You’d have to use CA glue so that it could dry quick enough to be ready for the second layer.

It’d take a whole day for 1 layer so no problems there.

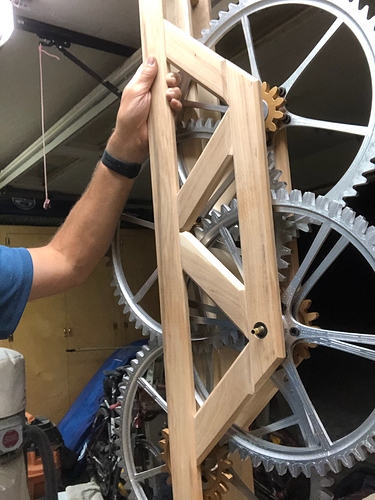

I’m in San Jose, so you’ll have a local guy flushing out MPCNC 2020 as soon as I can download and print it. I have the perfect project that needs a little more stiffness. In the previous picture you can see a fireplace. I designed a clock/kinetic sculpture that hangs on the wall. The 3D printed gears are too light and hard to keep planar, so I’m going to use the MPCNC to cut new gears. See photo of the 3D printed prototype.

Oh I can not wait to see that finished!

Did you do this in multiple segments and this is glued together? Or is this cut from one piece.

I thought the MPCNC was sort of limited to maybe 48"x48" maximum size and this seems a lot bigger.

if you look at the wood grain you can tell that part is glued together. He just wants to cut new gears with the mpcnc.

How thick are each gear? Rather than cut away a huge amount, it might make sense to get 1/4" stock and laminate instead.

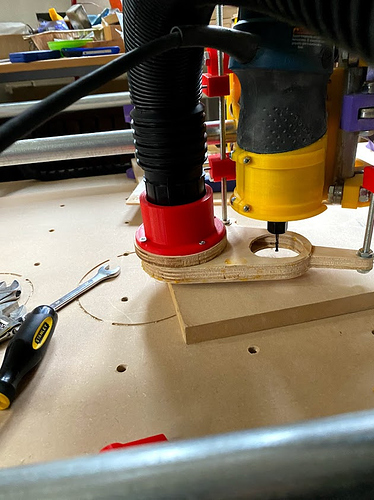

The voronoi panel was done by indexing the cut in sections and pushing the 97" x 34" sheet through a couple of feet at a time and having the G-code for the new index pick up from where the prior cut left off. The machine was built on a 48"x48" base, so it can cut 36 x36, or thereabouts. It’s not very accurate, but for this cut-out job, plus or minus 1/8 absolute accuracy and 1/32 relative accuracy was fine.

When I print out the MPCNC 2020, I’ll cut some new conduit to a smaller size and set up a second “internal” corner - anyway, figure out some way to make it a quick-ish task to switch from the large/floppy to small/tight form factor, depending on the job at hand.

Correct. I’m keeping the hickory wood chassis of the clock and just cutting new gears with the MPCNC 2020. I printed and glued the original gears in 60 degree segments. But the PLA was not very stable and did not glue very well - I kept cracking them apart. Also, they did not print out totally accurately and so the glued gears ended up with a slight bowl shape so they did not fit in their lanes to mesh properly without scraping against gears running at different speeds in different lanes. Occasionally it would decide to lock up and that made for total chaos. A clock as a huge reduction ratio - so a one pound pendulum generates a lot of torque by the time you get to the hands, easily breaking teeth off a locked-up gear train.

MPCNC Focus Edition

As in 20/20 vision.

MPCNC Hindsight.

Hindsight IS 2020.

I love focus but that is a major CNC company.

I immediately associate Focus with Ford though, and that’s … not ideal.

Maybe Create, or Creator, something along those lines. I think it’s been suggested already though.

Just tore down my MPCNC to prepare to build the incoming update. After which I realized my lowrider is torn apart too and I don’t have an operable CNC.

So, Ryan… I have antsy pants, when can I order some parts?

Makes me think of carbide create and shakeopo

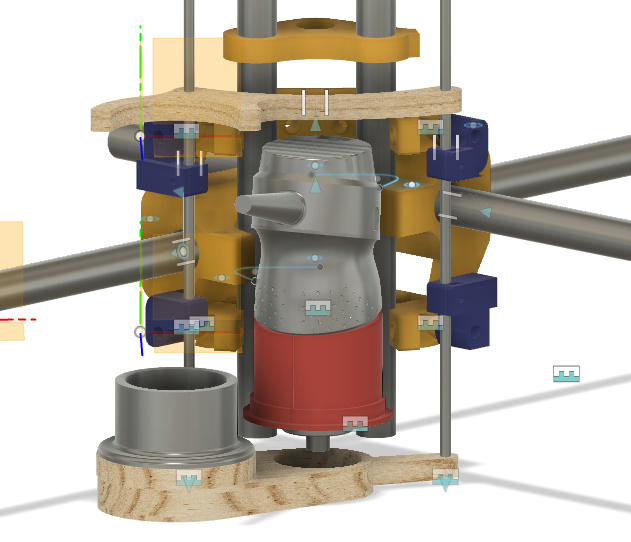

Oh no, I just modeled the xy and xyz assembly and modeled myself some dust collection.It would be great if the new design had a recommended dust collection approach. I was inspired by http://www.thingiverse.com/thing:2597409 but modeled it in Fusion 360 and made the brackets a little more organic (though they are still not super beautiful)… But it does make me more happy to use the CNC as it doesn’t spit dust everywhere.

I used to do that with re named files that happened often. There was .old .lessold .evenlessold .damnnearnew it got to be fun and only my colleagues would ever see it.

I am still not sure where I stand with this. You will always loose some accuracy strapping a vac hose to the gantry, and a little build volume. I have made some lower screw holes to mount to for thin mounts, and maybe I can provide one at some point but it is not a huge priority for me. I use my MPCNC for accuracy and my LR for large parts with bigger tolerances.

I think you are right if the major versions have a unique name

but if you add small fixes in the meantime somehow you have to note the users

For example, Ubuntu Linux have codenames and semantic versioning at the same time

so you can call it for example

mpcnc bustard v3.1.1

I just decided to build one so I am so excited about the new version

thank you for your great job

I had some resource recently about the weakness of the mpcnc

as I see one of the most serious is the belt size and the tension.

Can you add a proper belt tension with an easy to upgrade to a wider timing belt for example up to 15 mm

it can be more rigid closer to the lead screw

the problem:

youtu be/vi-lGsx-Qms?t=2299

the best solution what I found solve both problems

youtube com/watch?v=AFthTuSSD8E&feature=youtu.be&t=393

he cutting 15mm aluminium like a pro

youtube com/watch?v=zefnrPRvc9Q