I’ve been able to make a little progress.

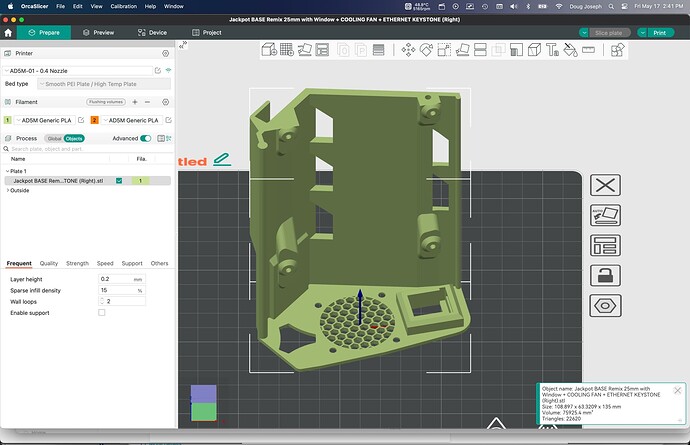

The first print (Where I lowered the base -.02mm ) failed.

It popped off the build plate and spaghetti-ified.

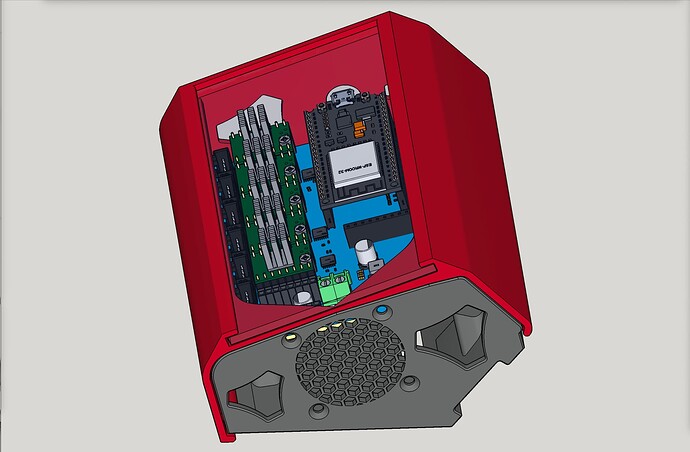

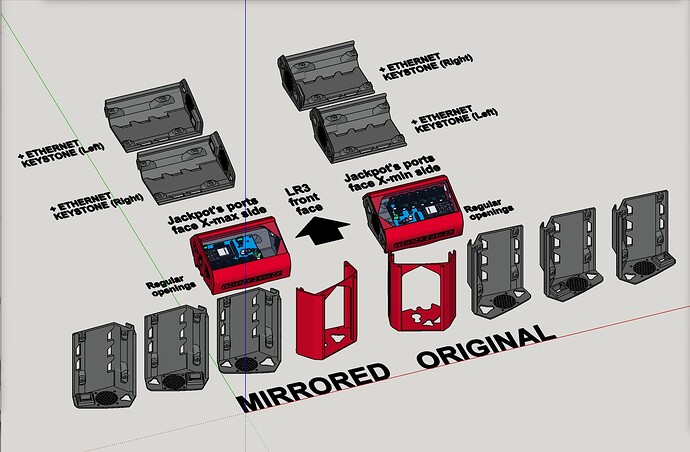

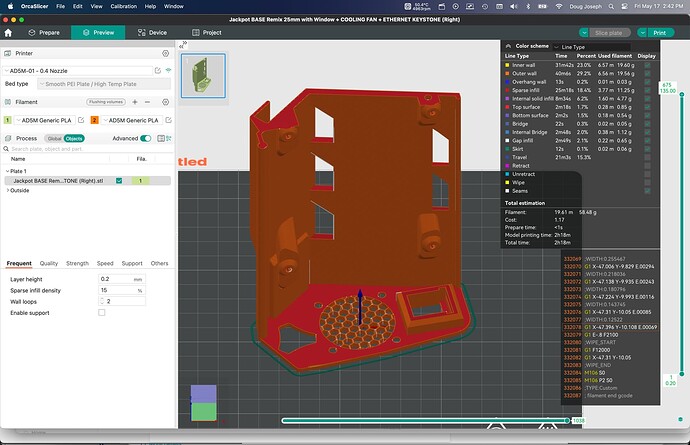

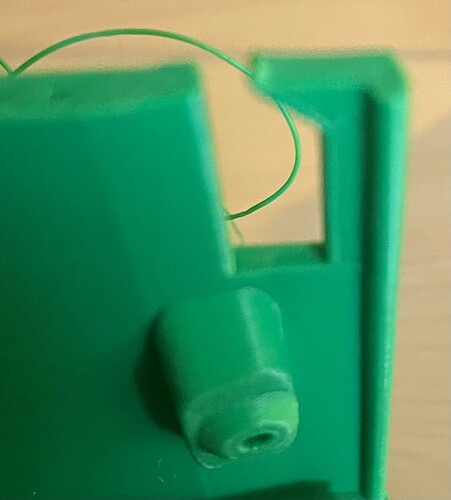

The reason for that (Aside from needing even better adhesion) is that there is upwards curling happening on the overhang shown below. Top right of the print has an upwards curl.

