How is “performance” defined?

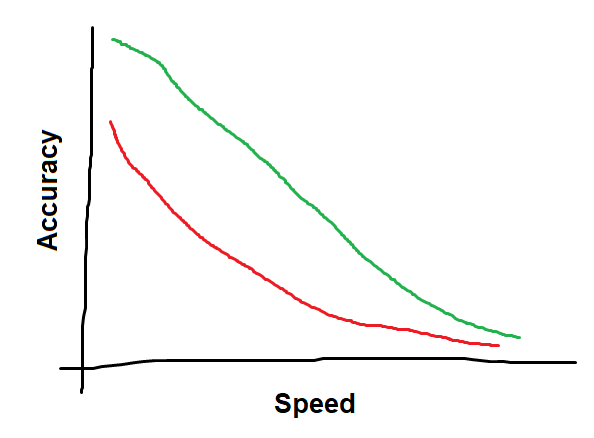

I think a reasonable definition would be an envelope of accuracy vs. cutting speed, sort of like a ROC curve (if you’re into that sort of thing). A given machine will be able to cut faster with lower accuracy, or achieve higher accuracy with slower cuts and finishing passes.

Two machines might have different achievable accuracies at different speeds (and it would depend on size among other things).

Here is an example where the green curve represents “higher performance” than the red curve, although the machine that produces the green curve might be only 12" x 12" while the red curve is from a 4’ x 8’ machine:

Accuracy is driven primarily by the stiffness of the machine, which I think is what Ryan was getting at earlier. The machine doesn’t “break” when you load up with high torque and high speed, but if the deflection is large and accuracy is poor, you end up with a junk part and the frame has failed to do its job, but not because it was near breaking.

Higher speed rapids could definitely contribute to the overall speed in completing a job (depending partly on what the job is).

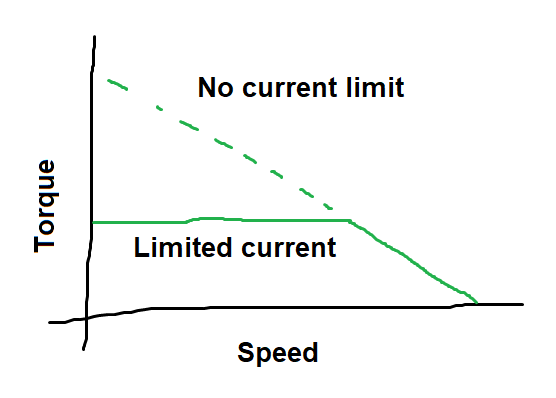

Now I’m also thinking that a roughing operation could really push the spindle, machine frame, and steppers to their maximum, and blast out a ton of sawdust (or whatever) in a surprisingly short amount of time. This would be a scenario where you’re beyond the usual loads where the frame retains its usual accuracy, and you would really not want the steppers to skip steps for example. This is the situation where the stepper torque at speed could actually matter a lot.

For any sort of accuracy at all, the torque and speed will be light and slow, and the performance (meaning speed vs. accuracy of the finishing pass) is 100% driven by the stiffness of the frame. A stiffer frame can support slightly higher loads and maintain the same deflection, meaning either higher feed rates or deeper cuts, both of which decrease the time to complete the finishing operation. Motor torque and speed are not factors in this regime.

I think mentally, people (at least for me) tend to think primarily, perhaps even exclusively of the slow, precise, and lightly-loaded operations. I would venture that this is the reason for the push-back, since the available stepper torque and top speed do not contribute at all when operating in this regime. As long as I can get the accuracy I want and the speed is “fast enough,” I’m happy.

Roughing speed and rapids are valid things that do affect overall performance (according to my definition), especially if you are trying to push the throughput to the limit. But outside of a drag race, most are not concerned about throughput, so it is rare that they get attention.

I realized that it comes down to that constant current driver. Again.

I realized that it comes down to that constant current driver. Again.