mount pieces, cable chains, etc.

That’s right. For each axis to have it’s own driver along with an extruder would take a 6 driver board. It has been awhile around here since someone talked about using a MPCNC for a 3d printer. There is a MP3DP that is purpose built for 3d printing.

I fixed the wiring and redid it so it’s not just asking to get caught on corners or the pulley track and it fixed the issue with the steppers shaking.

Got the new power supply setup and it’s working just fine, far as I can tell none of the components were damaged when the old power supply failed!

After checking that the steppers were working as expected, I hooked up the extruder to the z-axis.

When first preheating PLA, it started to extrude filament but then immediately failed with a “E1: Heating Failed, Printer Halted, Please Reset” with an ear piercing shriek from the RepRapDiscount Full Graphic Smart Controller.

Since the fan on the extruder was controllable without issue, and the heating element seems to be working, and the extruder stepper seems to be working correctly, my guess would be that the thermistor is either broken or plugged in the wrong way. My plan is to hook it up to Repetier-Host or some other 3D printing program tonight to try and get a temp readout to see if it really is the thermistor broken.

Speaking of, are there any thermistor replacements people would recommend that I can find on Amazon?

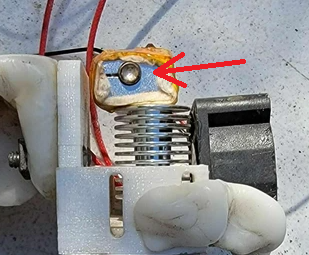

I am a big fan of this kind. A little more expensive and require changing it in the firmware and re flashing. It should fit where the old set screw that holds the current one in.

are you talking about this set screw here?

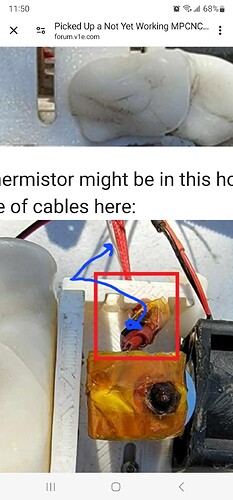

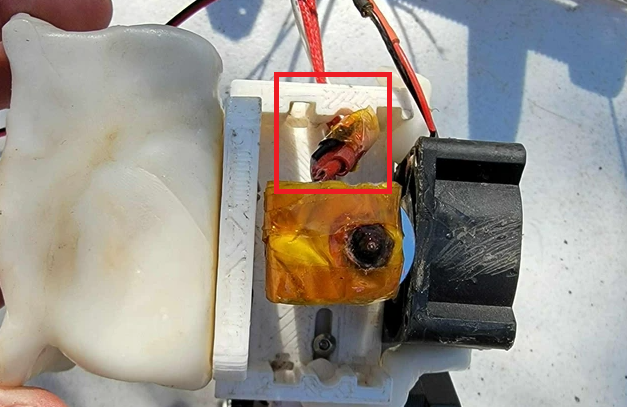

I think the thermistor might be in this horribly wrapped pile of cables here:

I probably need to do a tear down on this thing anyway. Also what is that amber looking tape currently wrapped around the block?

That’s Kapton (polyimide tape) or a cheap clone of it. It is a high-temp tape, and in the past was used this way. Today most hot ends us a silicone sock or have the nozzle/heater block in a thermal enclosure.

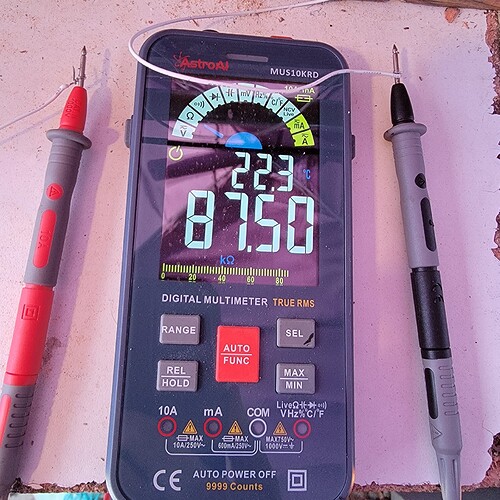

You don’t have to put it on another cotroller. You can pull the connector off, and measure the resistance with a DMM at room temp and tell us what you measure.

is it worth me doing a full tear down of this whole printing head to give folks a better idea of what I’m dealing with and possibly what to replace with modern parts?

Also what do you mean by DMM?

oh you just mean a digital multimeter, got it. I’ve got one of those.

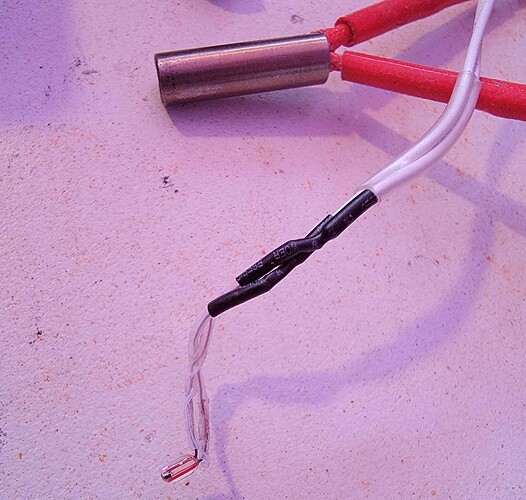

This white wire with the black heat shrink on the end hold the thermistor, its a little glass bead looking thing that is slid in to the block. And held down in

place a s small set screw

Good news, the thermistor isn’t dead.

