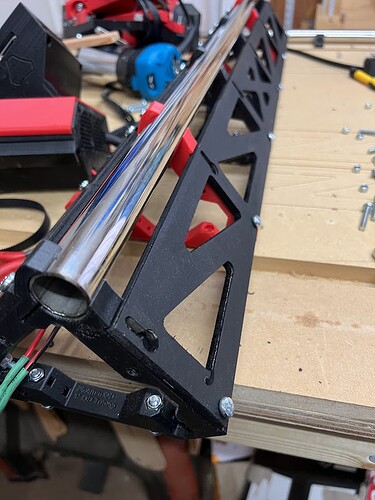

Lots more progress has been made. I finally got in the correct linear rails, and installed them along with my nice lowrider cut and sprayed black 6mm mdf strut plates.

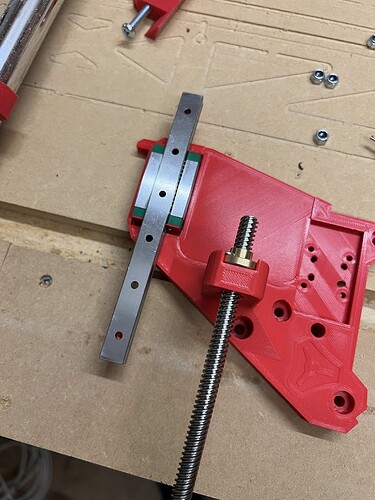

I then had some issue with my Z axis grinding… Checked everything from this excellent Faq thread, Z Axis Troubleshooting

and thought I had checked everything. However I was using the silicone spray, which it turns out is not good. The PTFR grease seemed to do the trick, as soon as that was applied to my Z axis it was smooth sailing all the way.

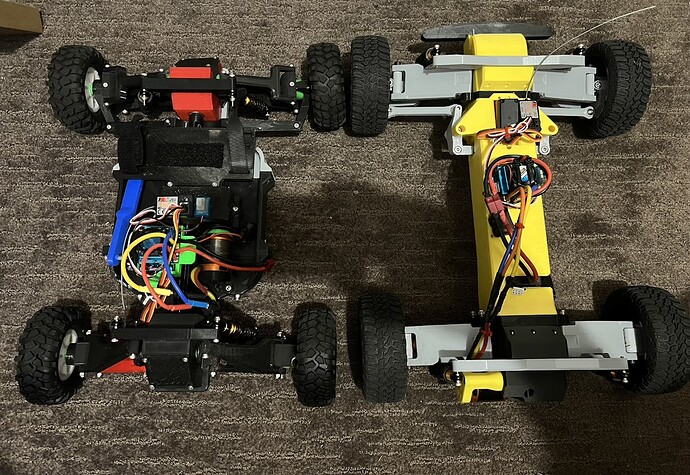

I had the PTFE lube on hand from my previous Mostly 3d Printed fun with Tarmo4 and Tarmo5 RC cars.

Great community around these cars here: Tarmo5