Yeah. I should be able to cut something like that into my clamps.

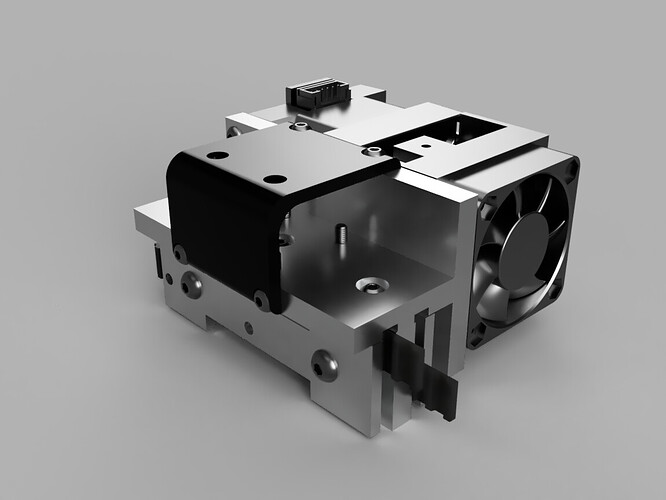

Here’s where I’m at with my design. Any thoughts are welcome before I start cutting metal.

Two big edits I did…

-

I notched the underside of the horizontal piece so that those belts can be moved up a bit. Comparing my test assembly to the stock core, it looked like the belts needed to go higher.

-

made the belt clamps taller so the bottom belts could be moved down some. Same reason as above. The stock core looks like the belts were lower. I also then notched the clamps on the bottom for wire clearance from the hotend.

Well… I guess there’s a few more edits. I flipped the clamp bolts around and made them M4. The original design had M5. I’ll thread the back clamp and use that to pull the clamps tight.

Thinking about putting the assembly together in my head, I think I can now get to all of the bolts as needed.

- bolt clamp base to horizontal

- attach horizontal to bearing block

- loosely bolt clamps to clamp base

- attach front to horizontal

- bolt extruder to front

- slide in belts and lock down clamps

- attach plastic wire management and zip tie wires

I do think I want to try to mimic Ryan’s zip tie slots onto this. Right now I just have holes in the top for threading zip ties.

I’m printing copies of all the parts now to test fit again.