But could that really be because the site specifically says of using dual endstops, “People new to the CNC world should not use this, this is a advanced technique…” and “I highly recommend you start with the series wiring kit. The dual kit adds complexity…” which steers them in that direction and scares them away from going with dual endstops (in my opinion, needlessly so)?

Search M119 and see how often people have an issue plugging in endstops and that is not even making the proper gcode to use them.

I believe it is best I make the option available but gear the instructions and kits towards the lowest barrier to entry.

I don’t use them on a regular basis so I do not think they should be standard.

With that info, I don’t use bed leveling on any of my 8 printers either. For me it is easier to turn a screw to level the bed when there is an issue than tune each of the offsets every time I flash. For me Dual endstops are a lot like that. I spend time to ensure I build it as square as possible and take a second to check it before I hit start. I rather hit it with a tape measure when I hit go than deal with offsets in CAM. If I repeat the job a month later then I need to make new cam to get new offsets, that is not how I work. I slap something on the table then hit go, nothing I build cares about 0.1mm accuracy. That is not fun, that is work.

I am a mechanical engineer so mechanical solutions make the most sense to me. Not saying there is not a time and a place for more accuracy (warped print bed, multiple tool changes, multiday jobs).

I had a guy here (older) yesterday and he was so excited at the possibilities of a CNC but was petrified of the “Math” involved, not actually building it, he though it looked simple. I told him there was no math involved, he asked if he could just draw me plans and cut things out for him. That is my target audience the older folks, young folks, people intimidated by tech. I want them to experience the easiest path to drawing a crown.

From that point on, the world of CNC has opened up. Maybe it is laser etching, maybe cutting stickers, milling, chocolate extruding, printing, plasma. I am trying to open the door not provide diploma’s.

Crown lasered into goatskin = V1 Diploma. Removal of skin from goat optional.

Can you imagine just how complex you build needs to be for the laser to stay focused on a live goat? Talk about a warped build surface…

He never said live…

Auto Bed Leveling would be the preferred method here. ![]()

Why can’t you just train the goat to keep it focused.

Goat? Focus? Totally incompatible. Guess where the terms “capricious” and “caper” come from.

Italian? Latin?

Technical term for goat-related is caprine (like canine for dogs etc.) Also Capricorn the goat. Latin root is “capra”.

Just for my edification, is there some cunning reason why the three screw flanges on the Primo C Feet are all slightly different thicknesses?

So that not all the stress is on the same Z layer, IIRC.

Hi Barry, Im in the same boat of needing hardware for the Primo… any chance you could forward your parts list so I can just have them re-order for myself.

Thanks,

skill_cap

Sounds reasonable, thanks for the info. I’ll consider that on my own print designs.

I guess the flange to body join is also a stress concentration hot-spot, but I’m less familiar with allowing for the non-homogeneous nature of 3D prints.

With him you need to read between the lines.

Lol

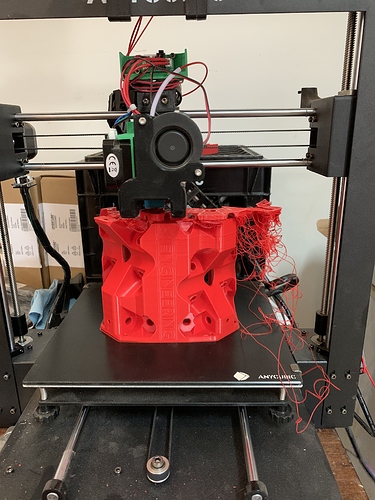

Edit: after close inspection of the crime scene, I found a mid roll tangle must have yanked the spool from its perch

WOW! I’m impressed that it was able to recover as well as it did

Yeah, not a bad overhang on that

From my experience, that “mid” roll tangle started at the beginning. When i’m handling a roll, i get so distraught if the end of the filament gets away from me. I’ll end up un-spooling about 15ft to confirm that it didn’t get tangled before i thread it in to the machine.