Hi, all. I’ve been reading through the troubleshooting posts, and have some ideas I can try, but could use some advice.

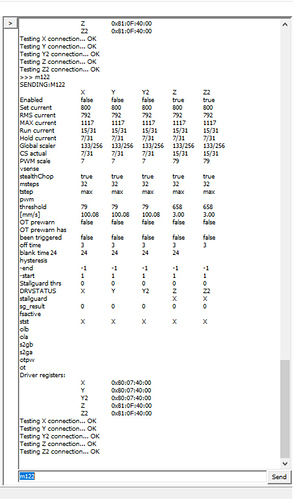

My LR uses an SKR 1.3 with TMC5160 drivers and the dual endstop binary compiled by @nightlink. I’m using that firmware as is, since I couldn’t manage to compile it on my own. I have not made any Vref adjustments.

A few days ago, I tried my first cuts on plywood, and at one point the router really dug in deep on the far side of the workpiece. I noticed that the flexible coupler for that Z motor was sprung/stretched afterwards. Maybe that was the beginning of my problem.

I’ve attached videos below, to illustrate what’s happening. It’s intermittent, but happens more often than not. The far side Z motor seems to miss steps, and even sometimes turn the other direction, when I am raising the gantry. This can happen at either 1 mm/sec or 10 mm/sec, and seems to happen somewhere in the range of about 20 mm from the home position. In one of the videos, you can hear that the motor seems to struggle/skip even when going down.

The gantry falls on its own with power off. The leadscrews are lubricated, and the leadscrew on the far side is nice and straight. The leadscrew and motor turn very freely in that trouble spot with the power off. Grub screws are tight. Leadnuts are loosened. I know that the XZ Main does not sit flat. I’ve read @barry99705’s posts about correcting that, but could not grok his instructions for loosening and twisting components, so I just shimmed the endstop switch on the near side so that both XZ Mains sit the same, small distance above the YZ rollers when homed.

Of course, all of this is happening just as my middle son is getting ready to move into his college apartment and has asked me to make him some flat pack furniture…

I’ve seen mentions of adjusting the max feedrates for the Z motors, but not sure if that’s my problem. thanks for reading this far. Here are some videos of the issue:

https://www.youtube.com/watch?v=hVaa43lXpT4

https://www.youtube.com/watch?v=SeptKkfg4fE

https://www.youtube.com/watch?v=XFtnShiQeVE

https://www.youtube.com/watch?v=udkbraHW6Bs