Frustration is finally creeping into my voice ![]()

Intermittent is the worst. Try some air cuts and see how it handles with some real motors.

So we had a couple boards, 3-5, that had pins in the driver sockets that were in the wrong spot. So they would short together. I that was around the time you got your board.

So maybe popping the drivers back in moved the pins just right, so they are not shorting anymore, if it happens again I am not scared to pop off the shields to fix them, and I will trade you boards.

It was short lived. I think I’m done. I’ve spent entirely too many hours on this thing. ![]()

When you had this sent back, did you get the Jackpot only or did you get everything?

At this point I’m not sure what to make of it. If this board were one of mine, it would go on the test bench as something really funky is going on.

It was the board+esp.

Board, esp, and drivers.

Remind me on Monday and we will swap it out.

In my head I see the board as it, the esp and the drivers all attached :laugh:

Also, reminder.

Has anyone with a known good working setup tried running this test? I assumed FluidNC would throw an error if the motors were disconnected.

The board doesn’t seem to care. If you $ss it, it will show that it’s missing the motors but in usage it doesn’t throw an error.

Very minor update. I’d planned on holding off until I actually made the machine do some work, but other projects have stepped in line so the wood working is on back burner. No saw dust in the garage for a bit, I just cleaned it and will be painting my sons jeep over the next week. Dust can fly again once that’s done.

So replacement board is in and I’ve made quite a few air cuts, lots of jogs, squaring etc and so far everything looks good. I switched from AP to STA and haven’t run into any issues during the limited runs I’ve done. I’ve run the same files back to back to back and haven’t seen any of the old issues pop up.

So thanks to ryan and everyone that has pitched in with info and advice.

I’m glad you’ve finally got it running well.

I’m also really curious what the deal was with the last one being such a problem.

I’m guessing i built it on top of an Indian burial ground…

Beyond that no idea. I ran it with no problems a bunch. Well no non user caused problems anyway. Then it started dropping (making up numbers because i didn’t actually track) every 10th time i ran, then 5th and then every other until it wouldnt work at all.

Hey just wanted to follow up. I just figured out what was wrong with your board.

The power connector, both positive and negative sides, had gotten overtightened and broke the solder joints.

The issue is bad connection with power. Touched them with a soldering iron and all is good.

This is the second board to have this happen (out of more than 1200 at this point). The sockets themselves need very very little force, they get clamped in with a wedge. I will put a note in the instructions and will be looking for some sort of new connector, maybe the wago style. That I have seen, or the other spring loaded style.

I fixed one of mine that broke this way.

You should consider having the connector bonded with some epoxy glue around it or switch to a connector that mechanically retains the terminal block body without needing the through hole leads to do it.

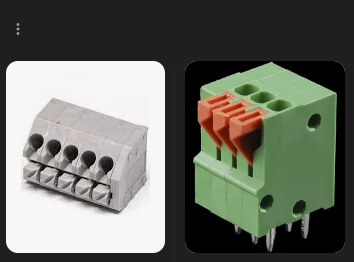

I bet one of these is less expensive, and probably easier for the user.

I can swap out the other ports as well to get rid of the need for a tiny screwdriver.

Wow. I don’t think I was very aggressive with those little screws but my fine turning might not be as fine as needed. That would explain the intermittent nature, I’m guessing between just moving around a bit and a little bit of heat was killing the connection.

I like the push/snap connections better. It would become more or less tool-less install with those.

I prefer the super solid screw terminals myself, but if we swap to push terminals I will need to emphasize people securing the wires more. You would not believe how many people have issues with plugs coming loose because they did not secure any of the wires near the board.

I am pretty sure this will be a good change.

Considered fewer connectors that terminate more pins, so harder to over torque. Also, using larger 3.08mm instead of 2.54mm for screw terminal connectors (harder to strip, but easier to torque, maybe that’s bad)?

Nice pics and instructions on how important strain relief is seems like good idea.

I’m on the fence about this. I really like spring compression terminal blocks but understand why other folks like screw compression.

For applications like the one on the Jackpot, I’ve used this style in the past- note the anti-spin studs in the design. You put through holes in the PCB that accomodate these, and then you can’t break the solder joints while torquing the screws.

Oh heck yeah a win win!!