I didn’t orient this one the best way, as the FFCP is dual extruder and if you don’t keep such things out of the Y axis line, then every curl gets hit by both extruders multiple times per layer.

For narrow, tall prints this eventually pops the part off the bed.

Couldn’t get this to focus, but you can see the tip of the curl where it finally caught hard and popped off the bed.

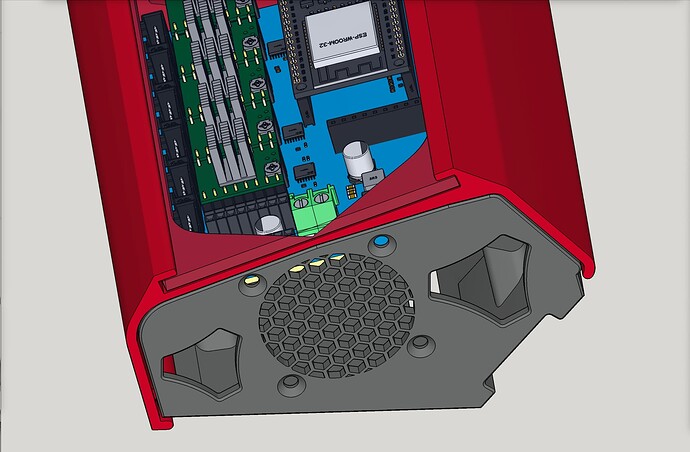

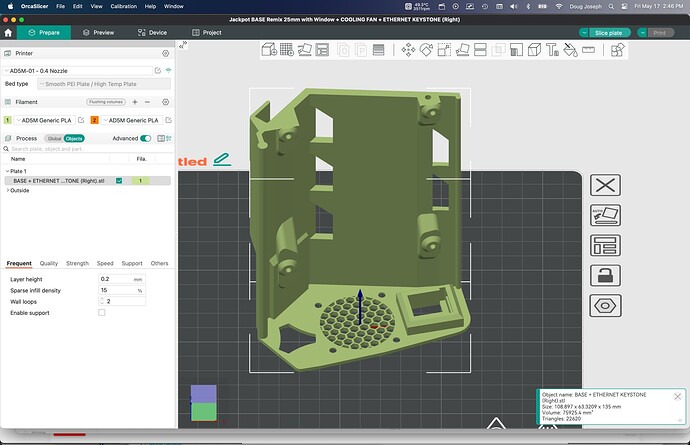

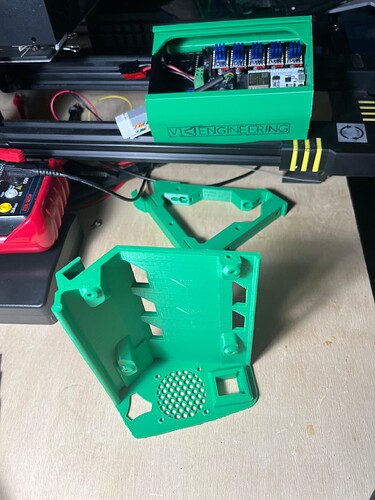

As you may be able to see, the keystone jack port looks great and printed very well.

