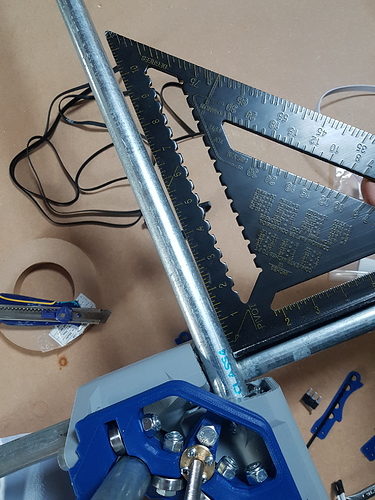

Just started my mpcnc build. Have this issue of not being able to square up the xy. Anybody have any ideas. Nothing is over tightened. Could the print be a bit off?

Uea, the prints could be off. X/y can be square, but your z might be leaning.

There are alignment screws that tighten or loosen certain bearings to fix those issues according to the assembly instructions. But I too was unclear as to which ones to adjust in order to align in in which direction so I haven’t done that yet either. Hopefully someone that understands the process will chime in here.

It could be a goofy print. When the motors are engaged, the two ends will move in lockstep. So I would just clamp some blocks on you can hold the gantry against when starting. They should be placed so the gantry is square and then the motors will keep it square. After some use, you can take a closer look at this issue.

One of my gantry spacers slipped a little out of place while I was tightening the 5 inch bolt and I had the same issue. Loosened a little, snapped it back into place, and boom, pretty square. You might try loosening that long bolt up and see if the angle changes, maybe the ones that hold the assembly together from the sides, as well. If it goes square while it’s looser, but gets crooked as you tighten it, you might get some clues about what’s causing the crookedness. Otherwise, like Jeff said, if you can square it then power it on, it’s a non issue. If you’re going dual endstops, same thing, it just squares after powering on.

My gantry is also off square, similar to yours. I printed the gantry parts several times, trying to get them as precise as possible. I even printed the xy parts 180 degrees rotated, so that they would even out each other - in case something was wrong with the print. I changed parts and worked the threads on the bolts against the part holes, to make them run smooth. Still out off square, with all bolts fully loose. After being told a hundred times to “get it dirty”, I ended up assembling it - and was relly suprised by how well it turned out! It’s still out of square when motors are unpowered, but using hard stops I square the moving rails (and thus gantry) and power the motors. (using cncjs, making a custom macro, very convenient)

I honestly don’t understand why it didn’t work out - I spent so much time troubleshooting and re-printing. Now I’m happy that I assembled it, and it works very well when as it is. I’m looking forward to Ryans new edition, and planning to make it right then! I could re-assemble the gantry now, it’s said that it often sorts out the skew, but I’m honestly cool with waiting for a new MPCNC version.

Thanks for the replies fellas.  . I’ll get cutting as soon as I have the spindle in place. See what it cuts like:crossed_fingers:.

. I’ll get cutting as soon as I have the spindle in place. See what it cuts like:crossed_fingers:.

One thing I would check is that the spacers didn’t rotate while you were assembling the XYZ behemoth. That might force it out of alignment and isn’t necessarily obvious.

Glad I’m not the only one!

I think i’m just going to run it for a while and see how i get on. Dont need it super accurate at the minute, so…