If you put your finger on it while taking a measurement, does it show a slow increase in temp?

is it possible this is a firmware issue? I’ve seen this commonly reported for Marlin V2+. And I’m using 2.1.1, or the firmware specifically recommended for Ramps.

Also I can’t tell where the thermistor is unfortunately to be able to put my finger on it. would putting my finger on the extruder head accomplish the same result?

Yes. Warming the heater block will warm the thermistor eventually. I’ve done the finger test in the past - just make sure you’re not testing the heater at the same time.

I have questions.

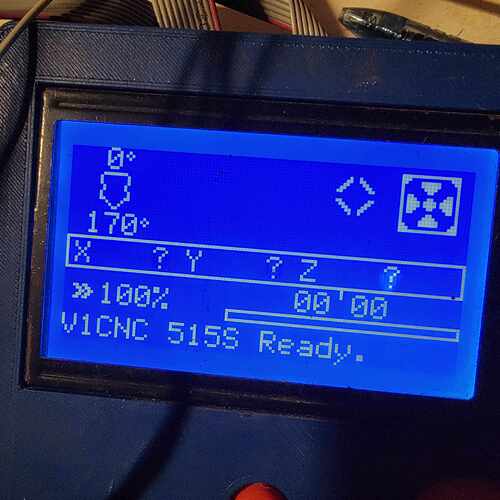

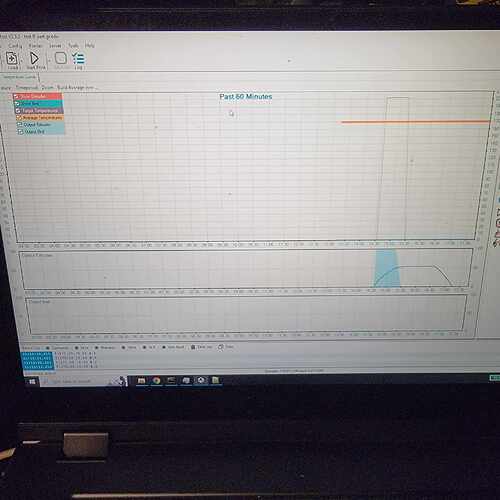

With the 0 and 170 degrees showing there, does my thermistor think I’m already at 170 degrees? Or is that the required temperature to hit before the print can begin?

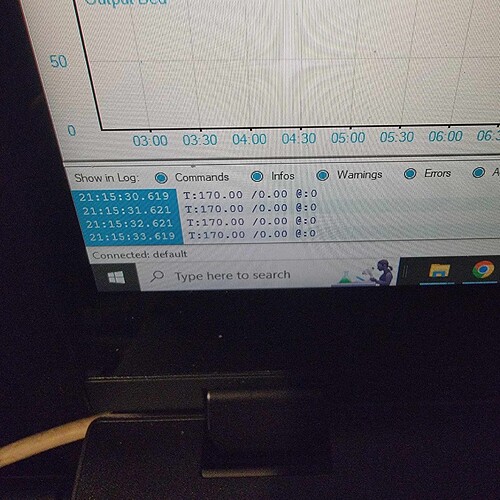

If you look at the log from repetier you can see that graph for “output extruder” barely hits 50 C before it starts going back down again.

at the same time, the nozzle is getting hot enough for filament to start leaking through the tip (from the previous owner) does this likely mean my thermistor needs to be replaced?

That’s the target temp.

So what do you think my problem here is?

Is my thermistor bad?

Is my heating element not getting enough power?

Is this a bug in the firmware?

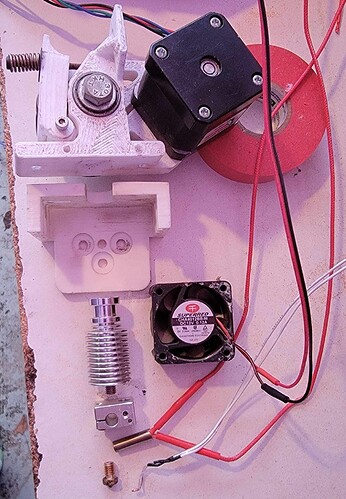

I decided to do a full teardown so I could see how the 3D printer head is constructed. Thankfully, nothing was permanently in place.

To start, here is a full teardown.

The heatsink is friction fit between the extruder assembly/stepper and a mounting piece.

The extruder fan then blows directly on the heatsink as so:

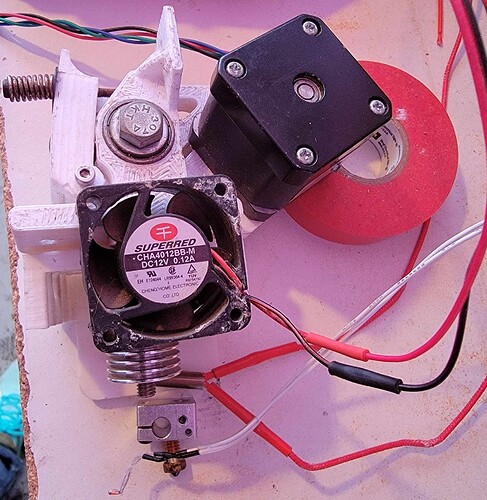

Here is the heating element and thermistor.

Closeup of the thermistor

I’ll make another reply for the heatblock.