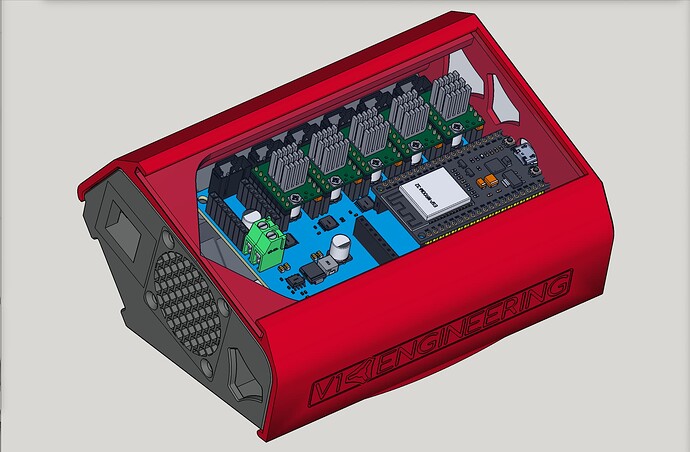

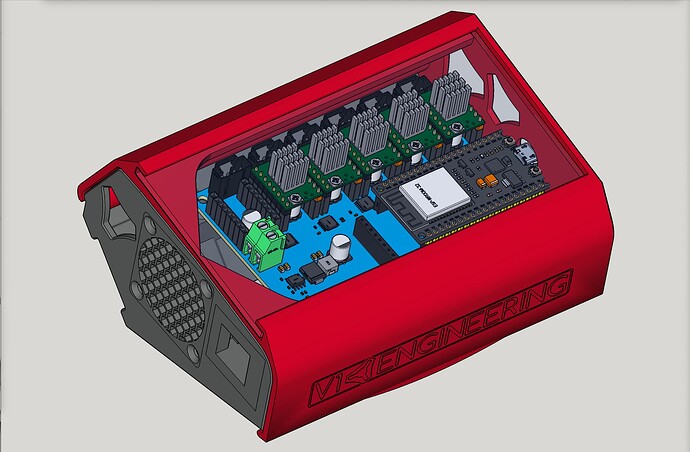

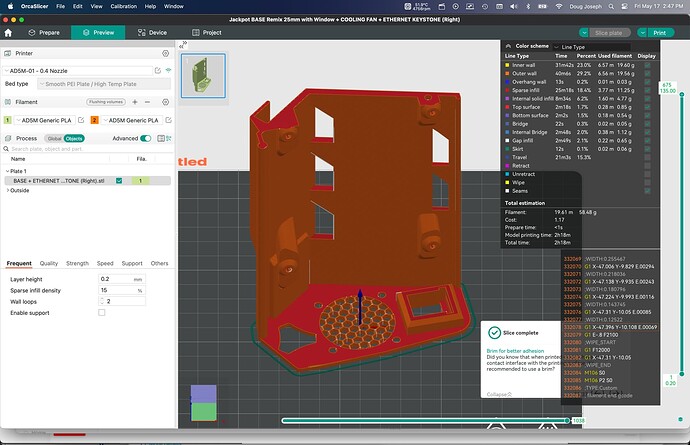

I re-oriented this and started a fresh print with a brim. It looks great, and I’ll fit a jackpot on it late today.

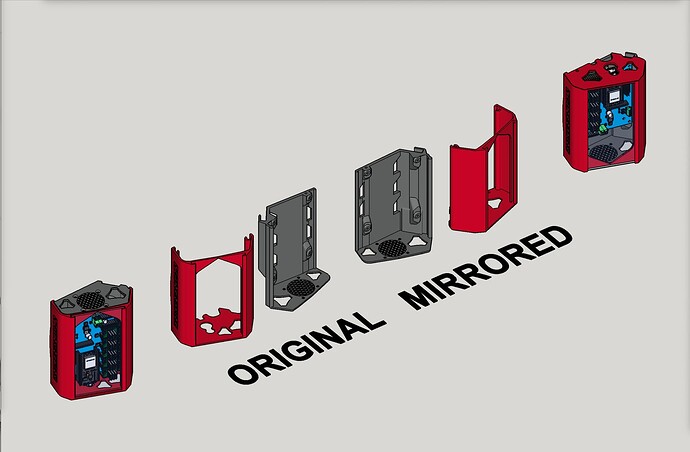

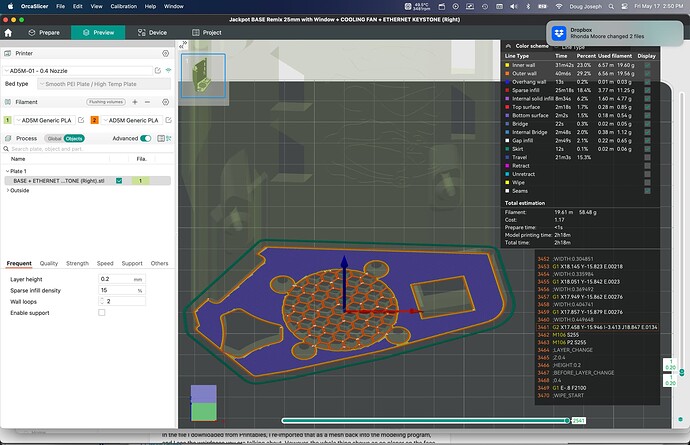

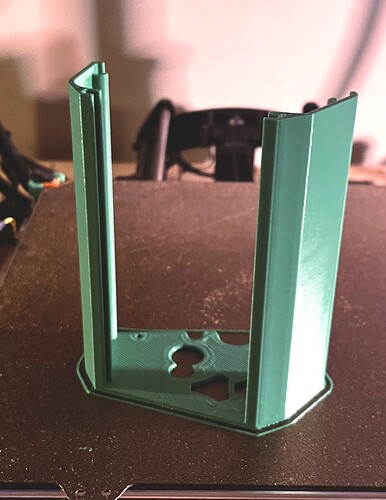

I was going to print a new lid, but realized that there is the same issue.

The added feature to close out the top of the lid will probably ensure repeated print failures for me for the same reason- long overhangs that will curl.

Since it’s at the very top of a narrow, tall print, this will be worse for me than not having a part closure.

The previous lid without that feature printed quite well as can be seen in the picture above of the v1.1 case.

If you zoom in on the top left of the previous lid design, you can see the curling starting to happen in the overhang portion. The previous lid design just didn’t have that overhang long enough for it to be a problem.